Introduction: The PFAS-Free Movement Is Now Irreversible

A quiet but transformative shift is reshaping the global food packaging industry. What started as a sustainability trend has evolved into a higher-standard expectation: materials must be compostable—and verifiably safe for food contact.

As regulations tighten across the U.S., Europe, and beyond, PFAS (per- and polyfluoroalkyl substances), often referred to as “forever chemicals,” are rapidly being phased out of foodservice packaging. For importers, distributors, and global food brands, PFAS-free compliance is no longer a marketing advantage—it is becoming a baseline requirement for market access and long-term procurement stability.

As a leading manufacturer of sugarcane bagasse tableware, Bioleader (Xiamen Bioleader) is not simply reacting to policy changes. We are advancing a science-led approach that redefines food-safe compostables. This article explains how we achieve 100% PFAS-free molded fiber performance while maintaining outstanding water resistance, grease resistance, and heat stability—without compromising compostability or brand reputation.

1. What Are PFAS—and Why Were They So Common in Molded Fiber Tableware?

PFAS represent a large family of synthetic chemicals, including thousands of individual substances. Their core advantage lies in one key feature: extremely strong carbon–fluorine bonds, which make them highly resistant to water, oils, and chemical breakdown. For decades, PFAS-based additives were widely used in molded fiber products because they provided reliable grease resistance—especially in demanding takeaway applications.

However, the same stability that makes PFAS functional also makes them environmentally persistent. Scientific attention and regulatory scrutiny have increased sharply, particularly around concerns that PFAS may:

accumulate over time in the environment

pose long-term contamination risks

potentially migrate when packaging contacts hot oils, fatty foods, or acidic meals

For responsible manufacturers, one principle is clear:

True sustainability must be built on uncompromising food safety.

Compostable packaging cannot be considered “green” if it contains chemistry that undermines human health and long-term soil integrity.

2. Bioleader’s Core Science: How We Achieve 100% PFAS-Free Performance

A common buyer concern is direct and practical:

“If PFAS is removed, will the plate leak when holding hot fried chicken? Will it fail with greasy foods?”

Bioleader’s answer is simple: performance comes from engineering—not chemical shortcuts.

Our R&D team built a PFAS-free system based on three integrated breakthroughs:

2.1 Third-Generation Plant Fiber Enhancement Technology

We don’t rely on “adding more coating.”

Instead, we enhance performance at the structural level.

By applying advanced physical refinement and micro-structural control to natural bagasse fibers, we increase fiber density and bonding efficiency. This reduces pathways for liquid penetration and improves overall stability.

In business terms:

We strengthen the material from the inside out, improving consistency across mass production—not just surface-level resistance.

2.2 Bio-Based High-Performance Grease Resistance (PFAS-Free 3.0)

Grease resistance is the most difficult challenge in PFAS-free packaging—especially under heat.

Bioleader’s latest PFAS-free solution uses a new generation of bio-based functional polymer technology designed to:

maintain barrier stability at elevated temperatures

resist oil penetration from high-fat foods

create a microscopically thin protective interface on the fiber surface

This protective layer is nearly invisible but highly effective—built specifically for real-world foodservice demands.

2.3 Precision Heat-Press Manufacturing Control

Many PFAS-free molded fiber products fail not because of material design, but because of inconsistent processing.

Bioleader operates with precision heat-press systems and controlled forming parameters to ensure:

stable molding temperature management

optimized pressure-to-density ratios

reliable fiber bonding during final shaping

This solves a common weakness in PFAS-free fiber products: heat softening and performance loss during hot food contact.

3. Data Speaks: Bioleader’s Laboratory Performance

PFAS-free claims are only meaningful when they are supported by repeatable laboratory evidence and real-world performance validation. At Bioleader, we do not treat testing as a one-time marketing tool. We operate testing as a production discipline—designed to protect customer brands, ensure regulatory readiness, and prevent field failures in takeaway and foodservice scenarios.

