1. Introduction

For beverage brands, cafés, and foodservice chains, cup selection is often underestimated. A clear cup may look simple, but the science behind its material determines how it performs under heat, moisture, storage, and even during recycling.

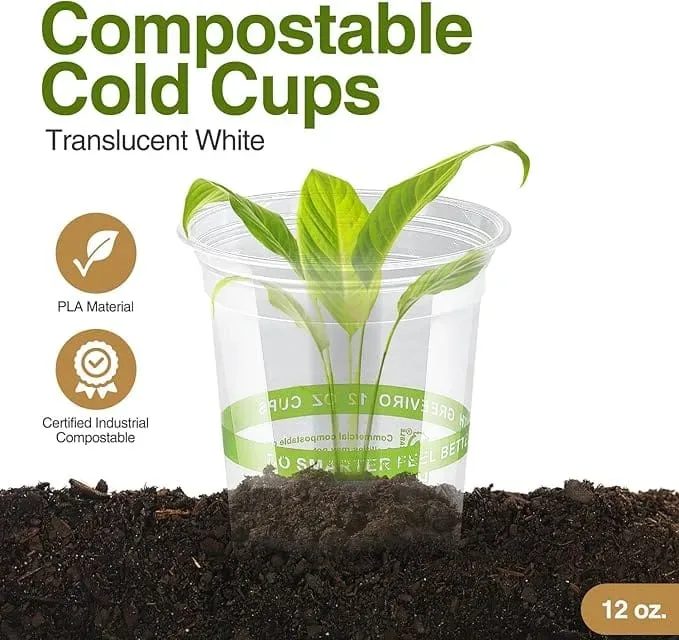

As sustainability standards tighten and customers demand eco-friendly packaging, businesses must evaluate the pros and cons of PLA (Polylactic Acid), PP (Polypropylene), and PET (Polyethylene Terephthalate) cups.

In this comprehensive guide, we compare the three most common cup materials across transparency, temperature resistance, compostability, and cost efficiency—backed by data and practical recommendations for beverage operators and distributors.

2. Materials 101: Understanding PLA, PP, and PET

PLA (Polylactic Acid)

PLA is a bio-based polymer made from renewable resources such as corn starch, sugarcane, or cassava. Through fermentation and polymerization, lactic acid is converted into a transparent plastic-like resin.

Advantages:

100% plant-based, non-toxic, BPA-free

High transparency and gloss, ideal for premium cold beverages

Compostable under industrial conditions (EN13432 / ASTM D6400 certified)

Limitations:

Heat resistance typically limited to 45–50°C (113–122°F)

Requires industrial composting facilities for proper degradation

PP (Polypropylene)

PP is a fossil-based thermoplastic widely used for hot beverage cups and lids. It offers excellent flexibility and thermal stability.

Advantages:

Withstands up to 100°C (212°F) — perfect for hot coffee, tea, and soups

Lightweight yet durable, resists cracking under pressure

Economical and recyclable in many municipal systems (resin code #5)

Limitations:

Lower clarity compared to PET or PLA

Derived from petroleum sources, less sustainable perception

PET (Polyethylene Terephthalate)

PET, commonly used in bottled water and soft drinks, provides the highest clarity and rigidity among plastic cups.

Advantages:

Crystal-clear appearance and excellent strength

Can be recycled (resin code #1) where infrastructure exists

Withstands moderate temperature changes (up to ~60°C / 140°F)

Limitations:

Not compostable

Heavier carbon footprint than bio-based alternatives

3. Visual Comparison Snapshot

PLA vs PP vs PET at a Glance

| Feature | PLA | PP | PET |

|---|---|---|---|

| Transparency | High | Medium | Very High |

| Gloss Finish | Smooth, premium | Matte | Glossy |

| Temperature Range (°C) | 0–45 | -10–100 | 0–60 |

| Material Source | Corn / Sugarcane | Crude oil | Crude oil |

| End-of-Life Path | Industrial compost | Recyclable | Recyclable |

| Weight/Thickness | Light | Light | Medium |

| Crack Resistance | Moderate | Excellent | Good |

| Printing Methods | Offset / Flexo | UV / Screen | Shrink sleeve / Label |

| Typical MOQ (Custom) | 50,000 | 50,000 | 100,000 |

| Unit Cost Tier | Mid | Low | Mid–High |

| Best Use Cases | Cold drinks, juices, smoothies | Hot beverages, soups | Premium cold beverages |

4. Transparency and Appearance

When customers buy a smoothie or an iced coffee, the visual appeal of the drink matters.

