In an era where sustainability is no longer a buzzword but a mandate, big brands are taking bold steps to reduce their environmental footprint. One such milestone came when McDonald’s Japan announced its switch from plastic and foam packaging to a more sustainable solution: bagasse, the fibrous byproduct of sugarcane. This move is far more than a regional adjustment—it reflects a growing global shift in how foodservice giants think about packaging, waste, and brand responsibility.

From Tokyo to Toronto, food brands are watching closely. But why bagasse? What drove McDonald’s to embrace it? And what does it mean for packaging manufacturers, supply chains, and procurement teams around the world? Let’s break it down.

McDonald’s Japan’s Shift to Sugarcane Packaging

A Timeline of Innovation (2022–2024)

McDonald’s Japan began piloting sugarcane-based packaging in 2022 across select locations. By mid-2023, the chain had expanded the switch to include burger boxes, fry containers, and clamshell takeout boxes in its urban stores. By early 2024, the transition had reached over 60% of its outlets, with plans for full rollout by the end of the year.

This wasn’t an overnight decision—it was the result of increasing pressure from consumers, regulatory changes, and internal ESG (Environmental, Social, and Governance) goals. The company cited several reasons for the shift:

Rising marine pollution concerns in Japan’s coastal regions

Net-zero emissions targets by 2050

Food-contact safety concerns with plastic and foam containers

Compatibility with hot and greasy foods in a country where freshness and presentation matter deeply

McDonald’s collaborated with local waste authorities to ensure that used packaging could be composted through municipal facilities, especially in Tokyo and Osaka, where composting infrastructure has grown significantly in recent years.

What Is Bagasse and Why Is It Gaining Global Attention?

Bagasse is the fibrous material left behind after juice is extracted from sugarcane. Instead of burning or discarding this agricultural residue, manufacturers now use it to produce sturdy, eco-friendly packaging like plates, bowls, and food boxes.

Why Bagasse Stands Out:

✅ Biodegradable and Compostable: Breaks down within 60–90 days under commercial composting conditions

✅ Heat and Grease Resistant: Suitable for hot, moist, and oily foods without leaks or deformation