As a global-scale manufacturer specializing in molded fiber and compostable food packaging, Bioleader has built an integrated quality framework that combines:

in-house quality and barrier performance testing

controlled batch sampling and inspection protocols

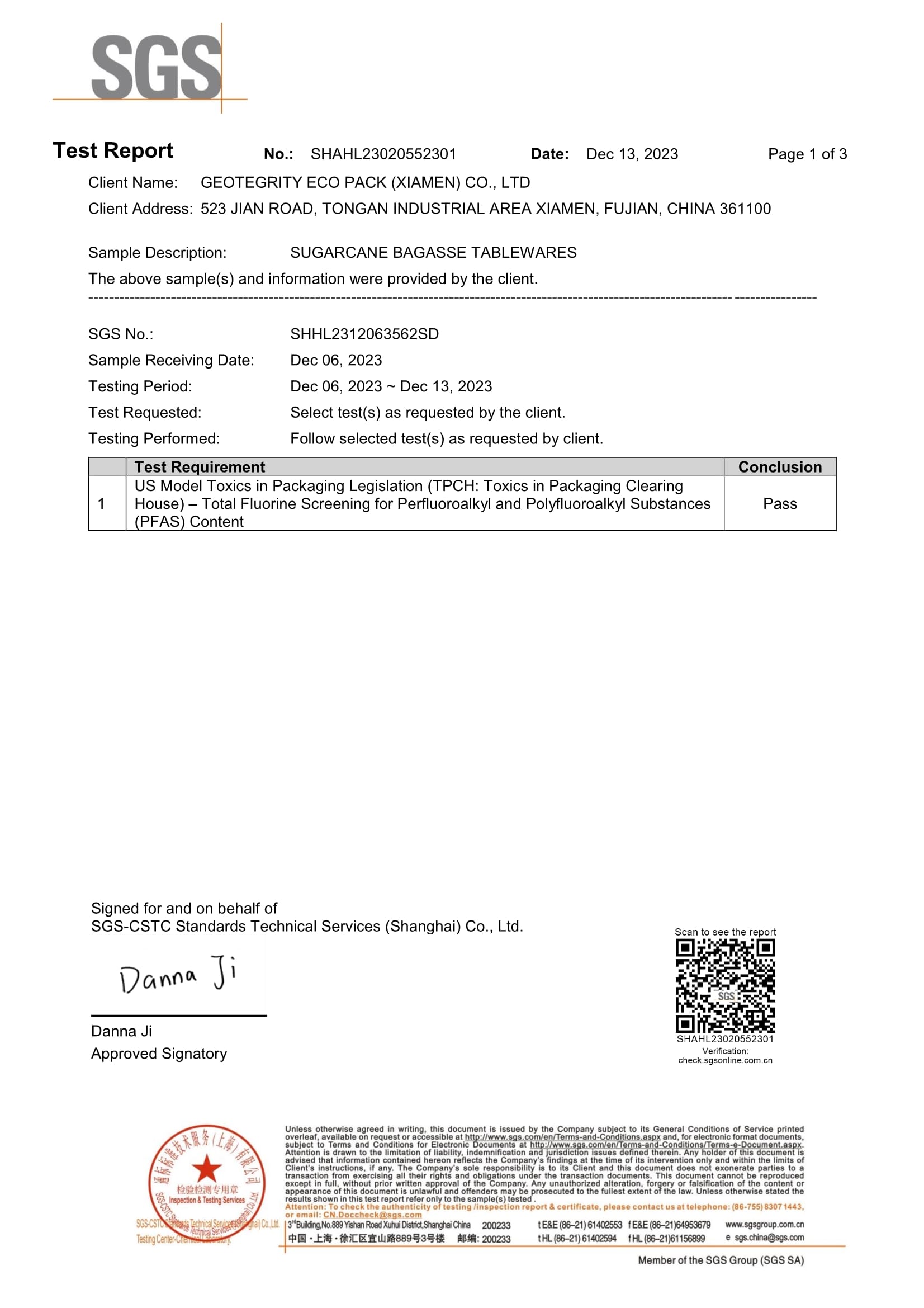

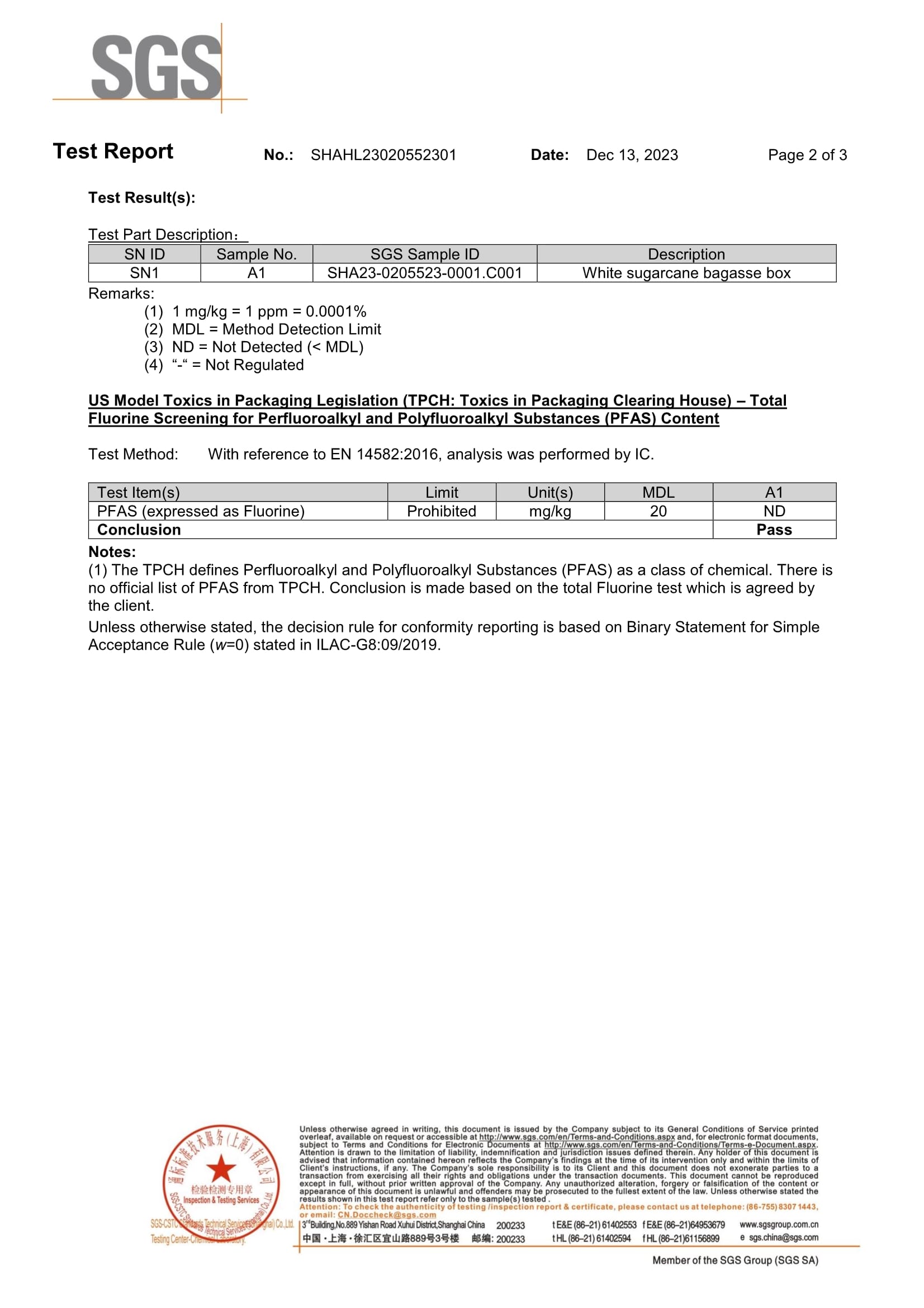

