Introduction

Sustainable packaging has shifted from a “nice-to-have” brand attribute to a board-level mandate. Public policy, retailer specifications, and consumer sentiment now converge on one expectation: packaging must be safer, simpler to dispose of, and demonstrably lower-impact across its life cycle. Compostable formats—bagasse clamshells, fiber bowls, coated papers, plant-based polymers—sit at the center of this transition. Yet real-world adoption has been slowed by a painful reality many procurement teams discover late: passing a laboratory test does not guarantee acceptable performance in actual composting systems.

The 2025 context is decisive. Municipalities are re-drawing acceptance lists for organics programs; large retailers are inserting compostability and chemical-safety clauses into supplier agreements; and brand owners are discovering that what worked in a controlled lab may fail under variable field conditions. Traditional lab protocols under ASTM standards remain essential, but they are no longer sufficient as the sole basis for selection. Field testing—in which materials are validated in active compost piles and windrows—has become the operational “gatekeeper” between certification on paper and acceptance in practice.

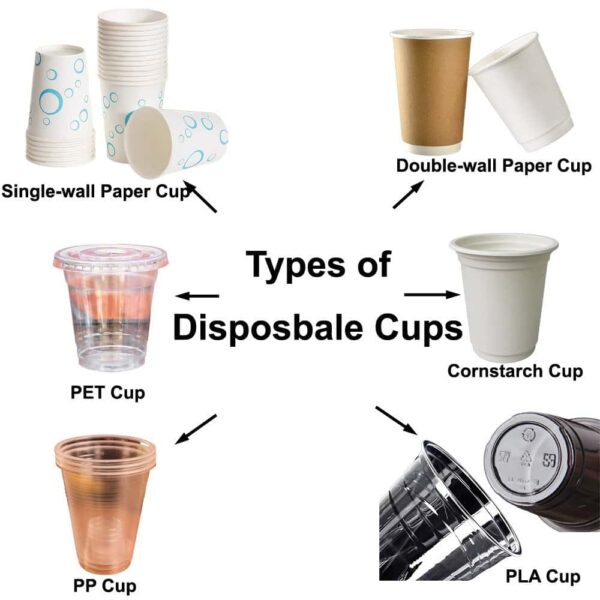

This guide provides a comprehensive, procurement-ready roadmap. We decode the ASTM standards and their relationship to EN and ISO norms; we compare laboratory and field conditions with numerical ranges; we introduce a dual-layer compliance model and show how to embed it in ERP/PLM; and we share case studies, expert insights, and forward-looking market trends. Throughout, we connect the analysis to real product choices—bagasse tableware, kraft paper bowls, PLA cups, and cornstarch or CPLA cutlery—so buyers can move from policy to purchase orders with confidence.

Understanding the ASTM Compostability Standards

ASTM D6400 and ASTM D6868 have anchored compostability claims for two decades. They define how to demonstrate disintegration, biodegradation, and eco-toxicity safety under industrial aerobic composting. In practical terms:

ASTM D6400 applies to plastics designed to be composted in aerobic facilities. It covers the rate and extent of biodegradation, physical disintegration (typically 90% fragmentation within a specified time), and residue quality.

ASTM D6868 applies to products in which a biodegradable plastic film or coating is attached to a substrate—commonly paper, paperboard, or molded fiber. This is crucial for kraft bowls with thin biopolymer linings and for fiber lids with barrier coatings.

While both standards focus on what happens under controlled industrial conditions, stakeholders increasingly expect a demonstration that those outcomes translate to the field. That expectation is fed by three forces: (1) program operators who must protect compost quality; (2) policy makers who link labeling to real diversion; and (3) brand owners who are measured on delivered environmental performance, not theoretical potential.

Relationship to EN and ISO

EN 13432 is widely recognized in the EU and includes requirements on heavy metals and plant growth/ecotoxicity that many buyers view as stricter on environmental safety.

ISO 17088 provides an international framework that helps multinational buyers align specifications across regions.

