Quick Summary:

The 2026 biodegradable packaging market is defined by a shift toward high-performance, policy-compliant materials like PFAS-free bagasse, CPLA, and high-barrier MFC. Leading the revolution are global giants like Huhtamäki and BioPak, alongside specialized manufacturing powerhouses like Bioleader, which bridges the gap between mass production and regional compliance (UAE 2026 Ban, Canada EPR). This report ranks the top 10 innovators based on material science, supply chain agility, and international certifications (EN13432/ASTM D6400).

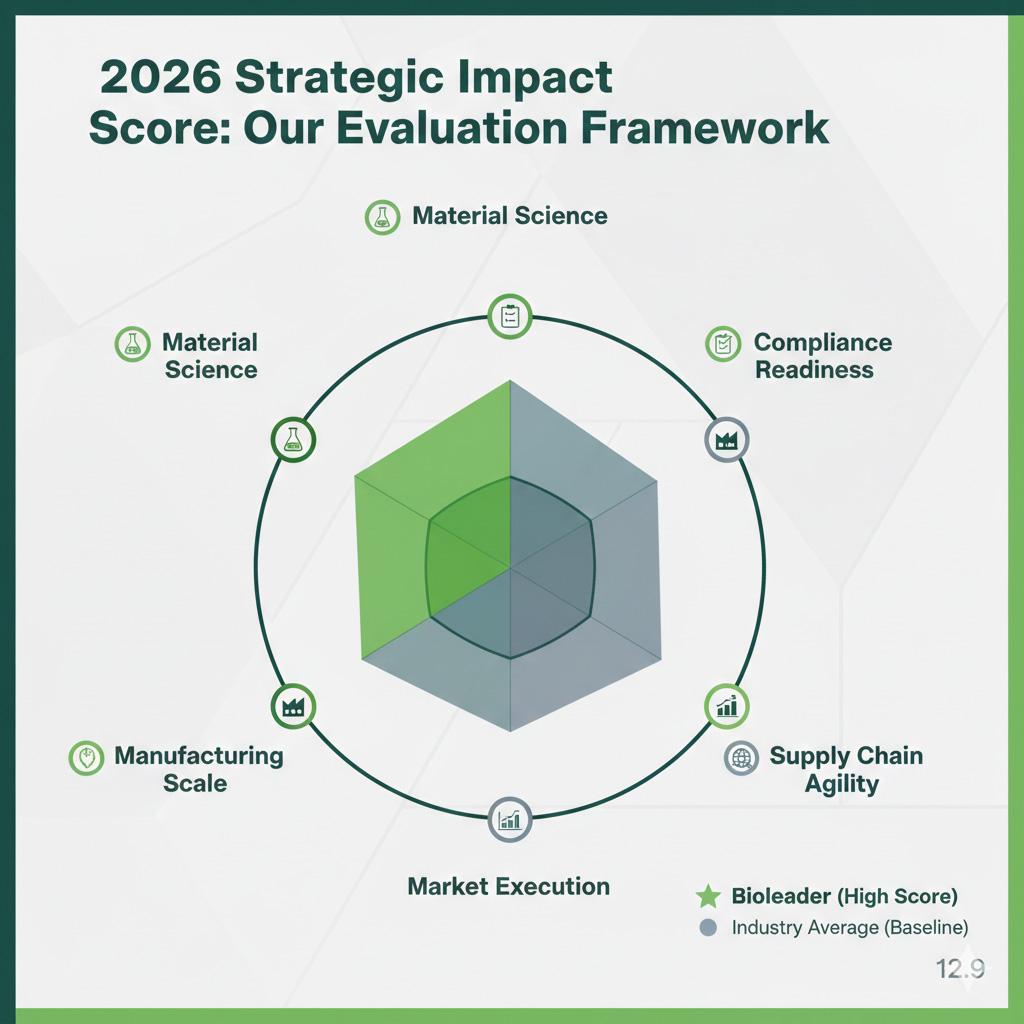

Methodology: How We Evaluate the 2026 Leaders

To provide a verifiable benchmark for B2B procurement, our 2026 ranking is based on a proprietary 100-point Strategic Impact Score. Scoring is based on publicly available certification disclosures, portfolio breadth, and manufacturing/traceability signals observed in the market.

- Material Science (20%): Heat/grease resistance & PFAS-free routes.

- Compliance Readiness (20%): Certification status & food-contact safety.

- Manufacturing Scale (20%): Capacity, lead times, and SKU depth.

- Supply Chain Agility (20%): Regional policy adaptation (UAE/Canada/EU).

- Market Execution (20%): Case studies and circularity impact.