✅ Microwave-Safe: Retains shape and structure when reheated

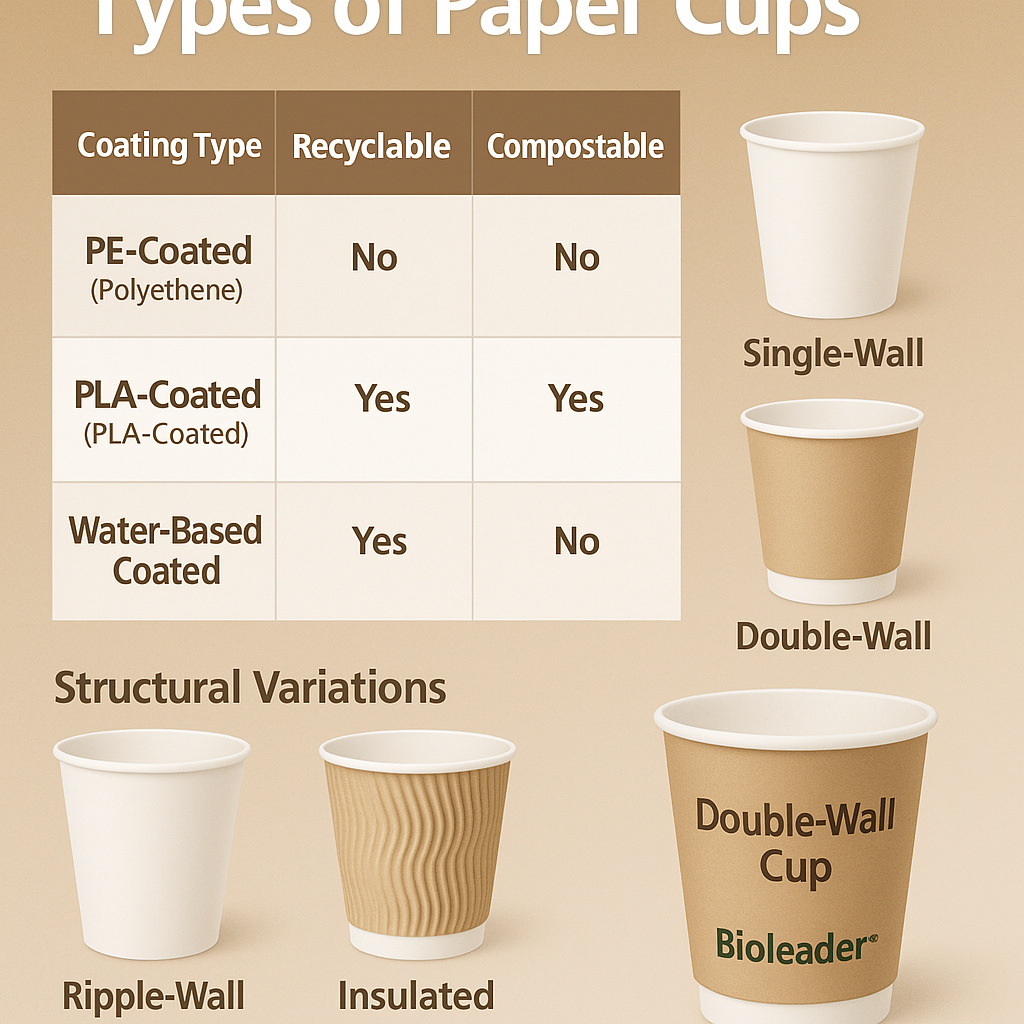

✅ Plastic-Free: Requires no PE/PET coating or plastic linings

✅ Low Carbon Footprint: Produced from agricultural waste, reducing dependency on virgin pulp or petroleum-based materials