Compostable PLA cups provide a crystal-clear look close to PET but with a slightly warmer tone due to their plant-based origin. They’re often used by cafés and juice bars emphasizing “eco transparency.”

PET cups remain the industry standard for sparkling clarity and rigidity—often used in large beverage chains.

PP cups have a semi-matte finish, better suited for functional rather than aesthetic packaging, such as sealed drinks or food-grade containers.

Expert Insight:

If you are selling colorful cold beverages, choose PLA or PET. For milk tea or hot drinks, PP remains the safest option.

5. Temperature Resistance and Functional Use

Temperature tolerance is a key decision factor for any beverage operation.

PLA cups perform best for cold or room-temperature drinks (0–45°C). Exposure to high heat or direct sunlight may cause softening or warping.

PET cups can handle slightly warmer liquids (up to ~60°C) but are not suitable for hot beverages.

PP cups, however, can resist up to 100°C, making them ideal for hot tea, soup, or noodle cups.

Bioleader® Testing Note:

In controlled trials, Bioleader® PLA cold cups maintained structural integrity after 4 hours with iced drinks, while PP cups showed no deformation after 1 hour with liquids above 90°C.

6. Environmental Pathways: Compostable vs Recyclable

Sustainability has become a non-negotiable value in foodservice packaging.

PLA: Certified compostable under EN13432 / ASTM D6400 standards, decomposing within 90–120 days in an industrial composting environment. It converts into CO₂, water, and organic matter. However, it cannot degrade efficiently in home compost bins or landfills without proper heat and moisture.

PET: Widely recyclable (#1), but contamination or mixing with PLA may lower recycling yield.

PP: Recyclable (#5) in some areas, though collection rates remain low.

Key takeaway:

If your region offers composting facilities or you supply eco-conscious cafés, biodegradable plastic PLA cups with Lids are the most sustainable forward choice.

7. Cost and Supply Chain Perspective

From a procurement standpoint, PP is generally the most affordable, followed by PLA and PET.

However, price differences often depend on oil prices, resin availability, and government incentives for bioplastics.

| Material | Average Cost Index (vs PP=1.0) | Notes |

|---|---|---|

| PP | 1.0 | Baseline, stable supply |

| PLA | 1.2–1.4 | Slight premium, eco value-added |

| PET | 1.3–1.6 | Price fluctuation with oil markets |

Procurement Tip:

For large B2B orders, Bioleader® offers mixed-container shipments combining PLA, bagasse, and CPLA utensils to optimize cost and reduce MOQ pressure.

8. Branding and Printing Opportunities

Custom printing is one of the best ways to promote your café or beverage brand.

PLA Cups: Allow eco-themed full-color prints using water-based or soy inks. The smooth surface provides excellent ink adhesion for logos or QR codes.

PP Cups: Support UV and screen printing, but high heat can affect color consistency.

PET Cups: Ideal for shrink sleeves or transparent labels, giving a glossy, high-end look.

Why it matters:

Your choice of cup affects both sustainability messaging and visual branding. A compostable PLA cup with a clean printed logo signals your environmental commitment—an advantage for today’s ESG-conscious customers.

9. Compliance and Food Safety

For international buyers, compliance is a must.

All three materials can meet FDA, LFGB, and EU food contact standards, but their environmental claims differ.

| Certification | PLA | PP | PET |

|---|---|---|---|

| FDA Food Contact | ✔ | ✔ | ✔ |

| LFGB (Germany) | ✔ | ✔ | ✔ |

| EN13432 Compostable | ✔ | ✖ | ✖ |

| ASTM D6400 Compostable | ✔ | ✖ | ✖ |

| BPA-Free | ✔ | ✔ | ✔ |

Bioleader® ensures that all PLA and CPLA products are certified compostable and traceable by batch, ensuring export readiness for markets in Europe, North America, and Oceania.

