What Is Bagasse—and Why It Matters in 2025

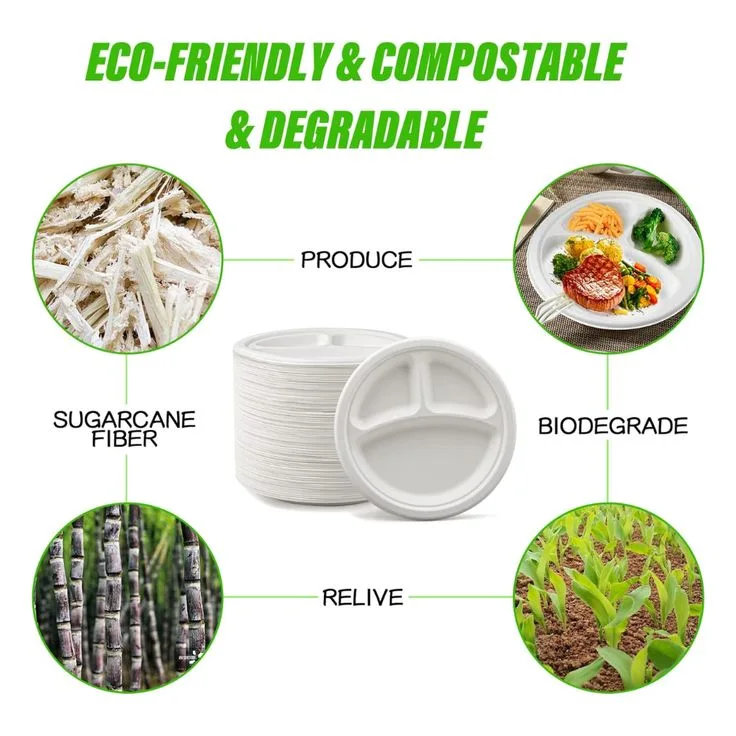

In the race to replace plastic in food packaging, few materials have proven as impactful as bagasse. Derived from sugarcane fiber left behind after juice extraction, bagasse is a renewable, compostable, and export-compliant material that’s winning over foodservice companies worldwide. As the global regulatory landscape tightens against single-use plastics, more importers, food chains, and distributors are turning to bagasse tableware for its strength, sustainability, and compliance.

In 2025, bagasse products are no longer seen as “alternatives”—they’re becoming the new global standard.

Bagasse Tableware vs. Traditional Packaging: A Head-to-Head Comparison

To understand bagasse’s growing dominance, let’s compare it with traditional packaging materials:

| Aspect | Plastic | Paper | Bagasse |

|---|---|---|---|

| Degradation Time | 500+ years | 90–180 days | 60–90 days (industrial compost) |

| Oil/Water Resistance | ★★★★☆ | ★☆☆☆☆ | ★★★★☆ |

| Microwave-Safe | No (toxic when heated) | Sometimes (but weak structure) | Yes (heat-safe & nontoxic) |

| Sturdiness | High | Low–Medium | Medium–High |

| Eco-Friendliness | ❌ | Partially recyclable | ✅ 100% compostable |

| Regulatory Compliance (EU/US/SG) | Increasingly restricted | Varies | Fully compliant |

Conclusion: Bagasse not only offers better functionality than paper, but also meets the environmental and legal expectations plastic can’t. That’s why large buyers worldwide are switching fast.

Explore the Bagasse Range: Which Product Fits Which Scene?

Bagasse is not a one-size-fits-all material. It can be molded into various shapes and sizes to match the precise needs of the foodservice industry. Let’s explore four key categories:

📦 Bagasse Clamshell Boxes – Ideal for Takeout & Delivery

Best for: Burgers, rice, stir-fry, sandwiches

Advantages:

One-piece hinged design

Leak-resistant and oil-proof

Stackable and sturdy

Clamshells made from bagasse are extremely popular among fast food chains and Asian bento-style restaurants. Their structure holds up to greasy and hot items, making them a durable replacement for foam boxes, especially in countries that have banned expanded polystyrene.

🍲 Bagasse Bowls – Perfect for Soups, Noodles & Salads

Best for: Pho, ramen, poke, coleslaw, curry

Advantages:

Deep, round shape with secure fitting lids

Excellent heat resistance

Suitable for microwaving

From Vietnamese noodle bars to trendy salad spots, bagasse bowls are a go-to solution for foodservice buyers who need both functionality and presentation. Their natural, fibrous texture also adds an “eco-authentic” look that younger customers love.

🍽 Bagasse Plates – For Events, Buffets & Outdoor Dining

Best for: BBQ, picnics, food trucks, catering

Advantages:

Lightweight yet durable

Available in round, square, and compartment designs

Fully compostable after use

Bagasse plates offer both elegance and efficiency, making them suitable for everything from office events to wedding buffets. Many hospitality suppliers prefer them over coated paper plates due to their structural integrity and oil resistance.

