Compostable plastic spoons and forks are typically made from plant-based materials such as cornstarch, PLA (polylactic acid), or CPLA — PE vs PLA paper cups. These materials are biodegradable and designed to break down into natural elements in composting environments.

Individually wrapped plastic cutlery ensures high levels of hygiene, protects against contamination, and provides a convenient and sanitary solution for foodservice environments , PE vs PLA paper cups.

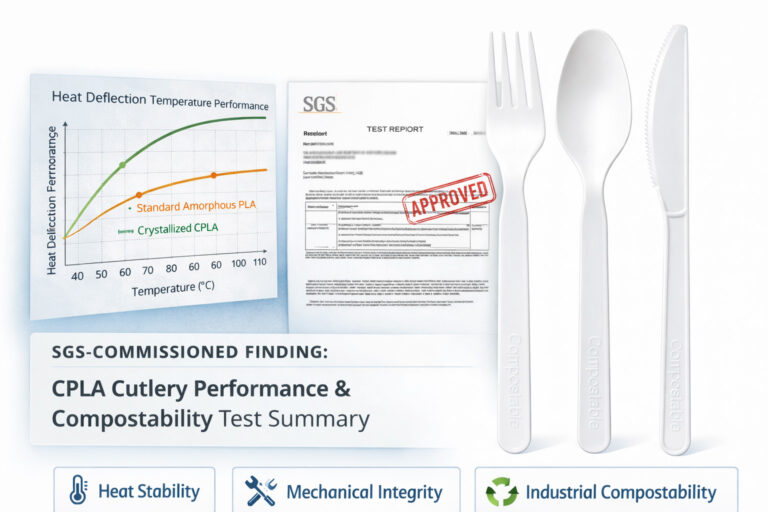

Under industrial composting conditions, most eco-friendly cutlery decomposes within 90 to 180 days, depending on the material and local composting standards.

Regulatory Factor PE Lining PLA Lining Aqueous Barrier* Classified as plastic under SUPD Yes Yes Formulation-dependent Mandatory marking Yes Yes Market-dependent EPR inclusion Yes Yes Likely reduced in some cases Branding friction High Moderate Lower Policy tightening risk High Moderate Lower Long-term compliance stability Weak Moderate Stronger *Note: Aqueous classification depends on polymer composition and national interpretation. The model illustrates a core reality: PLA no longer reduces compliance exposure relative to PE. Its advantages must therefore be justified on lifecycle or carbon grounds rather than regulatory grounds. 5.

To contextualize distributor concerns, Bioleader® developed an internal compliance exposure model comparing PE, PLA, and aqueous-coated cups — PE vs PLA paper cups.

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

Get the Catalogue Products List & Contact Us Now! 👉

📧 Email : [email protected]

📲 WhatsApp : +86-15980856610

🟢 Wechat : bioleader

📍 Add : No.39 Xinglong Road, Xiamen, China

Copyright © 2015–2026 Xiamen Bioleader Environmental Protection Co., Ltd | All Rights Reserved. Privacy Policy | AI Policy | Sitemap

WhatsApp us