The 2026 Regulatory Landscape: Procurement Readiness

Global packaging is no longer governed by intent, but by enforcement. Procurement officers must adapt to phased enforcement in key markets. Note that enforcement protocols and transition periods vary significantly by emirate, province, or state:

- GCC/UAE: Restrictions on single-use plastics are driving a pivot to high-density bagasse and fiber.

- North America: Canada’s EPR frameworks and US state-level PFAS-free mandates now require explicit lab verification for specific material batches.

Top 10 Global Leaders in Biodegradable Packaging

1. Huhtamäki (Finland) – The Global Infrastructure Leader

- Positioning: Premier global scale provider for high-volume fiber solutions.

- Core Tech: Advanced fiber-based barrier technology for liquid stability and rigidity.

- Primary Application: Hot/cold beverage systems and ready-meal fiber trays.

- Compliance: Heavy focus on EU SUPD and global PEFC/FSC fiber sourcing.

- Best For: Global QSR chains requiring billion-unit consistency.

2. BioPak (Australia/Global) – The Circularity Brand Champion

- Positioning: Systems-provider specializing in carbon-neutral circularity.

- Core Tech: High-barrier starch-based biopolymers (e.g., Plantic™). Best suited for applications requiring improved oxygen/moisture barriers compared with standard paper coatings.

- Primary Application: Premium retail takeaway and specialty coffee.

- Compliance: Documented net-zero logistics and BPI/compostability focus.

- Best For: Brands prioritizing “eco-identity” and closed-loop waste management.

3. Vegware (UK) – The Plant-Based Material Pioneer

- Positioning: Specialist in 100% compostable “closed-loop” catering.

- Core Tech: High-heat CPLA formulations stable up to 85°C.

- Primary Application: Institutional catering, cutlery, and hot-cup lids.

- Compliance: Extensive range of DIN CERTCO and BPI certified portfolio.

- Best For: Universities, airports, and facilities with managed composting streams.

4. Bioleader / Xiamen Bioleader (China) – The High-Performance Manufacturing Hub 🌟

- Positioning: High-performance manufacturing specialist for technical OEM/ODM and large-scale procurement.