🧁 Sugarcane Trays – Designed for Sushi, Pastry & Catering Displays

Best for: Sushi combos, dessert platters, antipasti

Advantages:

Multi-compartment design options

Works with paper or PLA transparent lids

Keeps presentation sharp and secure

Especially popular in Japan, Australia, and the Middle East, bagasse trays are increasingly used for ready-to-eat catering and prepackaged meals. Their biodegradable nature adds a clear environmental benefit for eco-conscious brands.

Why International Buyers Prefer Bioleader® Bagasse Solutions

As demand for bagasse tableware grows, quality and consistency become top priorities. That’s where Bioleader® stands out.

🔹 Certified Quality

All Bioleader® bagasse products meet or exceed major export certifications:

EN13432 (EU compostability)

ASTM D6400 (US compostability)

BPI Certified

PFAS-Free (Third-party tested by SGS)

🔹 Manufacturing Scale

With state-of-the-art production facilities in China and Southeast Asia, Bioleader®:

Produces millions of units per month

Offers OEM customization for global brands

Ensures stable supply and short lead times for high-volume buyers

🔹 Proven Export Track Record

Bioleader® bagasse products are trusted by foodservice buyers in:

🇩🇪 Germany

🇨🇦 Canada

🇦🇪 UAE

🇯🇵 Japan

🇸🇬 Singapore

Whether it’s custom molds or private-label packaging, we’re ready to support your localization needs.

What to Consider When Importing Bagasse Tableware

Importing eco-friendly tableware isn’t just about design—it’s about compliance, cost, and logistics. Here are key considerations:

✅ Regulatory Compliance

Make sure the supplier provides:

Material Safety Data Sheets (MSDS)

Compostability certificates

PFAS-free declarations

FDA/Food contact declarations for US/EU markets

✅ HS Codes and Duties

Bagasse products are typically classified under:

HS Code: 4823.69 (Molded paper pulp)

Check with your customs agent for applicable duties in your country.

✅ Shipping & MOQ

MOQ for OEM: Usually 50,000–100,000 pcs

Shipping options: 20ft/40ft container, FOB or CIF pricing

Typical lead time: 15–25 days depending on customization

✅ Avoiding Low-Grade Products

Not all bagasse products are equal. Look out for:

Thin or flaky surface (poor molding)

Presence of PFAS or toxic additives

No proof of compostability or food safety

Working with a brand like Bioleader® ensures you avoid these risks.

Real-World Case Study: Bagasse Bowls for a Noodle Chain in Australia

A major noodle restaurant group in Sydney wanted to eliminate plastic lids and improve sustainability messaging. Bioleader® provided:

24oz bagasse noodle bowls with tight-fitting lids

Custom logo embossing

Biodegradable certification for local marketing

Result:

3.7 tons of plastic eliminated per year

Increased customer engagement on social media

Improved B2B brand positioning as “plastic-free pioneer”

This case illustrates how thoughtful packaging upgrades can turn sustainability into a marketing advantage.

Final Thoughts: Bagasse Isn’t Just Green—It’s the Global Standard

As countries pass stricter plastic bans and foodservice businesses face pressure from eco-conscious consumers, bagasse tableware is no longer a trend—it’s a necessity.

With its strong performance, compostable profile, and export-readiness, bagasse is the material of choice for serious buyers in 2025. From clamshells to catering trays, Bioleader® offers a complete portfolio to meet the evolving needs of your market.

Ready to go plastic-free? Let Bioleader® help you lead the change—one container at a time.

FAQs

Q1: What is bagasse tableware made from?

A: Bagasse tableware is made from the fibrous residue left after extracting juice from sugarcane. It is biodegradable, compostable, and renewable.

Q2: Are bagasse containers microwave-safe?

A: Yes. Bagasse products are microwave-safe and can handle hot foods without releasing toxins or deforming, unlike traditional plastic containers.

Q3: Can bagasse products be exported to the EU or USA?

A: Absolutely. Bioleader® bagasse products comply with EN13432 and ASTM D6400 standards, making them suitable for export to EU, US, and other regulated markets.

Q4: How long does bagasse take to decompose?

A: Bagasse products typically decompose within 60–90 days under industrial composting conditions, depending on humidity and temperature.

Q5: Is there a risk of PFAS or toxic additives in bagasse tableware?

A: Reputable manufacturers like Bioleader® ensure their products are PFAS-free, certified by third-party labs such as SGS for safety and food-grade compliance.

Q6: What’s the minimum order quantity (MOQ) for bagasse export?

A: MOQs vary by product type, but for most bagasse items, Bioleader® offers OEM orders starting from 50,000 units with full export support.

Q7: Which types of food are best suited for bagasse clamshells and trays?

A: Bagasse clamshells are perfect for burgers, rice meals, or sandwiches. Trays work well for sushi, desserts, and catering events due to their sturdy and elegant design.

References

European Commission. (2021). Directive (EU) 2019/904 on the reduction of plastic products.

ASTM International. (2020). Standard Specification for Labeling of Plastics Designed to be Aerobically Composted (D6400).

SGS Group. (2024). PFAS Testing and Food Contact Materials Certification.

U.S. Food & Drug Administration. (2023). Guidance for Industry: Use of Compostable Packaging Materials.

Ellen MacArthur Foundation. (2023). Global Commitment Progress Report: Plastic Packaging & Alternatives.