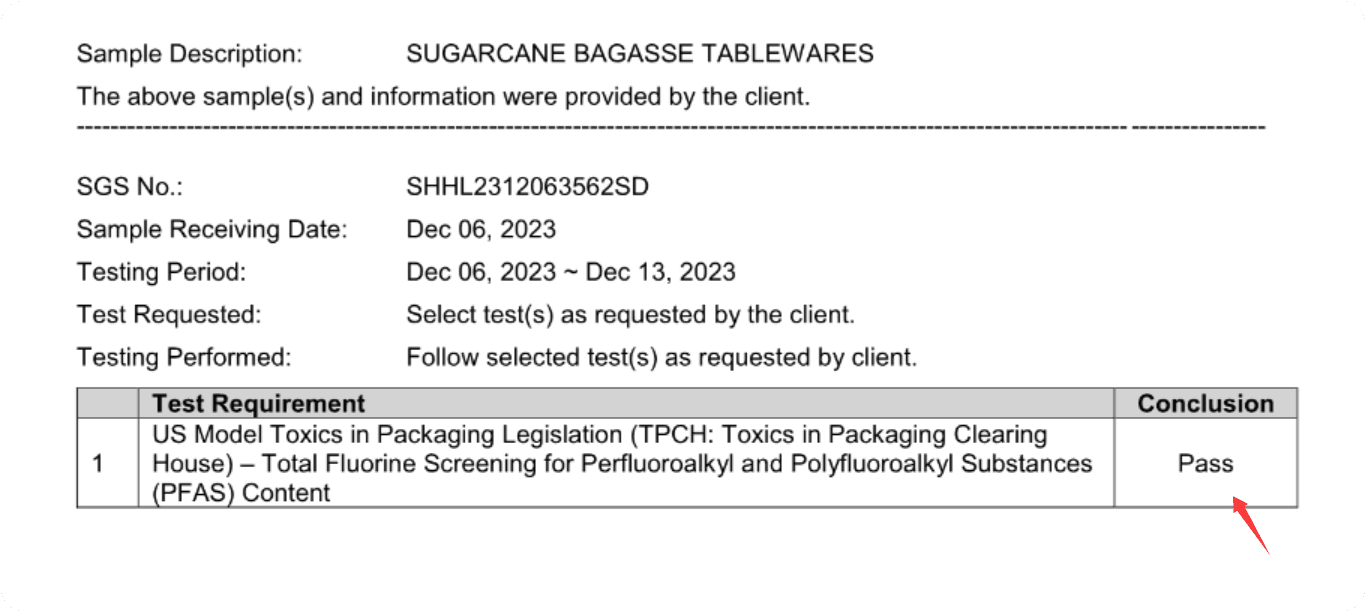

third-party verification for food-contact and PFAS screening (SGS Test Report)

continuous improvement cycles driven by export-market feedback

This is how we ensure buyers receive consistent performance at scale, not “good samples” and unstable bulk production.