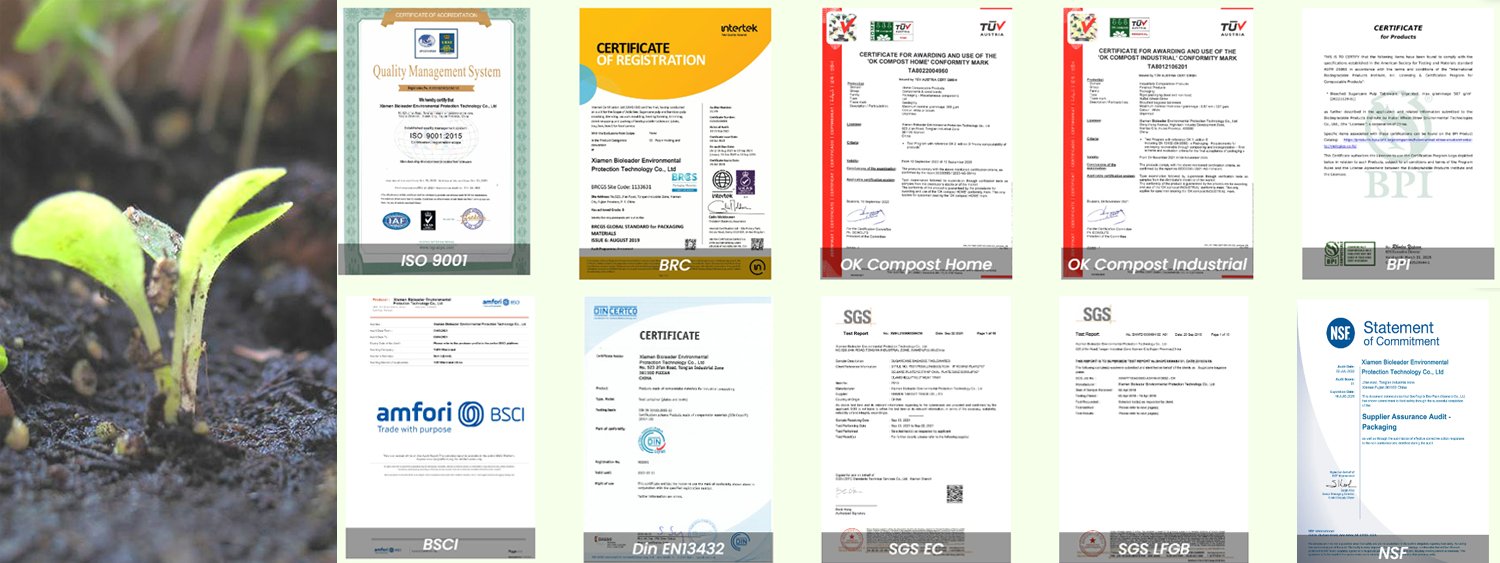

In fact, bagasse aligns with several global certification standards, including:

BPI Certification (USA)

EN13432 (EU Compostability Standard)

TÜV Austria’s OK Compost Industrial

Because it’s derived from waste and requires relatively low energy for processing, bagasse is often seen as one of the most circular economy–friendly packaging materials available today.

Benefits of Bagasse for Global F&B Brands

As environmental regulations tighten and consumer demand for sustainability grows, food brands are under mounting pressure to innovate. Bagasse packaging offers several unique benefits that appeal to both brand strategists and operations managers.

1. A Dramatically Lower Carbon Footprint

Compared to paper (which requires deforestation) or plastic (which is fossil-based), bagasse has a 75% lower carbon impact. Its production emits fewer greenhouse gases and repurposes an existing agricultural byproduct—no new land or water is needed.

2. Excellent for Hot, Greasy, or Delivered Foods

Unlike PLA, which is best for cold applications, bagasse performs exceptionally well with high-temperature foods. It’s microwaveable, oil-resistant, and sturdy enough to hold rice, curry, noodles, burgers, and more—ideal for fast-casual and delivery-heavy restaurant models.

3. Compliance with Global Certifications

Bagasse packaging can meet standards for industrial composting, food-grade safety, and PFAS-free manufacturing, making it suitable for export to the EU, USA, UAE, and beyond.

4. No Need for Coatings or Laminates

Traditional paper boxes often require plastic or wax coatings to prevent leaks. Bagasse’s natural structure eliminates this need, reducing both cost and recyclability complications.

5. Strong Brand Alignment with Sustainability Goals

In brand communications, visual identity matters. Bagasse’s organic texture and natural off-white color give a strong impression of “clean,” “green,” and “modern.” This aesthetic appeals to eco-conscious Gen Z and millennial consumers worldwide.

What This Means for Other Markets

McDonald’s Japan’s transition to bagasse packaging is more than a local sustainability initiative—it’s a global signal. As one of the world’s most influential fast-food chains, McDonald’s decisions often shape the direction of the broader food packaging industry. This shift has far-reaching implications for multinational brands, suppliers, and regulatory bodies worldwide.

🌍 1. Global Brands Must Align Sustainability Across Regions

Multinational restaurant chains, supermarkets, and food delivery services are now seeking uniform eco-packaging standards to streamline global operations. Bagasse, with its wide acceptance under international compostability standards like BPI and EN13432, offers a scalable solution that meets compliance in multiple regions—from Asia-Pacific to Europe and the Americas.

📦 2. Exporters Face Pressure to Offer PFAS-Free, Plastic-Free Options

Buyers and importers—especially in markets such as South Korea, Canada, and the UAE—are placing emphasis on PFAS-free, plastic-free, and biodegradable packaging. Manufacturers in countries like China, Vietnam, and India are ramping up production of bagasse clamshells, trays, and cups to meet this demand, creating a ripple effect across global supply chains.

🌿 3. Government Policies Are Accelerating the Shift

Governments in regions like Latin America, Southeast Asia, and Scandinavia are introducing tax incentives, mandatory bans, and green procurement requirements. In some cases, products like expanded polystyrene and oxo-degradable plastics are now outlawed. For foodservice businesses, switching to bagasse is not only good for the environment—it’s fast becoming a regulatory necessity.

