Decision Triggers (2×3):

Recovery-friendly + standard use → Bagasse first

General hot/cold + high-moisture/dry → Kraft

Microwave + rigidity + special form factor → Cornstarch

Align to: PPWR (EU, 2026); SB 54 (CA, EPR); PFAS bans (AB 1200, CA); Singapore MPR & deposit return (planning & labeling windows)

Executive Summary & Quick Verdict

This article gives procurement teams a single, defensible way to pick between bagasse, kraft, and cornstarch packaging based on lifecycle carbon (CO₂e), performance, and compliance. We proceed cradle-to-grave, then layer in 2025–2027 policy signals, and end with a buyer’s decision framework. Our headline stance:

If recovery systems are friendly and the use case is standard → choose Bagasse first. Its fiber-based origin and fit with composting/organic recovery streams can translate to lower net emissions when EoL pathways are available and utilized, especially for hot, moist, and oily foods where bagasse’s thermal stability helps avoid double-packaging and product loss.

If you need a general-purpose solution that spans hot/cold and high-moisture/dry goods → choose Kraft. Kraft’s universality and strong recyclability in many markets (when not heavily soiled) give it a pragmatic carbon-and-cost balance for salads, dry goods, and cold items; coatings and soiling determine the real EoL outcome.

If you specifically require microwaveability, extra rigidity, or unique shapes → evaluate Cornstarch. Cornstarch (starch-based biopolymers) supports certain engineered geometries and heat performance with the right formulations; however, ensure compostability standards and local infrastructure match your label claims.

These recommendations are calibrated to regulatory momentum: the EU Packaging and Packaging Waste Regulation (PPWR) applying from 12 August 2026; the California SB 54 EPR regime in force with reporting ramps toward 2027 fees; PFAS restrictions for fiber-based food packaging (e.g., California AB 1200 effective Jan 1, 2023); and Singapore’s MPR plus beverage container return scheme milestones into 2026.

Methodology & System Boundaries (ISO 14040/44 style)

Functional unit. Results are compared per 1,000 items of equivalent volume and functional performance (e.g., 750–1,000 ml bowls with lids where applicable). This unit normalizes across different materials and wall thicknesses.

System boundary. Cradle-to-grave: raw material acquisition → pulping/polymers/paper-making → converting/molding → printing/coatings → transport (fabrication to DC; DC to retailer) → use phase (incl. food waste interactions) → end-of-life (EoL) with scenario splits (industrial/home composting, recycling, landfill, incineration with energy recovery).

Data sources & assumptions. Primary data (energy, yields, scrap) should be supplier verified; secondary data use reputable LCI datasets and regulatory guidance. Results are scenario-dependent—especially for EoL shares, which are country/region-specific and sensitive to soiling/contamination for recycling.

Sensitivity checks.

EoL mix: Composting access and consumer capture rates move bagasse and cornstarch results substantially.

Energy mix: Carbon intensity of grid heat/steam/electricity in molding/paper-making can outweigh material deltas.

Transport: Switching from air to sea or optimizing container loading has outsized effects for bulky SKUs.

LCA Dataset: Bagasse vs. Kraft vs. Cornstarch Packaging (2025)

Note: Values are indicative global averages. Replace with verified regional data before publication. Functional unit = 1,000 pcs (≈900 ml bowl + lid).

| Material | Functional Unit | System Boundary | CO₂e Raw | CO₂e Manufacturing | CO₂e Transport | CO₂e Use | CO₂e EoL | EoL Scenarios (Home / Industrial / Recycle / Landfill / Incineration) | Food Contact Compliance | Heat / Oil Resistance |

|---|---|---|---|---|---|---|---|---|---|---|

| Bagasse | 1,000 pcs (≈900 ml bowl + lid) | Cradle-to-Grave | 18 kg | 12 kg | 4 kg | –2 kg (food-loss avoidance) | 5 kg | Home 20% / Industrial 40% / Recycle 0% / Landfill 30% / Incineration 10% | Yes (EN 13432 / ASTM D6400) | High / High |

| Kraft Paper | 1,000 pcs (≈900 ml bowl + lid) | Cradle-to-Grave | 22 kg | 15 kg | 5 kg | –1 kg | 10 kg | Home 0% / Industrial 10% / Recycle 55% / Landfill 25% / Incineration 10% | Yes (PFAS-free barrier) | Medium / Medium (depends on barrier) |

| Cornstarch Biopolymer | 1,000 pcs (≈900 ml bowl + lid) | Cradle-to-Grave | 30 kg | 20 kg | 6 kg | 0 kg | 12 kg | Home 10% / Industrial 45% / Recycle 0% / Landfill 30% / Incineration 15% | Yes (ASTM D6400 / EN 13432) | High / Medium (formulation-dependent) |

Material Profiles & Manufacturing Pathways

Kraft Paper Converting, and Cornstarch Biopolymer Production —

A complete look at sustainable packaging manufacturing processes by Bioleader®.