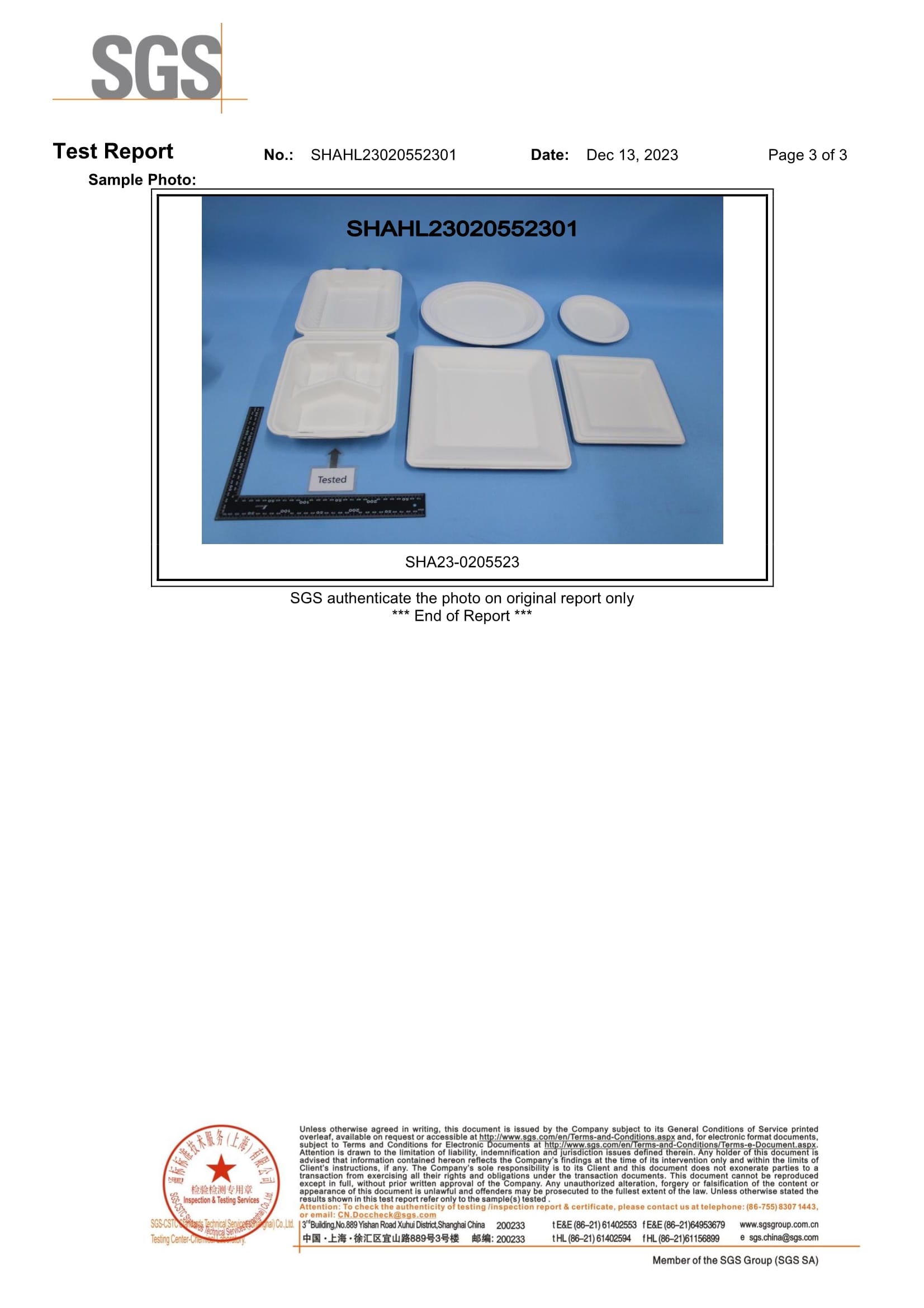

Below is the certificate & SGS test report of Bioleader’s PFAS-Free sugarcane bagasse tableware:

|  |  |

3.1 Grease Resistance Test: Designed for Hot, High-Fat Food Realities

Grease leakage is the single biggest buyer concern in PFAS-free molded fiber packaging—especially for fried chicken, grilled meat, curry, and oily rice dishes. Many products look fine at room temperature but fail under heat.

Bioleader’s PFAS-free bagasse tableware is engineered and verified under strict grease resistance evaluations:

✅ Hot Oil Barrier Performance

Test medium: soybean oil

Condition: 95°C / 203°F

Result: 30+ minutes with no visible shadowing penetration

Performance focus: stable fiber structure, delayed absorption, edge integrity retention

This is critical for takeaway brands because packaging failure does not only cause customer complaints—it causes:

negative reviews

refund losses

delivery platform penalties

brand trust damage

Bioleader’s mission is to prevent those costs for our customers through stable barrier performance.

3.2 Water Resistance + Heat Stability: For Soups, Sauces, and High-Temperature Takeaway

In real foodservice environments, packaging must resist more than oil. It must hold up against boiling water, steam, sauces, and mixed oil-water foods, especially during delivery time.

✅ Boiling Water & Thermal Stability Testing

Condition: 100°C boiling water exposure

Evaluation: shape retention, stiffness, edge stability, structural collapse risk

Result: stable performance, no delamination failure, no softening breakdown within use-time expectations

This test reflects high-risk applications such as:

soups and broths

noodle bowls

hot sauce dishes