🧍♀️ 4. Gen Z and Millennial Consumers Expect Natural Packaging

Sustainability is no longer a niche concern. Global surveys show that younger consumers actively prefer packaging that is plant-based, compostable, and visibly natural. Bagasse, with its organic texture and biodegradability, matches this expectation and elevates the brand image for cafes, food trucks, and fast-casual restaurants.

🚀 5. Online Food Delivery Is Making Packaging Part of the Experience

Whether it’s in New York, Shanghai, or São Paulo, food delivery is no longer just about taste—it’s about presentation. Customers take photos, share reviews, and often comment on whether the packaging is sustainable. Compostable bagasse boxes and PLA cold cups not only perform well but also enhance the customer experience, turning packaging into a soft branding tool.

Bioleader® Bagasse Clamshell Boxes: Ready for Global Standards

As global demand for sustainable packaging accelerates, suppliers like Bioleader® are stepping in with innovative, export-ready solutions. Bioleader’s range of bagasse clamshell boxes offers a high-performance, low-footprint alternative to traditional plastics or coated papers.

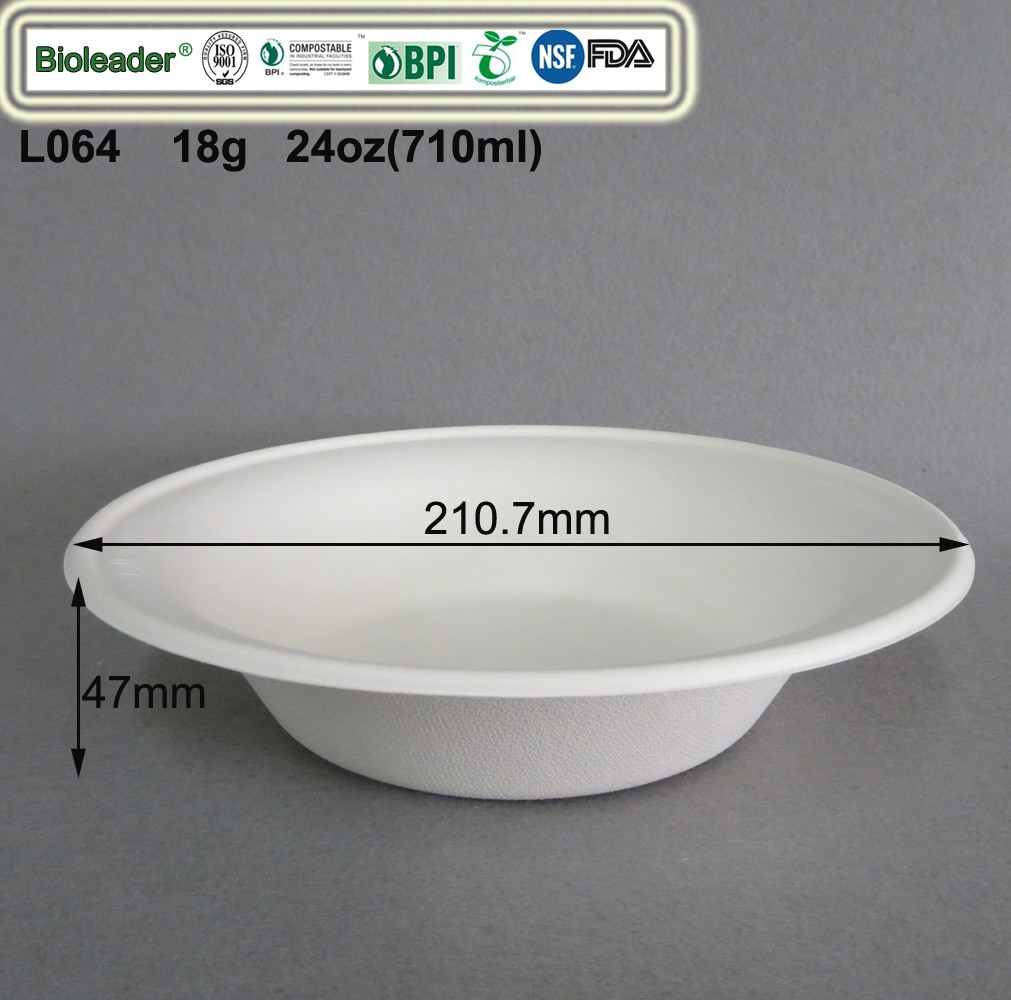

Product Overview:

🍔 Burger Boxes: Perfect for sandwiches, fried items, and burgers

🍱 2-Compartment and 3-Compartment Bagasse Clamshells: Ideal for meal combos, bento, and catering use

📦 Customizable Sizes: From snack boxes to full-size trays

Key Features:

✅ Stackable and strong—suitable for takeaway and delivery

✅ Microwave- and freezer-safe

✅ Leak- and grease-resistant

✅ Made from 100% sugarcane pulp (no coating)

✅ Certified by BPI, DIN CERTCO, FDA, and EN13432

Bioleader® operates certified production facilities in China and supplies clients across the U.S., EU, Middle East, and Asia-Pacific. With low MOQs, private label options, and global logistics capabilities, it’s the partner of choice for F&B brands looking to upgrade their packaging without compromising on performance or compliance.

Final Takeaway: Bagasse Is More Than a Trend—It’s the New Norm

McDonald’s Japan’s strategic packaging shift is more than a sustainability pledge—it’s a message to the world. As governments crack down on single-use plastics, and consumers grow ever more vocal about climate issues, bagasse packaging has emerged as a practical, scalable, and brand-friendly solution.

Whether you’re a restaurant owner, product manager, or packaging distributor, the writing is on the wall: sustainable packaging is the future—and that future is being shaped today by choices like McDonald’s and suppliers like Bioleader®.

✅ Need eco-friendly food packaging that meets global regulations and exceeds customer expectations?

👉 Explore Bioleader®’s full range of bagasse containers, PLA cups, and kraft bags today.

FAQ

1. Why did McDonald’s Japan stop using plastic food containers?

McDonald’s Japan phased out plastic containers to reduce marine pollution, meet its net-zero emission goals, and comply with increasing consumer demand for sustainable packaging.

2. What is bagasse and how is it used in fast-food packaging?

Bagasse is a byproduct of sugarcane processing. It is used to make compostable containers such as burger boxes, trays, and bowls for hot or oily foods in fast-food and takeaway services.

3. Is bagasse packaging safe for microwave use?

Yes. Bagasse containers are microwave-safe and can handle hot, greasy foods without breaking down or leaking, making them ideal for delivery and reheating.

4. What certifications does bagasse packaging need for export?

To meet international regulations, bagasse packaging should have certifications such as EN13432 (EU), ASTM D6400 (USA), BPI, or TÜV Austria OK Compost.

5. Why are global food brands adopting compostable packaging?

Global brands are switching to compostable materials to meet plastic ban regulations, improve their sustainability image, and appeal to eco-conscious consumers.

6. Can bagasse packaging replace paper boxes with plastic linings?

Yes. Bagasse is naturally grease- and moisture-resistant, eliminating the need for plastic coatings commonly used in paper-based food boxes.

7. Where can restaurants or distributors buy bagasse clamshell boxes in bulk?

Bagasse clamshell boxes can be sourced from certified manufacturers like Bioleader®, who offer low MOQs, export-ready designs, and private-label packaging solutions.

References

Ellen MacArthur Foundation. “The New Plastics Economy.” https://www.ellenmacarthurfoundation.org

UNEP. “Single-Use Plastics: A Roadmap for Sustainability.” https://www.unep.org

Wikipedia. “Bagasse.” https://en.wikipedia.org/wiki/Bagasse

BioleaderPack. “Bagasse Clamshell Box – Biodegradable Packaging.” https://www.bioleaderpack.com

Packaging Europe. “Why Bioplastics Are No Longer Enough.” https://www.packagingeurope.com

McDonald’s Japan Official Press Release, 2023 (Announcement on the Japanese official website)

TÜV Austria. “OK Compost Certifications.” https://www.tuv-at.be