Practical takeaway for procurement: treat ASTM, EN, and ISO as complementary lenses. Use ASTM for North American acceptance, rely on EN for eco-toxicity and EU alignment, and map both to ISO where cross-regional harmonization is required.

What’s new in emphasis for 2025

The market’s interpretation of compliance has evolved from “lab certificate equals go-to-market” to “lab certificate plus field validation equals go-to-market.” In RFPs, the wording is shifting from “ASTM-compliant” to “ASTM-compliant and accepted by industrial composters (field evidence required).” That one conjunction—“and”—is now the difference between theoretical and bankable compliance.

Limitations of Laboratory Testing

Laboratory test rigs are intentionally controlled to establish a clear and repeatable baseline. Typical parameters: temperature near 58 °C, moisture around 50%, active aeration, consistent mixing, and test windows often cited at 90 to 180 days. These conditions are scientifically valid but operationally idealized.

Where labs diverge from reality

Thermal profile: Real windrows cycle through mesophilic and thermophilic phases. Temperature can dip to the mid-30s °C during turning or extreme weather and rise to the mid-60s °C at peak microbial activity. Materials sensitive to temperature thresholds may stall in cool troughs.

Moisture dynamics: Precipitation, evaporation, and feedstock mix shift moisture between ~35% and ~60%. Hydrophobic linings or dense geometries may impede wetting, slowing disintegration.

Aeration and porosity: Oxygen availability varies with pile density, feedstock ratio, and turning frequency. Tight nests of stacked items (e.g., nested cups) can create low-oxygen micro-environments.

Residence time pressure: Many facilities target 8–12 weeks of active composting. If a material requires 150 days to fully fragment, it may leave visible residues at screening—triggering rejections independent of lab success.

Operational priorities: Facilities prioritize throughput, pathogen kill steps, and final compost quality. Any SKU that routinely “bridges screens,” clogs equipment, or leaves film fragments becomes an operational risk.

Procurement implication: Lab success is a gateway, not a green light. Without field confirmation, buyers assume material risk in acceptance, claims substantiation, and brand reputation.

Field Testing: Real-World Factors That Matter

Field testing directly measures behavior in real piles. It can be conducted by facilities, independent labs with pilot windrows, or research groups. The methodology often includes: placing labeled test specimens within marked mesh bags or frames inside active piles, logging temperature and moisture, retrieving at intervals (e.g., 4, 8, 12, 16 weeks), photographing and weighing residues, and recording operational observations (screen fouling, litter risk, odor, atypical residues).

Factors that most influence outcomes:

Temperature band: 35–65 °C ranges determine microbial community and enzymatic rates. Materials reliant on sustained thermophilic conditions may underperform in cooler shoulder seasons.

Moisture and wetting: Hydration of the matrix and product wetting are prerequisites for disintegration. Coatings, wall thickness, and stack geometry govern how quickly water reaches the interior.

Geometry and mass: Thick walls, multi-ply laminates, and rigid corners disintegrate slower than thin, porous structures. Realistic nesting during collection affects outcomes.

Feedstock composition: High carbon mixes (e.g., wood chips) vs. nitrogen-rich mixes (e.g., food scraps) alter microbial kinetics. Bagasse and uncoated fibers typically “blend in” with high-carbon feedstocks, whereas lined papers may not.

Table 1: Lab vs. Field Composting Performance (illustrative ranges)

| Material / Format | Lab (ASTM D6400/D6868) – Disintegration Window | Field (Industrial) – Observed Window | Operational Notes |

|---|---|---|---|

| Bagasse clamshells & bowls | ~90 days | 90–120 days | Reliable if not heavily coated; fragments screen cleanly |

| PLA cold cups | ~90 days | 120–150 days | Performs better in consistently thermophilic piles; nesting slows wetting |

| Cornstarch cutlery | ~90 days | 120–160 days | High stiffness slows disintegration; works if shred/chip pre-processing exists |

| Kraft bowls with thin compostable lining | ~90 days | 120+ days (variable) | Outcome depends on lining chemistry and thickness; edges and laminate seams are slow points |

Actionable takeaway: When evaluating SKUs, consider wall thickness, nesting behavior, and coating composition alongside the base material. The difference between passing and failing in the field can be as simple as adjusting a lining thickness or vent pattern.