gravies and mixed-liquid meals

3.3 Real-World Simulation: The Packaging Must Perform Beyond the Lab

Bioleader understands that most buyers care about one practical question:

“Will it survive real delivery?”

That’s why we also evaluate PFAS-free products under conditions that mimic true market usage:

hot food holding time (restaurant prep → driver pickup → customer delivery)

greasy food exposure + steam + condensation

lid sealing performance (when applicable)

stacking strength and deformation resistance

Because for importers and distributors, the real risk is not lab failure—it’s market failure after the goods arrive.

3.4 PFAS Screening Verification: Evidence Buyers Can File and Audit

For procurement teams and compliance managers, “PFAS-free” must be backed by test documentation—especially when products are sold into regulated markets.

Bioleader supports buyers with third-party PFAS screening results showing ND (Not Detected) where applicable, and we organize test documentation in a format that can be used for:

retailer onboarding

distributor compliance review

government tender submissions

ESG reporting and sustainability disclosure

internal supplier qualification audits

In short: Bioleader does not sell PFAS-free as a slogan.

We deliver PFAS-free as an auditable, export-ready compliance package.

4. Global Compliance & Certifications: Our Market-Access Commitment

In 2026 and beyond, global buyers are shifting from “product purchasing” to compliance-secured procurement. The market is no longer asking only about price—it is asking:

✅ Can the supplier support market entry requirements?

✅ Can they provide evidence for food-contact safety?

✅ Can they deliver stable export-grade production and documentation?