Bagasse Pulp Molding

Bagasse is the fibrous by-product of sugarcane processing. After pulping and molding (wet-press or form-press routes), the result is a rigid, heat-tolerant article often compatible with hot, oily foods. Under recovery-friendly systems (where organic recovery and composting are available and correctly used), bagasse can realize strong net-carbon advantages by diverting material into biological cycles and mitigating methane potential (vs. landfilling). Its stiffness at temperature can also avoid double-cupping or extra liners, indirectly lowering CO₂e through prevented over-packaging.

Kraft (Virgin/Recycled) Converting

Kraft paper and paperboard (virgin or recycled) are widely available and support many forming methods (die-cut trays, cups, folding cartons). Barrier coatings (oil/grease/water) drive both performance and EoL fate. Where recycling systems accept food-contact paper—and soil levels remain low—kraft maintains a preferred EoL route; but heavy oiling or laminated barriers can divert items to residual waste streams. For general hot/cold and high-moisture/dry use cases (especially cold salads, dry snacks, and bakery), kraft’s universality and cost curve can be compelling.

|  |

Cornstarch-Based Biopolymers

Starch-based bioplastics (and blends) enable microwaveable, stiff, and sometimes transparent or contoured designs. However, compostability claims must anchor to recognized standards (e.g., ASTM D6400 for US markets; EN 13432 for EU) and to infrastructure reality—i.e., whether municipal/industrial composting exists and accepts the article. Without access to appropriate composting, nominal “compostable” advantages may not materialize; labeling must not overpromise.