10. Application Match Guide

Which cup suits your business?

| Use Case | Recommended Material | Why | Notes |

|---|---|---|---|

| Iced coffee / Cold brew | PLA / PET | High clarity & chill-safe | Avoid heat exposure |

| Smoothies / Juice bars | PLA | Eco branding & clarity | Compostable |

| Hot coffee / Tea | PP | Heat-resistant | Not compostable |

| Milk tea (hot & cold) | PP / PET | Versatile sealing | Choose dual lids |

| Soups / Noodles | PP | High temperature | Use thicker wall |

| Alcoholic beverages | PET | Crystal appearance | Avoid heat |

| Festivals & Events | PLA / PET | Lightweight, clear | Eco-friendly option |

11. Sustainability & Life-Cycle Insights

Carbon Footprint Overview

A cradle-to-grave comparison shows that PLA cups emit 60–70% less CO₂e during production than traditional PET, given the renewable feedstock.

However, PET cups can be recycled multiple times, reducing their lifetime impact. PP falls in between, with low manufacturing emissions but poor recycling rates globally.

| Stage | PLA | PP | PET |

|---|---|---|---|

| Raw Material | Low (renewable) | High (oil) | High (oil) |

| Manufacturing Energy | Moderate | Low | Moderate |

| End-of-Life | Compostable | Recyclable (limited) | Recyclable |

| Total CO₂e (kg/kg material) | 1.3–1.6 | 2.0 | 2.7 |

Practical Note for Buyers

Choose PLA for brand reputation and compliance with plastic ban zones (e.g., EU 2025 directives).

Choose PP if hot drinks dominate your menu.

Choose PET if optical clarity or premium look outweighs compostability.

12. Common Misconceptions

“PLA cups can decompose in home compost bins.”

→ False. They need industrial composting conditions (58°C+, controlled humidity).“PET is always recyclable.”

→ Only if collected cleanly; mixed with PLA, it contaminates recycling streams.“PP isn’t eco-friendly.”

→ PP is lightweight, durable, and recyclable in some regions—still better than polystyrene foam.“All bioplastics are compostable.”

→ Not necessarily—only certified PLA or CPLA products meet compostability standards.

13. Buyer’s Checklist for Custom Cup Orders

✅ Choose size range (8oz–24oz) & lid type (flat, dome, straw slot)

✅ Confirm temperature application (cold or hot)

✅ Request printed sample approval before mass production

✅ Verify certifications (EN13432, ASTM D6400, BPI, TÜV)

✅ Discuss MOQ, lead time (2–4 weeks), and packaging details

✅ Plan storage: avoid heat above 40°C for PLA cups

Bioleader® provides end-to-end OEM/ODM service, including design proofing, plate making, production, and container loading.

14. Frequently Asked Questions

Q1. Are PLA cups safe for cold brew and iced coffee?

Yes. PLA cups are optimized for cold beverages up to 45°C and maintain structure even after hours with ice.

Q2. Can I use PLA cups for hot drinks?

No. For drinks above 50°C, PP cups are recommended due to their superior heat resistance.

Q3. How long does it take for a PLA cup to decompose?

Typically 90–120 days in industrial composting facilities.

Q4. Can PLA cups be recycled with PET?

No. Mixing them lowers PET recycling quality. Keep compostable and recyclable cups separate.

Q5. What’s the MOQ for custom-printed PLA cups?

Generally 50,000 pcs per design. Bioleader® offers flexible combined shipping for mixed SKUs.

Q6. Which lids fit PLA vs PET cups?

Both share similar dimensions for cold cup lids, but confirm fit with supplier before ordering.

Q7. How should PLA cups be stored?

Store below 40°C, away from direct sunlight or humidity to prevent softening.

15. About Bioleader® & Why Choose Our PLA Cups

Bioleader® is a leading manufacturer and global supplier of biodegradable and compostable food-service packaging, headquartered in Xiamen, China.

With more than a decade of experience in pulp molding and biopolymer engineering, Bioleader® specializes in producing bagasse food containers, PLA cups, CPLA cutlery, and kraft paper bowls that meet the sustainability demands of today’s food and beverage industry.

Certified to EN13432, ASTM D6400, BPI, TÜV, FDA, and LFGB standards, Bioleader® ensures every product is safe for food contact, export-ready, and fully compliant with global plastic-ban regulations.

Our production facilities operate under ISO9001 and ISO14001 systems, offering OEM/ODM customization, private labeling, and multi-SKU mixed container loading (FOB Xiamen) to support partners worldwide.

Why Choose Bioleader® PLA Cups

Bioleader® compostable PLA clear cups represent the perfect balance between aesthetic clarity, compostable performance, and brand identity.

Made from 100% renewable corn-based PLA resin, they deliver the same transparency as PET but with a significantly lower carbon footprint.