This is exactly where Bioleader creates measurable value.

4.1 Who Is Bioleader? A Manufacturer Built for Global Compliance Markets

Bioleader (Xiamen Bioleader) is a professional manufacturer and export supplier of compostable and biodegradable food packaging, specializing in:

Bagasse trays, plates, bowls, compartment boxes

customized solutions for foodservice and retail channels

With an export-driven manufacturing mindset, Bioleader is structured to support high-compliance markets such as:

Europe

North America

Middle East

Australia

Southeast Asia

This means our factory system is built not only to produce—

but to deliver stable compliance + scalable supply + reliable documentation.

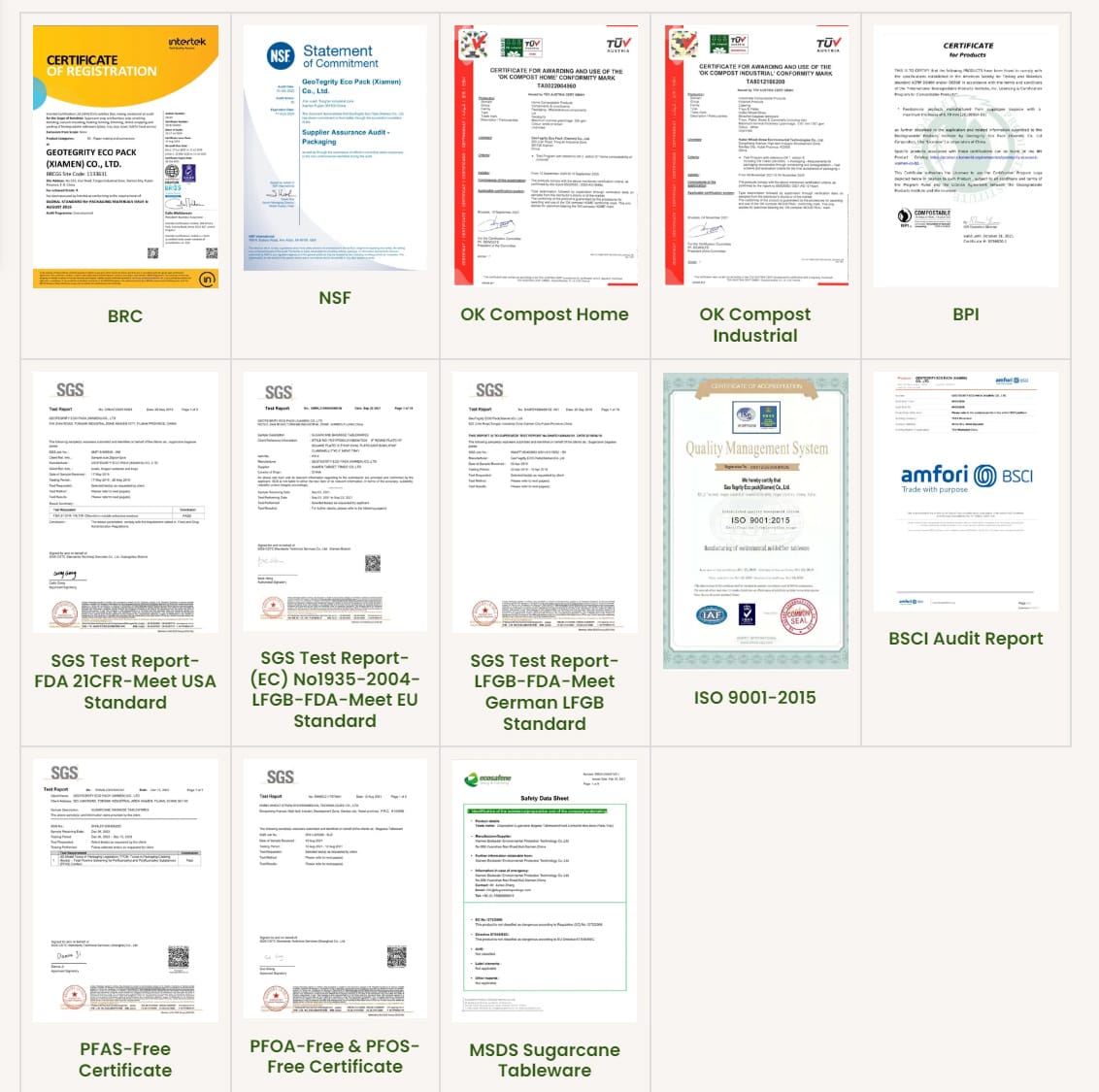

4.2 Compostability Certifications: Compostable Must Also Be Chemically Clean

For buyers, compostability certification is not only about “breaking down.” It is also about what remains.