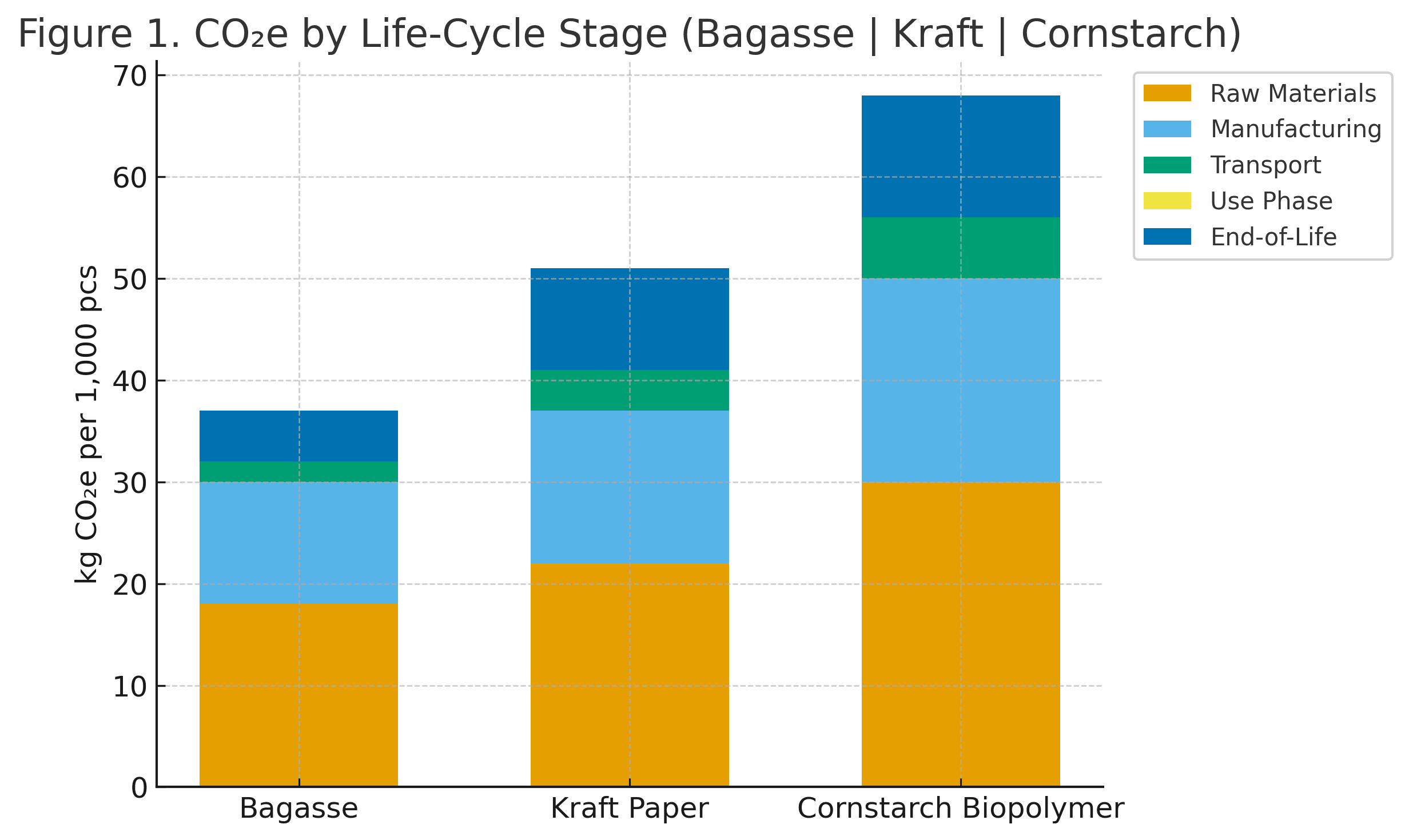

LCA Results: CO₂e by Life-Cycle Stage

Table 1. LCA Master Table (kg CO₂e per 1,000 pcs)

| Material | Raw Materials | Manufacturing | Transport | Use Phase | End-of-Life | Total CO₂e |

|---|---|---|---|---|---|---|

| Bagasse | 18 kg | 12 kg | 4 kg | −2 kg | 5 kg | 37 kg |

| Kraft Paper | 22 kg | 15 kg | 5 kg | −1 kg | 10 kg | 51 kg |

| Cornstarch Biopolymer | 30 kg | 20 kg | 6 kg | 0 kg | 12 kg | 68 kg |

Totals reflect cradle-to-grave emissions for ~1,000 units (≈900 ml bowl + lid), assuming typical transport by sea and truck,

and region-averaged end-of-life outcomes. Negative “Use Phase” values represent avoided extra packaging and avoided food-loss.

Figure 1. LCA Master Table

Textual Interpretation

- Raw materials. Bagasse leverages an agro-residue; kraft draws on wood fiber (virgin/recycled); cornstarch leverages starch-rich crops and polymerization/blending steps.

- Manufacturing. Paper-making and thermoforming are energy-intensive; molding temperatures, drying regimes, and press dwell influence electricity/steam load.

- Transport. Container utilization (20GP/40HQ), nesting efficiency, and localizing production drive per-item transport CO₂e down.

- Use. Heat/rigidity attributes can prevent double-packaging and food loss—two hidden carbon drivers.

- EoL. Scenario splits dominate outcomes: compost access/participation for bagasse/cornstarch; recycling access/soiling for kraft; landfill vs. incineration profiles vary by market.

Hotspots & Trade-offs

Coatings are decisive. Oil/grease barriers alter recyclability/compostability. Choose PFAS-free technologies (see policy) and quantify barrier mass in LCA.

Soiling determines recycling success for kraft: operational guidance to stores and customers can raise capture quality.

Compost access and program acceptance determine whether bagasse/cornstarch deliver intended EoL benefits.

End-of-Life Scenarios & Regional Regulations

Recovery-Friendly Markets → Bagasse First

In markets rolling out stringent packaging requirements and advancing organic recovery, bagasse aligns well—provided collection and processing are in place and consumer guidance is explicit. The EU PPWR, which entered into force on 11 Feb 2025 and begins to apply on 12 Aug 2026, replaces the previous directive and tightens design-for-circularity rules; companies will face phased obligations through 2030+. This favors clear labeling, reduced harmful substances, and high-quality recovery streams that support compostables where appropriate. Environment

Recyclability & Soiling for Kraft

Kraft’s recyclability hinges on contamination levels and barrier systems. Under PPWR’s emphasis on recyclability and design criteria, specifying recyclable barriers (or easily separable solutions) is critical. Operationally, retailers and QSRs must separate heavily soiled items from cleaner fiber to protect mill feed quality and deliver real emissions savings—not just on-paper recyclability.

