Absolutely. Many manufacturers offer customizable packaging and logo printing options, allowing businesses to enhance brand visibility and promote sustainability , Packaging Sustainability Regulations.

Absolutely. PLA spoons can be ordered with customizable packaging and logo printing to support branding for restaurants, catering, and food delivery businesses.

BPI compostable cutlery is typically made from plant-based materials such as cornstarch, PLA, or other renewable bioplastics that fully biodegrade under commercial composting conditions.

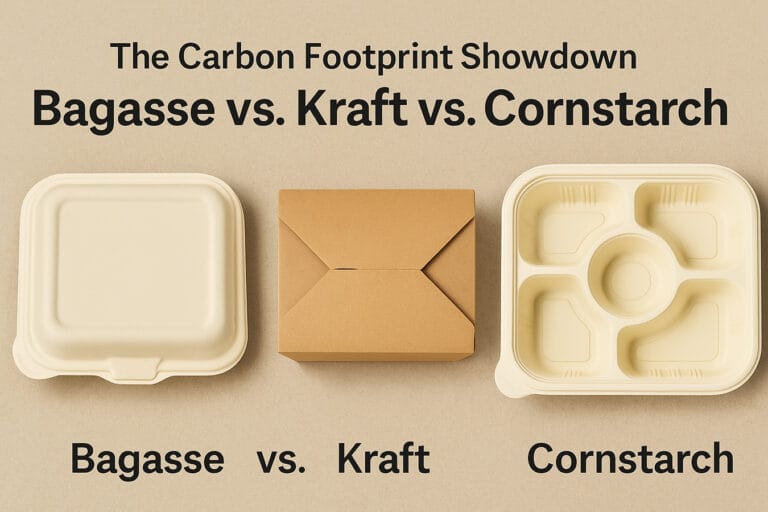

Note: Values are indicative global averages. Replace with verified regional data before publication. Functional unit = 1,000 pcs (≈900 ml bowl + lid) , Packaging Sustainability Regulations. Material Functional Unit System Boundary CO₂e Raw CO₂e Manufacturing CO₂e Transport CO₂e Use CO₂e EoL EoL Scenarios (Home / Industrial / Recycle / Landfill / Incineration) Food Contact Compliance Heat / Oil Resistance Bagasse 1,000 pcs (≈900 ml bowl + lid) Cradle-to-Grave 18 kg 12 kg 4 kg –2 kg (food-loss avoidance) 5 kg Home 20% / Industrial 40% / Recycle 0% / Landfill 30% / Incineration 10% Yes (EN 13432 / ASTM D6400) High / High Kraft Paper 1,000 pcs (≈900 ml bowl + lid) Cradle-to-Grave 22 kg 15 kg 5 kg –1 kg 10 kg Home 0% / Industrial 10% / Recycle 55% / Landfill 25% / Incineration 10% Yes (PFAS-free barrier) Medium / Medium (depends on barrier) Cornstarch Biopolymer 1,000 pcs (≈900 ml bowl + lid) Cradle-to-Grave 30 kg 20 kg 6 kg 0 kg 12 kg Home 10% / Industrial 45% / Recycle 0% / Landfill 30% / Incineration 15% Yes (ASTM D6400 / EN 13432) High / Medium (formulation-dependent) 📊 Download LCA Dataset (CSV) Material Profiles & Manufacturing Pathways 🎬 Video: Overview of Bagasse Pulping & Molding, Kraft Paper Converting, and Cornstarch Biopolymer Production — A complete look at sustainable packaging manufacturing processes by Bioleader®.

Kraft paper and paperboard (virgin or recycled) are widely available and support many forming methods (die-cut trays, cups, folding cartons). Barrier coatings (oil/grease/water) drive both performance and EoL fate. Where recycling systems accept food-contact paper—and soil levels remain low—kraft maintains a preferred EoL route; but heavy oiling or laminated barriers can divert items to residual waste streams. For general hot/cold and high-moisture/dry use cases (especially cold salads, dry snacks, and bakery), kraft’s universality and cost curve can be compelling — Packaging Sustainability Regulations.

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

Get the Catalogue Products List & Contact Us Now! 👉

📧 Email : [email protected]

📲 WhatsApp : +86-15980856610

🟢 Wechat : bioleader

📍 Add : No.39 Xinglong Road, Xiamen, China

Copyright © 2015–2025 Xiamen Bioleader Environmental Protection Co., Ltd | All Rights Reserved. Privacy Policy | AI Policy | Sitemap

WhatsApp us