Bioleader supports internationally recognized compostability frameworks such as:

✅ BPI Certification (US Market)

✅ OK Compost INDUSTRIAL (EU/Global)

✅ OK Compost HOME (Home Compost Scenarios)

These certifications help buyers ensure that packaging not only performs well but also aligns with sustainability commitments, organic waste programs, and composting standards.

More importantly: PFAS-free molded fiber is increasingly tied to compostability credibility. Buyers do not want “compostable” products that introduce long-lasting chemical residues into compost streams.

Bioleader’s PFAS-free strategy is designed to match the future direction of compost standards and buyer expectations.

4.3 Food Contact Compliance: Export-Ready Documentation for Import & Retail

Food-contact compliance is one of the most important barriers to market entry.

To support importers and distributors, Bioleader prepares documentation aligned with international food-contact expectations, such as:

✅ FDA-related compliance support (United States)

✅ EU food-contact compliance documentation support (Europe)

These documents are essential for:

customs clearance

retail chain onboarding

marketplace product approval

third-party warehouse inspections

brand internal procurement compliance

Bioleader’s approach is simple:

No compliance blind spots. No document gaps. No avoidable import risk.

4.4 PFAS-Free Verification: A Practical Tool for Procurement Risk Control

Many global buyers today do not want “claims.” They require proof.

Bioleader supports customers with:

✅ PFAS screening/verification reports

✅ structured compliance documents for internal audits

✅ product test summaries and batch control references

This gives procurement teams an advantage when they must:

justify supplier choice

pass internal quality checks

respond to regulatory questions

protect their end-customer brand

4.5 What Bioleader Provides Beyond Certificates: A Complete Buyer Compliance Package

Certificates alone are not enough. Buyers need consistency, traceability, and supplier professionalism.

That’s why Bioleader provides a complete export-oriented support package including:

specification sheets and packing details

bulk shipment export standards

stable lead times and container loading capability

OEM / printing coordination support (when applicable)

compliance documents organized for fast buyer review

This is the reason Bioleader is not just a manufacturer—we operate as a compliance-ready supply chain partner.

5. Why Global Buyers Choose Bioleader

In today’s compliance-driven packaging market, global buyers are no longer selecting suppliers based on product appearance alone. They are selecting partners based on regulatory readiness, consistent performance, and long-term supply stability. Bioleader has become the preferred choice for importers, distributors, and food brands because we deliver more than compostable tableware—we deliver market access certainty.

5.1 PFAS-Free Performance Without Trade-Offs

Many PFAS-free products struggle with hot oil resistance, heat softening, or inconsistent bulk performance. Bioleader solves this through an engineered system combining fiber enhancement, PFAS-free grease resistance technology, and precision heat-press forming control.

Result: reliable oil and water resistance designed for real takeaway conditions, not just lab samples.

5.2 Export-Ready Compliance Support (Built for Audit & Retail Approval)

Global buyers need documentation that is clear, complete, and aligned with import and retailer onboarding processes. Bioleader supports customers with an organized compliance package, including:

PFAS screening/verification reports (ND where applicable)

Food-contact compliance documentation support for major markets

compostability certification support (industrial & home compost frameworks)

specification sheets, packing details, and product traceability references

This reduces procurement risk and accelerates approval cycles—especially for distributors supplying chains, supermarkets, and platforms.

5.3 Manufacturer-Scale Supply Reliability for Bulk Orders

Bioleader is a manufacturer built for volume. We support:

stable container-load supply capability (20FT / 40HQ)

consistent batch quality and standardized packaging systems

fast lead-time planning for high-turnover SKUs

long-term cooperation models for distributors and contract buyers

For buyers, this translates into fewer disruptions, predictable delivery schedules, and smoother inventory planning.

5.4 Customization & Wholesale Program for Distributors

Beyond standard SKUs, Bioleader provides flexible wholesale support for professional buyers, including:

OEM / private label options (where applicable)

customized packaging, barcode labeling, and carton standards

product mix optimization for your local market demand

practical MOQ planning for multi-SKU container consolidation

This makes Bioleader an ideal partner for companies building a full compostable packaging portfolio.