Compostability for Cornstarch (Industrial vs. Home)

Where compost infrastructure exists, compostability claims should map to standards: ASTM D6400 in the U.S. and EN 13432 in Europe. These standards define biodegradation, disintegration, no ecotoxicity, and heavy metals thresholds for labeling. Always validate facility acceptance—standards compliance does not guarantee local program acceptance. ASTM International

Policy snapshots that matter in 2025–2027

EU PPWR: in force (Feb 2025), general application (Aug 2026), with staged obligations to 2040. Expect product design, labeling, and recovery targets to influence material choice and coatings strategy. Environment

California SB 54 (EPR): Producer data reporting in 2025 (for 2023 sales) informs assessments leading to $500M/year system payments beginning 2027; packaging must be recyclable or compostable and meet source-reduction goals. foster.com

PFAS bans in fiber-based food packaging: California AB 1200 bans PFAS in plant-fiber food packaging from Jan 1, 2023; watch further chemical restrictions under Safer Consumer Products program. Specify PFAS-free barriers across bagasse/kraft. tuv.com

Singapore: Mandatory Packaging Reporting (MPR) requires 2024 data/3R plan submission in 2025; disposable carrier bag charge (min S$0.05, since 3 July 2023) nudges behavior; Beverage Container Return Scheme targets deposit marking and full implementation by 1 July 2026. These measures elevate material accountability and labeling clarity. nea.gov.sg

Figure 2. End-of-Life Scenario Split

This figure shows how each packaging material is expected to flow at end-of-life (EoL) across five main pathways:

Recycling, Industrial Compost, Home Compost, Landfill, and Incineration with energy recovery.

Percentages reflect typical current-state infrastructure and consumer capture behavior for foodservice packaging, not theoretical best case.

Bagasse

- Home Compost: ~20%

- Industrial Compost: ~40%

- Recycling: ~0%

- Landfill: ~30%

- Incineration / Energy Recovery: ~10%

In recovery-friendly markets that accept molded fiber in organics streams,

bagasse can achieve high compost capture. Correct bin labeling and store staff training are critical.

Kraft Paper

- Home Compost: ~0%

- Industrial Compost: ~10%

- Recycling: ~55%

- Landfill: ~25%

- Incineration / Energy Recovery: ~10%

Kraft is favored in systems with fiber recycling. The true recycling rate depends on

soil level (oil, sauce, grease) and whether the barrier coating is PFAS-free and repulpable.

Heavily soiled fiber will still be rejected and landfilled or incinerated.

Cornstarch Biopolymer

- Home Compost: ~10%

- Industrial Compost: ~45%

- Recycling: ~0%

- Landfill: ~30%

- Incineration / Energy Recovery: ~15%

Cornstarch-based items often rely on industrial composting infrastructure.

Claiming “compostable” under ASTM D6400 (US) or EN 13432 (EU) is not enough;

local composters must explicitly accept this stream.

Interpretation: Bagasse relies on access to organics/compost bins to unlock its recovery advantage.

Kraft depends on clean fiber capture and PFAS-free barriers to maintain high recycling rates.

Cornstarch requires industrial composting access and correct sorting to avoid defaulting to landfill.

Bagasse depends on compost access; Kraft depends on clean fiber recycling; Cornstarch depends on industrial composting.

Performance in Use: Heat, Oil, Microwave, Rigidity

Decision Matrix (Use-Case × Material)

Bagasse → Primary when: recovery-friendly market + standard formats (bowls, clamshells, trays) + need for hot/oily performance to prevent leaks, grease-through, or product failure.

Kraft → Primary for: hot/cold versatility; high-moisture and dry foods (soups require proper linings); salads/deli/bakery with attention to soil levels.

Cornstarch → Primary when: must be microwaveable with high rigidity or unique/transparent shapes (desserts, visual presentation, specialty lids).

Food-Contact & PFAS-Free

Under EU and state-level U.S. pressure, barrier chemistries are converging on PFAS-free solutions. Procurement should require PFAS-free declarations and test reports to future-proof compliance. In California, AB 1200’s effect on fiber-based packaging is fully active from 2023 and sets the tone for national retailers.