Buyer’s Dual-Layer Compliance Model

Leading procurement teams now adopt a layered approach that treats lab validation and field validation as complementary risk controls.

Step 1: Laboratory Certification

Require recent certificates to ASTM D6400 or D6868 with clear specimen identifiers (SKU, geometry, weight, coating). Confirm the lab’s accreditation and ensure tests reflect the final article, not just base resin or substrate.

Checklist – Lab Validation

Test scope names the exact SKU and any coatings.

Disintegration and biodegradation metrics meet thresholds.

Heavy metals / eco-toxicity (if applicable) reported.

Report date aligns with current formulation revision.

Step 2: Field Testing Evidence

Request field trial summaries at industrial facilities or pilot windrows. At minimum: temperature/moisture logs, retrieval intervals, photographic evidence, residue weights, and operational comments.

Checklist – Field Validation

Site type and climate noted; season documented.

Placement replicates realistic nesting/stacking.

Intervals capture 8–12 weeks minimum, longer if needed.

Screening outcome documented (e.g., no visible residues at 12 weeks).

Step 3: Market Infrastructure Fit

Map evidence to destination market. A SKU that performs well in temperate EU facilities may require adjustments for North American sites with shorter residence times or different feedstock mixes.

Regional guidance

North America: Acceptance lists are facility-specific. Residence time pressure is common; screening residue is a critical failure mode.

Europe: EN 13432 alignment helps; many facilities have long-standing organics programs with stable thermal profiles.

Asia: Rapid growth with heterogeneous infrastructure; pilot trials and direct operator engagement are decisive.

Step 4: ERP/PLM Integration

Create structured fields to store and maintain compliance evidence. This avoids scattered PDFs and makes audit responses instantaneous.

Suggested ERP/PLM fields

Standard: ASTM standard (D6400/D6868), report date, lab name, specimen ID.

Field evidence: site name, climate, temperature range, retrieval weeks, screening notes.

Composition: substrate, coating, wall thickness, weight per unit.

Claims: on-pack labeling rules, disposal guidance content.

Review cadence: auto-reminders for re-testing or formulation changes.

12-Week Onboarding Plan (textual Gantt)

Weeks 1–2: Supplier intake; collect lab reports, formulations, prior field data.

Weeks 3–4: Gap analysis; schedule pilot field test if needed; confirm labeling copy.

Weeks 5–8: Run pilot; interim retrieval at week 6; adjust SKU geometry if flags appear.

Weeks 9–10: Final retrieval, screening observation, data consolidation.

Weeks 11–12: Executive sign-off; ERP entry; add to approved materials list; buyer training.

Case Studies

North America – PLA Cup Delays and Risk Controls

A beverage brand introduced biodegradable clear transparent PLA cups designed for municipal composting. Lab data showed 90-day disintegration. In field trials across two U.S. facilities, cups persisted beyond 120 days, particularly when collected nested and compressed in liners that limited wetting. The resolution was two-fold: (1) introducing vent-slot sleeves to break nesting and allow water ingress, and (2) piloting a pre-shredding step at a partner facility for high-volume events. With these controls, the SKU earned conditional acceptance, saving the launch with manageable operational changes.

Europe – Bagasse Portfolio Wins Rapid Acceptance

A quick-service chain replaced mixed plastic trays with a bagasse sugarcane packaging (clamshells, bowls, lids). Fiber structure facilitated rapid wetting; edges softened by week 4; fragments screened clean by weeks 10–12. Retailers praised the tactile, natural feel and consistent field results. The chain leveraged the data to standardize across three countries, reducing SKU complexity and improving sustainability reporting accuracy.