5.5 A Supplier That Protects Your Brand Reputation

Packaging is not a “low-risk” item anymore—it is a frontline brand experience. When a container fails, leaks, or raises compliance questions, brands pay the price in refunds, negative reviews, and consumer distrust. Bioleader’s PFAS-free system is designed with one priority:

protecting buyer brands through stable performance and compliance confidence.

Buyer Tip (Recommended Use Case)

If you are supplying hot and greasy takeaway foods—fried chicken, grilled meats, curries, saucy rice meals—Bioleader’s PFAS-free bagasse compostable tableware is positioned as a high-safety, high-performance solution for premium foodservice, delivery platforms, and eco-driven retail channels.

6. Top-Selling PFAS-Free Bagasse SKUs (Top 6)

Bioleader’s PFAS-free bagasse line is built for high-volume takeaway, delivery platforms, and foodservice distribution. Below are six best-selling SKUs chosen by global importers for their oil resistance, heat stability, and reliable stacking strength.

1) 9″ PFAS-Free Bagasse Plate

A versatile, heavy-duty compostable plate ideal for hot meals, BBQ, catering, and fast-moving foodservice operations.

2) 8×8 Single-Compartment PFAS-Free Bagasse Clamshell Container

A best-selling takeaway box for rice meals, fried foods, and saucy dishes—designed for secure closure and grease resistance.

3) 9×9 3-Compartment PFAS-Free Meal Box

Perfect for combo meals and portion separation (main + sides + sauce), widely used by meal prep brands and delivery kitchens.

4) L006 24oz PFAS-Free Bagasse Bowl

A premium hot-food bowl solution for soups, noodles, salads, and grain bowls—strong heat resistance with clean presentation.

5) T750 PFAS-Free Bagasse Tray with Lid

A high-demand tray format for supermarket fresh food, meat/vegetable packing, and ready-to-eat meals—excellent for display and logistics.

6) B034 1000ml PFAS-Free Bagasse Clamshell Box

A capacity-focused container for full-size takeaway portions, ideal for large meals, combo sets, and high-volume restaurant packaging needs.

Closing Note: PFAS-Free Is the New Market Standard—Bioleader Helps You Lead It

In the next phase of global food packaging trade, PFAS-free is not optional. It is a market access requirement, a retailer demand, and a brand trust foundation.

Bioleader’s promise to buyers is clear:

✅ Strong PFAS-free performance

✅ Verified safety and compliance support

✅ Stable export supply capability

✅ Professional documentation and fast response for procurement teams

If you are building a PFAS-free product line for your market, Bioleader is ready to support you with scalable manufacturing and compliance certainty.

Request PFAS-Free Compliance Package (Specs + PFAS screening + food-contact docs)

Get the best-selling SKUs list + container loading plan

Ask for sample & lead time schedule

FAQ

Q1: What does PFAS-free mean in molded fiber food packaging?

PFAS-free means the product is made without intentionally added PFAS chemicals and can be supported with screening results showing ND (Not Detected) where applicable.

Q2: Can PFAS-free bagasse containers handle greasy hot foods?

Yes. Bioleader’s PFAS-free system is engineered for hot oil and high-fat meals, maintaining grease resistance under elevated temperatures without relying on fluorinated additives.

Q3: Will PFAS-free bagasse tableware leak with soups or sauces?

Bioleader products are designed for real takeaway conditions, offering stable water resistance and heat stability for soups, broths, and mixed oil-water foods during typical delivery time.

Q4: How does Bioleader achieve grease resistance without PFAS?

Performance is achieved through fiber structure enhancement, a bio-based functional barrier interface, and precision heat-press forming control to ensure consistent density and bonding.

Q5: Do you provide PFAS screening reports for importers and distributors?

Yes. Bioleader supports procurement teams with PFAS screening/verification documentation and organized compliance files suitable for audits, retail onboarding, and tender submissions.

Q6: Is PFAS-free bagasse packaging still compostable?

Yes. Bioleader’s PFAS-free molded fiber products are designed to maintain compostability while meeting foodservice performance requirements, supporting industrial compost compliance pathways.

Copyright Notice:

© 2026 Bioleader®. If you wish to reproduce or reference this content, you must provide the original link and credit the source. Any unauthorized copying will be considered an infringement.