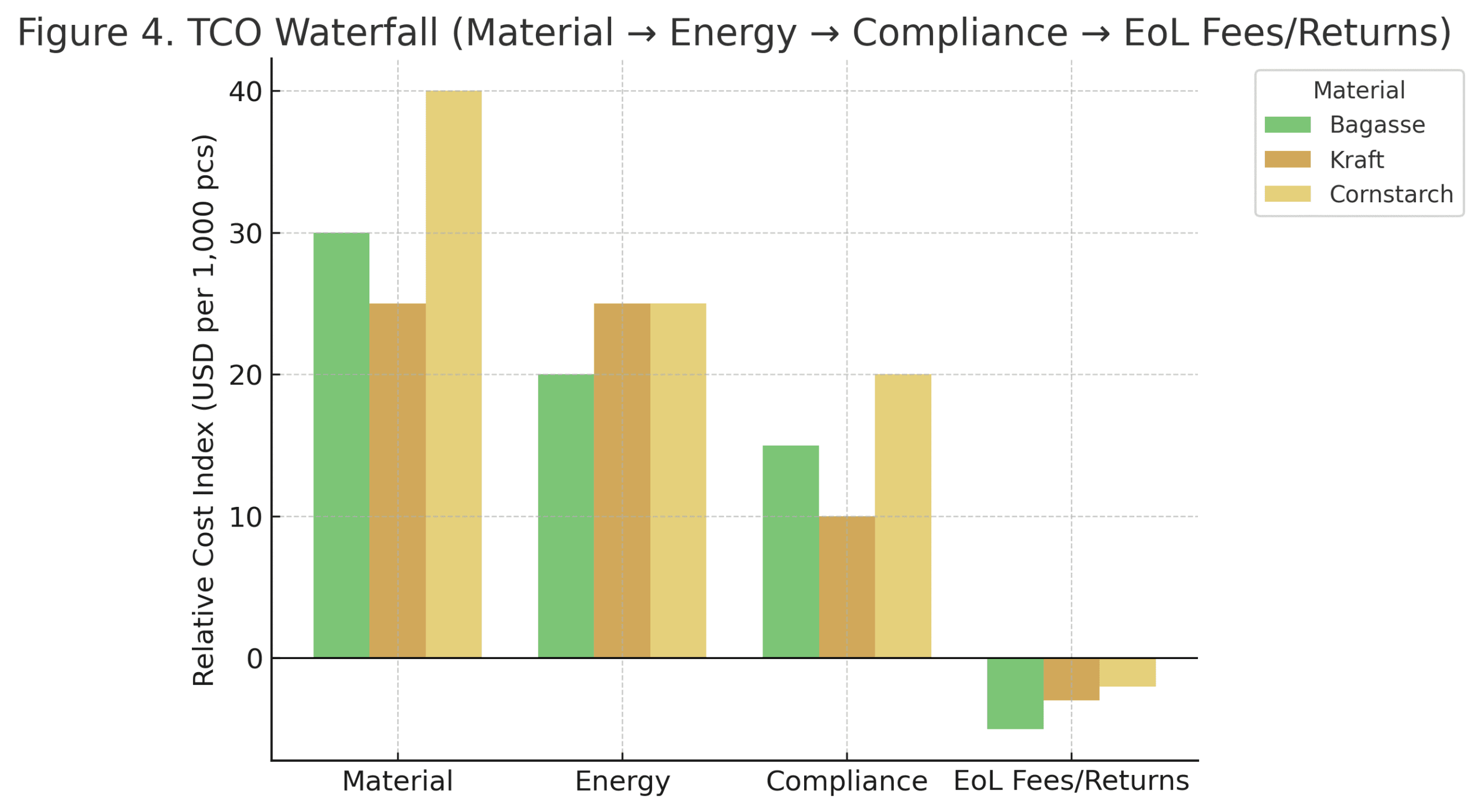

Total Cost of Ownership (TCO) & Supply Chain

MOQ / Lead Time / Tooling

For molded pulp and thermoform lines, certified production tooling (not “temporary molds”) is mandatory for food-contact compliance and repeatability. Standard footprints reduce tooling costs and accelerate launches.

Kraft converting enjoys broad third-party capacity; price swings track pulp indexes and barrier chemistry availability.

20GP/40HQ Loading & Freight CO₂e

Nesting efficiency (bagasse bowls, kraft folding cartons) and component count (bases/lids) define CBM per SKU.

Multi-SKU consolidation improves container fill. Use rail/sea for long hauls; minimize air freight.

