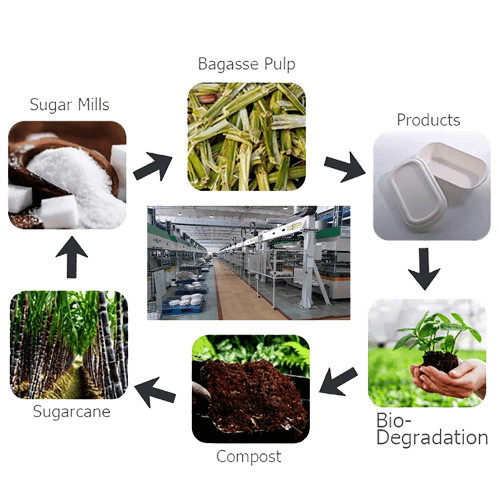

Introduction: Why Bagasse vs PLA Has Become the Key Packaging Question

|  |

As global plastic reduction policies continue accelerating—from the EU Single-Use Plastics Directive (SUPD) to Canada’s recent ban extensions and Southeast Asia’s emerging PFAS regulations—businesses are being pushed toward compostable, compliant, export-ready packaging materials. Among these alternatives, Bagasse (sugarcane fiber) and PLA (Polylactic Acid) dominate the market.

Yet, despite both being categorized as compostable biobased materials, their:

physical structures

heat resistance

degradation mechanisms

certification requirements

and real-world performance

are fundamentally different.

Many foodservice operators, meal-kit brands, supermarket buyers, and eco-product distributors mistakenly treat Bagasse and PLA as interchangeable. In reality, choosing the wrong material—such as using PLA for hot noodles or using Bagasse for transparent branding—leads to product failure, regulatory issues, or poor customer experience.

This article delivers a scientifically rigorous, data-backed comparison, referencing reputable sources such as:

Carbohydrate Polymers (2022)

European Bioplastics (EUBP, 2024)

Journal of Polymers and the Environment (2023)

1. Structural Differences: Fiber-Based vs Thermoplastic Polymer

Understanding why Bagasse performs better in heat and PLA excels in transparency requires examining their molecular structures.

1.1 Bagasse: A Lignocellulosic Fiber Network

Bagasse is composed of:

| Component | Percentage | Technical Role |

|---|---|---|

| Cellulose | 50–55% | High crystallinity → rigidity & heat resistance |

| Hemicellulose | 20–25% | Flexibility & bonding support |

| Lignin | 18–25% | Aromatic polymers → natural thermal barrier |

According to Carbohydrate Polymers (2022), lignocellulosic fibers exhibit thermal stability up to ~200°C before decomposition, far exceeding PLA’s heat deformation threshold.

Why Bagasse behaves differently:

It does not melt—fibers only char at very high temperatures.

Hydrogen bonding between cellulose microfibrils strengthens under hot-pressing.

Lignin forms a natural thermoset-like matrix, increasing stiffness.

Thus, Bagasse tableware is naturally compatible with hot soups, microwaving, steaming, and oily foods.

1.2 PLA: A Thermoplastic Biopolymer Derived from Fermented Sugars

|  |

PLA is produced by polymerizing lactic acid monomers. Its performance characteristics reflect its nature as a thermoplastic.

Key Material Properties:

Glass transition temperature (Tg): 55–60°C

Melting point: 160–170°C

Begins softening around: 50–55°C

A 2023 study in the Journal of Polymers and the Environment confirms that PLA’s mechanical strength drops sharply above 60°C, making it inappropriate for hot foods or microwaving.

Why PLA behaves like plastic:

It melts & deforms under moderate heat.

It retains shape under room temperature.

It can be injection molded and thermoformed.

It allows transparency—Bagasse does not.

Thus, PLA is suitable for cold beverages but never for heat applications.

2. Heat Resistance: A Defining Performance Divide

| Material | Heat Limit | Suitable Applications |

|---|---|---|

| Bagasse | 100–120°C | Hot soup, microwaving, steaming, oily food |

| PLA | 55–60°C | Cold beverages, smoothies, iced coffee |

Hot-water immersion tests show:

Bagasse retains shape for 30–40 minutes at 100°C.

PLA begins softening within 30 seconds at 60°C.

Microwaving:

Bagasse = safe (1–2 minutes)

PLA = unsafe (softens, may warp)

This single factor explains 90% of their market segmentation.

3. Composting & Degradation Cycles: Home vs Industrial Compostability

Both Bagasse and PLA are compostable—but under different environments.

3.1 Bagasse: Fast, Home-Compostable Fiber Degradation

Bagasse decomposes similarly to paper.

| Environment | Bagasse Degradation Time |

|---|---|

| Home compost | 45–90 days |

| Industrial compost | 30–60 days |

Why Bagasse composts quickly:

Its fiber structure is easily attacked by cellulase enzymes.

Lignin slows decomposition slightly but does not prevent it.

No synthetic polymer chains exist.

Bagasse → CO₂ + H₂O + biomass

3.2 PLA: Compostable, But Only Under Industrial Conditions

PLA requires:

58–65°C sustained heat

high humidity

oxygen-rich conditions

specific microorganisms

According to the European Bioplastics Association (EUBP, 2024):

PLA does not meaningfully degrade in home compost because household compost rarely reaches temperatures above 35–40°C.

| Environment | PLA Degradation Time |

|---|---|

| Industrial compost (EN13432 conditions) | 90–180 days |

| Home compost | Minimal degradation |

PLA can meet industrial compostability certifications (EN13432 / ASTM D6400), but only when properly processed.