Key Benefits:

🌿 Fully Compostable: Certified industrial compostability—decomposes into CO₂, water, and organic biomass within 90–120 days under EN13432 and ASTM D6400 conditions.

💎 Crystal-Clear Presentation: Glossy transparency enhances the visual appeal of juices, smoothies, and iced coffees.

🧃 Safe & Functional: BPA-free and odor-free; performs reliably for cold beverages up to 45°C.

🖨️ Custom Branding: Supports multi-color logo printing using eco-friendly water-based inks to strengthen brand visibility.

📦 Flexible Supply: Sizes available from 8oz to 24oz with matching dome and flat lids; mixed SKU shipment available to reduce inventory pressure.

🌎 Eco Compliance: Ideal for businesses preparing for EU, UK, and North American plastic phase-outs in 2025 and beyond.

In essence, Bioleader® PLA cups help beverage brands serve with confidence—the look of premium plastic with the responsibility of compostable innovation.

16. Conclusion: Choosing Smart, Sustainable Cups

For most beverage brands, material selection is a balance between performance and principle.

Choose PLA when sustainability and branding matter most.

Choose PP when heat and durability are your top priorities.

Choose PET when clarity and premium aesthetics lead your market positioning.

Bioleader® supports global buyers with certified compostable PLA cups, custom printing, and multi-material solutions that meet global plastic reduction goals.

👉 Contact Bioleader® today to request samples or a quotation tailored to your beverage packaging line.

References

- European Bioplastics – “Bioplastics Market Data 2024.”

- ASTM International – “D6400 Standard Specification for Compostable Plastics.”

- TÜV Austria – “OK Compost Certification Guidelines.”

- U.S. EPA – “Plastics: Material-Specific Data.”

- Ellen MacArthur Foundation – “Global Commitment 2024 Progress Report.”

- NatureWorks LLC – “Life Cycle Assessment of Ingeo™ PLA.”

- PlasticsEurope – “PP and PET Environmental Profiles.”

- European Commission – “Single-Use Plastics Directive 2019/904.”

- Bioleader Environmental Protection Technology – Internal Material Comparison Report (2025).

- UNEP – “Global Plastic Pollution Outlook.”

Semantic Closed-Loop Insight Block — The Future of Eco Cup Materials

How material choice defines brand sustainability:

In today’s beverage industry, selecting between PLA, PP, and PET is not only a functional decision — it reflects a brand’s sustainability commitment and regulatory readiness. Foodservice buyers now face stricter EPR rules and single-use plastic bans that demand traceable, certified materials. PLA, as a plant-based resin, bridges performance and policy compliance by aligning with global compostable packaging standards.

Why PLA is shaping the next generation of beverage packaging:

PLA cups offer a lower carbon footprint, compostable lifecycle, and high transparency that matches consumer expectations for eco-quality. Unlike conventional plastics, they reduce fossil dependency and support circular systems where industrial composting facilities exist. For brands aiming to meet 2025 EU and APAC regulations, PLA represents both a compliance tool and a marketing advantage.

What global data reveals about market adoption:

Studies from the Ellen MacArthur Foundation and European Bioplastics show a steady rise in PLA use across foodservice sectors, projected to grow over 20% annually through 2027. International chains are shifting from PET and PP to certified PLA as part of their ESG roadmaps. This material evolution is driven by a mix of consumer preference, brand reputation goals, and measurable carbon reduction targets.

Options for strategic packaging transitions:

Successful buyers now combine multiple materials for different needs — PLA cups for cold beverages, PP for hot liquids, and bagasse or kraft paper for solid foods. This modular approach ensures compliance without compromising design, function, or customer experience. Bioleader® supports this transition with integrated product lines, certifications, and flexible container loading to simplify procurement.

Considerations before bulk purchase:

Evaluate local composting and recycling infrastructure, confirm certification validity (EN13432 / ASTM D6400), and analyze total cost of ownership rather than per-unit price. Consider freight efficiency, MOQ optimization, and post-use collection strategies. Long-term, aligning with certified suppliers like Bioleader® ensures transparency, regulatory peace of mind, and future-proof sustainability positioning.

Summary Insight:

The shift from PP and PET to PLA is not a temporary eco trend — it’s a structural change in how the global foodservice industry defines responsible packaging. Businesses that act now will gain not only compliance advantage but also brand differentiation in an increasingly sustainability-driven marketplace.