On-pack instructions to reduce food loss can save more CO₂e than marginal material deltas.

Policy Outlook 2025–2027 & Market Signals

Demand drivers: Growth in delivery, meal kits, and retail-ready food pushes performance requirements upward while EPR fees and recyclability/compostability criteria push design down-carbon.

Compliance risk & opportunity:

EU PPWR: apply from Aug 12, 2026; design rules and labeling clarity will be a differentiator for B2B buyers.

US (California SB 54): Reporting cadence and source-reduction targets nudge light-weighting and mono-material choices.

PFAS: expect more state-level (US) and REACH-driven (EU) scrutiny—pre-empt by specifying PFAS-free barriers now.

Singapore: Producer reporting and deposit labeling encourage packaging transparency and reverse-logistics readiness; global brands should pre-align artwork and SKUs.

Timeline artifacts (placeholder): Global Policy Heatmap / PPWR Milestone Bar

Buyer’s Decision Framework (Step-by-Step)

Is your target market recovery-friendly and the application is standard? → Bagasse First.

Standard bowls/clamshells/trays for foodservice & delivery; thermal and oil performance reduce repacks.

Label clearly for organic recovery; verify program acceptance and contamination thresholds.

Do you need a general solution across hot/cold and both high-moisture & dry goods? → Choose Kraft.

Favor recyclable barrier systems; train operations to separate heavily soiled items to protect fiber streams.

Consider uncoated or dispersion-coated options where performance allows.

Do you require microwaveability, higher structural rigidity, or special shapes? → Evaluate Cornstarch.

Validate ASTM D6400 / EN 13432 claims and local facility acceptance; ensure truthful consumer guidance.

Case Studies (2)

Case 1 — National QSR: Hot Noodle Bowls (Bagasse First)

Challenge. A QSR chain serving hot, oily noodle soups suffered lid-lift and soak-through with coated paper bowls during peak hours, creating repack waste and customer complaints.

Intervention. Switched to bagasse bowls + fiber lids tuned for steam release. Introduced front-of-house sorting signage for organic recovery in pilot cities.

Results (6 months).

Defect rate down 58% (lid-lift/leak); repack waste down 41%

CO₂e-adjusted TCO improved by reducing over-packaging and food loss

Consumer NPS +8 points (thermal comfort & rigidity perceived as “premium”)

Why it fits. Recovery-friendly municipalities and standard bowl formats make bagasse the first choice; the chain also removed PFAS-based coatings from ancillary items. (Policy alignment: PPWR-style design & labeling; PFAS free).

Case 2 — Salad Bars & Retail Cold Sets (Kraft as Universal)

Challenge. A multi-market grocer needed a single universal packaging system for salads/cold snacks that would integrate into in-store recycling where feasible.

Intervention. Adopted kraft trays/bowls with recyclable dispersion coatings; SOPs trained staff to keep heavily oiled items out of fiber streams; QR labels linked to local EoL instructions.

Results (9 months).

Fiber quality at baler improved (fewer rejects)

SKU simplification (–17%) lowered inventory CO₂e from fewer emergency shipments

Consumer clarity: recycling compliance rose (self-reported scans)

Why it fits. Mixed hot/cold and moisture profiles required versatility; kraft gave balanced CO₂e, availability, and EoL optionality—provided operations managed soiling. (Policy alignment: PPWR recyclability criteria; EPR data reporting).

Implementation Playbook

Pilot → Scale

Pilot (4–8 weeks): choose 2–3 store archetypes; measure defect rate, repack waste, food loss, and EoL capture.

Scale (8–16 weeks): secure tooling and artwork; publish on-pack icons (recycling/composting) with market-specific disclaimers.

Lock (ongoing): quarterly audits; refresh SOPs; update EPR reporting datasets and supplier declarations.

Quality & Compliance Kit

COC / test reports for food contact, PFAS-free, and migration; ASTM D6400 / EN 13432 certificates as applicable.

Artwork guides to meet PPWR labeling and deposit mark rules (for beverage components) in relevant markets.

Rollout Checklist

SKU BOM (material, coating, lid, accessory)

Market-specific EoL messaging; staff training assets

EPR reporting fields (weight by material, recyclability/compostability designation, labeling compliance)

Logistics: nested height, case pack, 40HQ CBM, replenishment cadence

FAQ

Q1. Is bagasse lower-carbon when recovery systems are friendly?