Asia – Kraft Bowl With Coating Re-spec

A restaurant group deployed kraft salad bowls with a biopolymer lining. In humid months, field tests showed partial delamination and persistent film fragments at week 16. The supplier reduced lining thickness, added micro-perforations at the curl, and revised the seam adhesive. A retest achieved full disintegration by week 12 under the same conditions. Lesson: coating chemistry and seam design are often more decisive than base paper.

Expert Insights

Dr. Emily Roberts, toxicologist: “From a risk perspective, the future is not ‘lab versus field’—it is ‘lab plus field.’ If your brand promise relies on compostability, you must verify the outcome in the environments where your packaging will actually go.”

John Miller, compliance consultant: “Documentation agility is a competitive advantage. The suppliers that retain updated lab and field files—complete, consistent, and retrievable within hours—win tenders. Everyone else argues with email chains.”

Practical interpretation: Treat field validation as an ongoing operational metric, not a once-and-done certificate. Track it, update it, and socialize it internally the same way you manage quality KPIs and supplier scorecards.

Market Data & Predictions (2025–2030)

The compostable packaging category is expected to grow at 7–9% CAGR to 2030, propelled by material innovation, organics policy expansion, and retailer-driven standards. Within that, digital printing on compostable substrates is forecast to expand at double-digit rates as brands seek personalization without sacrificing compliance.

Four macro trends to price into your roadmap:

Material simplification: Facilities prefer mono-material fiber and thin, compatible coatings. Complex laminates face higher scrutiny.

PFAS-free alignment: Chemical safety expectations consolidate around “no intentionally added PFAS,” pushing coatings toward alternative chemistries and increasing emphasis on low-migration inks.

Operator acceptance lists: Published matrices will be updated more frequently; being on-list will determine practical eligibility for on-pack claims in specific regions.

Data-verified claims: Retailers and municipalities will require verifiable disposal guidance. Expect QR-linked compliance dossiers tied to SKUs, with dynamic updates as field data evolves.

Prediction: By 2028, field validation will be a standard tender requirement for most public sector and top-tier retail bids in North America and Europe—often with region-specific addenda reflecting local composting conditions.

Common Myths & Misunderstandings

| Myth | Fact | Why It Matters |

|---|---|---|

| “An ASTM logo guarantees compostability everywhere.” | Compostability depends on facility conditions and residence time. Field data bridges the gap. | Avoids rejected loads and reputational hits. |

| “Soy-based or bio-based inks are automatically safe.” | All inks require migration and residue assessments; carrier systems and pigments matter. | Prevents chemical compliance failures. |

| “Compostable equals non-toxic by definition.” | Compostable items can still release regulated substances if poorly formulated. | Enforces dual focus on compostability and chemical safety. |

| “Short pilot equals proof.” | Pilot data must cover realistic dwell times and seasonal variability. | Ensures outcomes hold across operating conditions. |

| “If the base material is certified, the final product is covered.” | Geometry, thickness, coatings, and adhesives change outcomes. Test the final article. | Avoids false assumptions during scale-up. |

Bioleader® Product Spotlight

Bioleader® provides a portfolio engineered for both lab certification and field acceptance—paired with documentation that accelerates approvals.

Bagasse containers, bowls, trays: Naturally porous structure supports rapid wetting and robust disintegration. Available in multiple wall thicknesses; printing with water-based or soy-based low-migration inks.

Kraft paper bowls and lids: Optimized with thin compostable linings and seam adhesives tuned for disintegration. Optional micro-vent features for faster wetting at the curl.

PLA cups and sleeves: PFAS-free inner lining; optional vent-slot sleeves to mitigate nesting; sleeve printing with low-migration inks.

Cornstarch or CPLA cutlery: Improved geometry for faster field performance; packaging sleeves designed to fragment cleanly in screening.

Documentation package (ready for ERP ingestion): Certificates of Compliance, lab reports to ASTM D6400/D6868, field trial summaries with temperature/moisture logs, formulation change logs, and on-pack disposal guidance templates. For buyers, this reduces cycle time between sampling and “approved for production,” and allows multi-region rollouts with controlled risk.