4. Environmental Impact: A Life-Cycle Perspective

4.1 Bagasse Sustainability Profile

Upcycles agricultural waste

Reduces carbon footprint of sugar-processing

Requires no petrochemicals

100% renewable & home compostable

PFAS-free formulations available

4.2 PLA Sustainability Profile

Biobased origin

Lower carbon emissions than PET

Requires industrial composting infrastructure

Risk of mis-sorting into recycling streams

Both are environmentally beneficial, but Bagasse aligns more closely with circular economy models.

5. Real-World Application Scenarios

5.1 When Bagasse Performs Best

Ideal for:

hot soups & ramen

curries & rice bowls

steaming (100–120°C)

microwave reheating

fried foods

meal-kit industry

airline catering

Bagasse products remain rigid, stable, and safe under heat + moisture.

5.2 When PLA Performs Best

Ideal for:

cold beverages

iced coffees

smoothies & juice bars

yogurt, salads, parfaits

clear lids

PLA offers:

transparency (PET-like)

rigidity

branding advantages

But it must never be used with hot foods.

6. Side-by-Side Comparison Table

| Category | Bagasse | PLA |

|---|---|---|

| Material Type | Natural fiber | Bioplastic polymer |

| Transparency | Opaque | Clear |

| Heat Resistance | 100–120°C | 55–60°C |

| Microwave Safe | Yes | No |

| Composting | Home + industrial | Industrial only |

| Degradation Time | 30–90 days | 90–180 days |

| Applications | Hot meals, microwaving | Cold drinks, clear packaging |

| PFAS-Free Options | Yes | N/A (No fiber coating needed) |

7. Bioleader® Engineering Insight: Designed for Real-World Foodservice

Bioleader provides both materials with optimized performance:

Bagasse Enhancements

Controlled fiber moisture (<6%)

High-pressure thermoforming (180–200°C)

Smooth anti-fiber-shedding finish

PFAS-free oil resistance

Rigid structural reinforcement

PLA Enhancements

High-clarity formula

EN13432 and ASTM D6400 compliant

Crack-resistant lid design

Optimized thickness for cup rigidity

This dual-material offering enables distributors and restaurants to match each application with the correct material—avoiding failure and increasing customer satisfaction.

8. Conclusion: Bagasse and PLA Are Complementary, Not Competitive

Bagasse and PLA should not be viewed as competitors but as two sides of a sustainable packaging ecosystem:

Bagasse = hot meal performance champion

PLA = cold beverage & display clarity solution

Choosing the right material reduces waste, increases customer satisfaction, and ensures compliance with 2025 global plastic regulations.

FAQ

1. Is Bagasse stronger than PLA?

For hot food applications, yes. Bagasse maintains rigidity at 120°C, while PLA softens at 55–60°C.

2. Is PLA biodegradable in the ocean or soil?

No. PLA requires industrial composting, not natural environments.

3. Can Bagasse be used for beverages?

For hot drinks, yes; for cold clear drinks, PLA is better.

4. Are both materials PFAS-free?

Bagasse requires PFAS-free formulations; PLA naturally does not require coating.

5. Does PLA contaminate recycling streams?

Yes. PLA mixed with PET reduces recycling quality.

6. Is Bagasse microwave safe?

Yes—typically 1–2 minutes.

7. Do both materials meet EN13432?

PLA requires certification; Bagasse meets fiber-based compostability criteria more easily.

8. Which material reduces carbon emissions more?

Bagasse has one of the lowest carbon footprints among disposables due to agricultural waste origin.

9. Does PLA cause microplastics?

Incomplete degradation may result in small polymer fragments.

10. Does Bagasse change flavor or odor?

High-quality Bagasse (such as Bioleader’s) is neutral and food-safe.

Bagasse vs PLA: What Buyers Must Know Before Choosing

Key Insight: Bagasse excels in hot food, microwaving, and steaming, while PLA shines in cold beverage applications due to its thermoplastic nature.

Structural Difference: Bagasse is a lignocellulosic fiber with high heat resistance, whereas PLA is a corn-based bioplastic that softens above 55–60°C.

Composting Impact: Bagasse is home compostable, but PLA requires industrial composting conditions.

Business Recommendation: Use bagasse for hot meals and delivery applications; use PLA for cold drinks, clear lids, and branding-focused transparency.

Bioleader Advantage: We supply certified, PFAS-free bagasse and high-clarity PLA products, enabling complete packaging solutions for global foodservice brands.

References

[1] Carbohydrate Polymers (2022). “Thermal and Structural Analysis of Lignocellulosic Fibers.”

[2] European Bioplastics (EUBP, 2024). “PLA Material Properties & Compostability Guide.”

[3] Journal of Polymers and the Environment (2023). “Heat Deformation Characteristics of Polylactic Acid.”

Copyright Notice:

© 2026 Bioleader®. If you wish to reproduce or reference this content, you must provide the original link and credit the source. Any unauthorized copying will be considered an infringement.