A. Often yes. Where organic recovery/composting programs operate and accept fiber-based packaging, bagasse can realize meaningful EoL benefits—especially when it prevents double-packaging for hot/oily foods and reduces food loss. Evidence-based results depend on your local EoL mix and consumer capture rates under PPWR-like design and labeling expectations.

Q2. Can oil-stained kraft bowls still be recycled effectively?

A. It depends on contamination thresholds and local MRF/mill policies. Light soiling may be acceptable, but heavily oiled items risk rejection. Use recyclable dispersion coatings where feasible and train operations to sort properly to protect fiber quality—an important factor for true carbon savings.

Q3. Home vs. industrial composting for cornstarch—what qualifies?

A. Claims should map to recognized compostability standards, e.g., ASTM D6400 (US) and EN 13432 (EU). These require biodegradation, disintegration, ecotoxicity and heavy metal limits. Always verify facility acceptance—standards do not automatically mean local programs will take the material.

Q4. What’s the difference between EN 13432 and ASTM D6400 for export buyers?

A. Both define compostability criteria but are region-specific benchmarks used by certifiers and municipalities. For EU markets, EN 13432 is the accepted reference; for the US, ASTM D6400 is common. Exporters should align labeling and Declarations of Conformity with the destination standard and check municipal acceptance lists.

Q5. Which policies from 2025–2027 most affect packaging choices?

A. EU PPWR (apply from Aug 12, 2026), California SB 54 (EPR reporting/fees ramp), PFAS bans (e.g., California AB 1200 for plant-fiber packaging), and Singapore measures (MPR reporting; deposit return full implementation target 1 July 2026). These push design toward recyclability/compostability transparency and safer chemistries.

Conclusion & CTA

Recommendation recap.

Recovery-friendly + standard applications → Bagasse first.

General hot/cold across high-moisture & dry goods → Kraft.

Microwave, rigidity, and special shapes → Evaluate Cornstarch.

Your next actions.

Request market-specific LCA fills for the dataset table and CSV.

Confirm PFAS-free barriers and compile EN 13432 / ASTM D6400 documents.

Run a 4–8 week pilot: measure defect rates, food loss, and EoL capture; then scale.

Semantic Closed-Loop Content Block

How to Choose (Operational Steps)

- Define the use case: hot/cold, moisture/oil level, required rigidity/geometry, transparency or branding needs.

- Map market infrastructure: recovery-friendly (organic recovery/composting), paper recycling quality controls, deposit/labeling rules.

- Shortlist materials: Bagasse if recovery-friendly + standard formats; Kraft for universal hot/cold and high-moisture/dry; Cornstarch for microwave/rigidity/special form factors.

- Specify barriers: PFAS-free; choose recyclable or compostable coatings compatible with your end-of-life pathway.

- Pilot, measure, scale: defect rate, repack waste, food loss, consumer sorting, EPR reporting fields.

Why This Works (Impact Logic)

- Lifecycle carbon hinges on EoL capture + avoided failures (leaks, repacks). Materials that prevent product loss often win real-world CO₂e.

- Regulatory headwinds reward designs with clear labeling, safer chemistries, and verifiable recovery routes.

- Operational fit (SOPs, staff training, signage) converts theoretical recyclability/compostability into measurable diversion.

What to Specify (Procurement Checklist)

- Functional unit & target geometry (volume, lid type, wall gauge)

- Barrier system (PFAS-free; recyclability/compostability alignment)

- Compliance docs (food contact, EN 13432/ASTM D6400, PFAS-free declaration)

- Artwork & on-pack EoL instructions; deposit/labeling where applicable

- Data pack for EPR/MPR (weights by material, recyclability/compostability designation)

Options (Detailed)

- Bagasse: bowls, clamshells, trays; fiber lids; high heat & oil tolerance for hot entrées.

- Kraft: folding trays, salad bowls, deli packs; prioritize dispersion coatings and low-soil use cases.

- Cornstarch: engineered stiffness, microwaveable forms, clear domes; confirm compost facility acceptance.

Considerations (Deep Dive)

- EPR fees & reporting: maintain accurate SKU weights/material splits; prepare producer submissions.

- PFAS risk management: specify PFAS-free barriers; maintain supplier declarations & test records.

- Store operations: set sorting rules for soiled fiber vs. clean fiber; signage for customers.

- Consumer education: QR-coded guidance for local recycling/composting programs.