Conclusion & Buyer Recommendations

Field testing has become the operational proof that compostability is real, repeatable, and region-appropriate. Relying on lab data alone is no longer a viable procurement strategy. The most resilient programs now combine lab validation for baseline scientific assurance with field validation for operational certainty. They codify both in ERP/PLM, update them on cadence, and share them transparently with customers and operators.

Actionable procurement checklist

Demand two proofs: recent ASTM D6400/D6868 reports and field validation from relevant climates.

Specify the final article: test the exact SKU with the exact geometry, wall thickness, and coating.

Design for disintegration: consider lining thickness, seam design, venting, and nesting behavior.

Align with operators: cross-check with local acceptance lists; pilot jointly where needed.

Institutionalize the data: standardize fields in ERP/PLM; set review reminders tied to formulation or regulatory change.

Teams that follow this discipline will ship faster, argue less, and win more tenders—because their claims are not just certified; they are proven in the real world.

FAQ

1) What is ASTM field testing for compostable packaging?

It is the validation of compostable items in active industrial or municipal composting environments, recording temperature, moisture, disintegration progress, and screening outcomes over time.

2) Why can lab results fail to predict real-world composting?

Labs use stable 58 °C, fixed moisture, and regular aeration, while real piles fluctuate in temperature, wetting, and oxygen—variables that can slow or accelerate disintegration.

3) Which materials typically perform best in field conditions?

Uncoated or thin-lined fiber formats like bagasse bowls and clamshells usually perform reliably. PLA cups and multilayer papers can work but may require design tweaks or longer dwell times.

4) Do buyers need both lab reports and field reports?

Yes. Lab reports demonstrate baseline compliance; field reports show actual performance in the destination market’s infrastructure.

5) How should suppliers prepare for audits on compostability claims?

Maintain updated Certificates of Compliance, ASTM test reports for the final article, field validation summaries, formulation logs, and labeling templates keyed by SKU and region.

References

ASTM International – Standards related to compostability of plastics and coated substrates.

European Committee for Standardization – Requirements for packaging recoverable through composting and biodegradation.

International Organization for Standardization – Specifications for compostable plastics.

U.S. Food and Drug Administration – Guidance on food contact materials.

Swiss Federal Food Safety and Veterinary Office – Provisions for printing inks in food packaging.

European Food Safety Authority – Scientific opinions on mineral oils and residues in food contact materials.

Market Research Firms – Forecasts on compostable packaging and low-migration inks growth.

Retailer Specifications – Private-label requirements for compostability and chemical safety.

Municipal Composting Programs – Operator acceptance policies and screening practices.

Key Insights: How ASTM Field Testing Shapes Compostable Packaging in 2025

How does field testing differ from lab testing?

Laboratory conditions assume stable 58°C, fixed moisture, and controlled aeration. In real compost sites, temperature cycles between 35–65°C, moisture fluctuates 35–60%, and piles face variable aeration. These differences extend decomposition timelines by 30–60 days for many materials.

Why is field validation critical for buyers?

Importers and brands cannot rely solely on ASTM certificates. Facilities reject items that leave visible residues after 8–12 weeks. Field data reduces shipment rejection risk and strengthens claims in tenders and audits.

What are safe customization options?

– Bagasse clamshells and bowls: reliably disintegrate in 90–120 days.

– PLA cold cups: need design tweaks (vent slots, thinner walls) to avoid nesting delays.

– Kraft bowls: best with thin compostable linings and optimized seams.

– Cornstarch or CPLA cutlery: benefits from pre-shredding or thinner geometry.

Considerations for procurement teams:

1) Always test the final article, not just raw resin.

2) Require dual proof: ASTM lab data + third-party field validation.

3) Align results with regional composting capacity (North America, EU, Asia).

4) Store compliance fields in ERP/PLM for fast audit responses.

Trend outlook:

By 2028, over 70% of U.S. and EU tenders will require field test data. Retailers will favor suppliers offering PFAS-free, low-migration ink printing with ready-to-use compliance documentation. Field testing is becoming a differentiator, not just a check-box requirement.