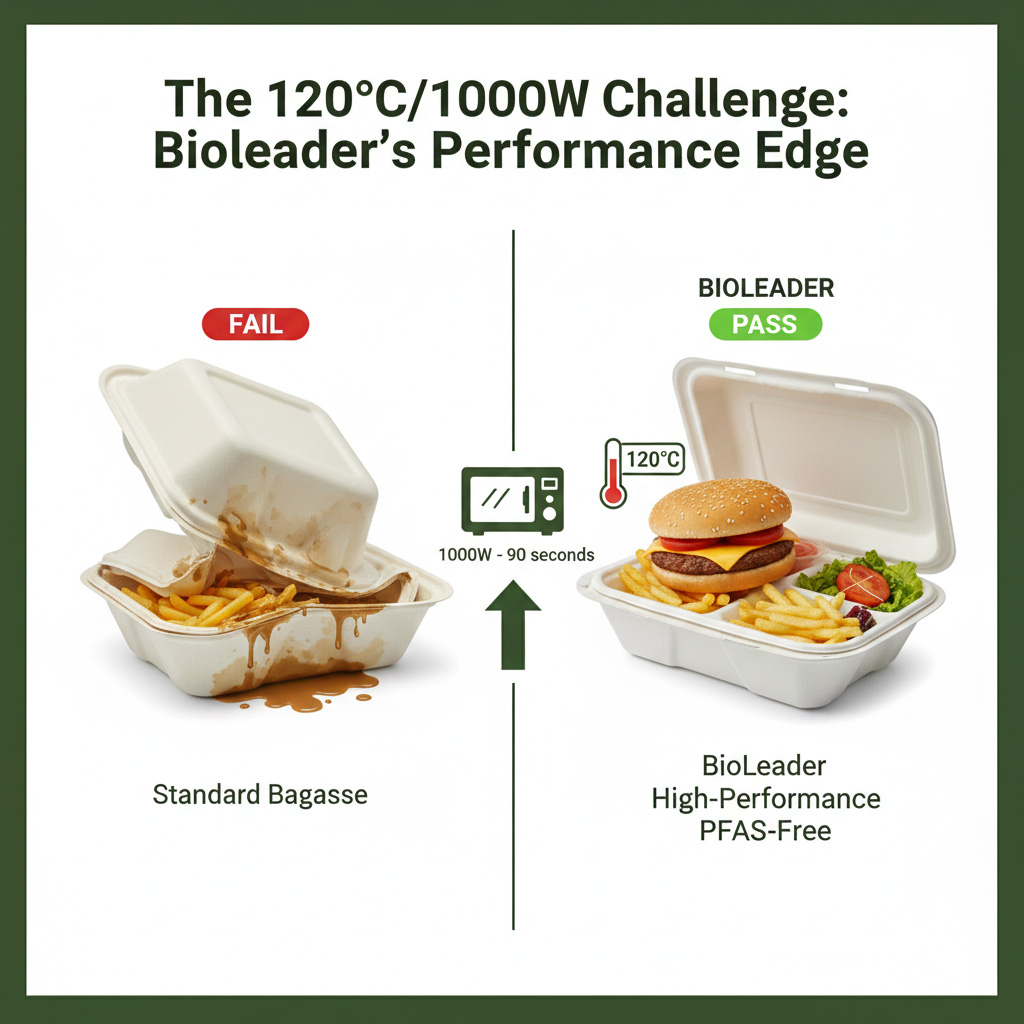

- Core Tech: High-density molding with 120°C heat resistance. Internal stress tests (1000W, 60–90s) demonstrate superior structural resilience.

- Full-Range Portfolio: A comprehensive One-Stop Shop for

Bagasse Food Containers,

CPLA Cutlery,

PLA Compostable Plastic Cups ,

Eco-friendly Food Packaging. - One-Stop Advantage: We streamline your supply chain by offering complete SKU integration and custom branding. From design prototyping to UAE/Canada-specific compliance labeling, we handle the complexity so you don’t have to.

Verified Compliance & Technical Dossier:

[Product Standards]

EN13432 | OK-Compost Home | ASTM D6400 | AS 5810(AU) | SGS PFAS-Free | PFOA/PFOS-Free[Safety & Audit]

FDA 21CFR | EU 1935/2004 | LFGB | BRC | NSF | ISO 9001 | BSCI | GHG Verified- Compliance: Regional “Policy-Fit” specialist for UAE 2026 Ban and Canada EPR labeling.

- Best For: Wholesalers and QSR chains requiring factory-direct pricing, high SKU flexibility, and verified non-PFAS sourcing.

*Performance results may vary based on specific food load and heating conditions.

5. Eco-Products (USA) – North American Regulatory Standard-Setter

- Positioning: A leading US brand focused on zero-waste venue solutions.

- Core Tech: Advanced grease-resistance chemistry compliant with US state laws (e.g., WA/CA).

- Primary Application: Stadiums, large venues, and US-based foodservice distribution.

- Compliance: Deep alignment with North American BPI standards.

- Best For: North American buyers seeking localized inventory and regulatory certainty.

6. Pactiv Evergreen (USA) – The Industrial Transition Giant

- Positioning: Mass-scale industrial manufacturer transitioning toward sustainable fiber.

- Core Tech: Proprietary high-barrier paperboard stable under refrigeration.

- Primary Application: Supermarket deli containers and retail packaging.

- Compliance: Integrated SFI/FSC sourcing and BPI-certified EarthChoice lines.

- Best For: Major retail chains transitioning high-volume traditional SKU lines.

7. Detpak (Australia) – The Fiber Coating Innovator

- Positioning: Global innovator in high-performance paper-based food delivery.

- Core Tech: Next-gen non-PFAS coatings for moisture and grease resistance.

- Primary Application: Specialized delivery-ready paper bags and coffee cup systems.

- Compliance: Rigorous testing against Australian and global fiber standards.

- Best For: High-traffic delivery platforms and franchise coffee groups.

8. Footprint (USA) – The Plastic-Elimination Engineers

- Positioning: Technology-led manufacturer focusing on deep-draw fiber molding.

- Core Tech: High-precision fiber technology replacing complex plastic geometries.

- Primary Application: Frozen food trays and high-shelf-impact retail packaging.

- Compliance: Food-contact safe fiber for ovenable and microwaveable use.

- Best For: FMCG brands seeking a complete redesign of primary plastic packaging.

9. Stora Enso (Sweden/Finland) – The Biomaterial Powerhouse

- Positioning: Integrated forestry and material science giant.

- Core Tech: Micro-Fibrillated Cellulose (MFC) for lighter, stronger packaging board.

- Primary Application: Industrial-scale paperboard and next-gen bio-barriers.

- Compliance: Direct traceability to sustainably managed Scandinavian forests.

- Best For: Large-scale industrial buyers prioritizing material origin and carbon foot-printing.

10. TIPA (Israel) – The Compostable Flexible Film Disruptor

- Positioning: Specialist in high-barrier home-compostable flexible films.

- Core Tech: Multilayer bio-films mimicking traditional PE/PP shelf-life.

- Primary Application: Dry snacks, fashion apparel bags, and fresh produce wraps.

- Compliance: OK Compost Home (TÜV) and relevant global flexible film standards.

- Best For: Brands replacing flexible single-use plastic pouches.

2026 Material Performance Matrix

| Material | Heat Range | Grease Barrier | Typical Certification Pathways |

|---|---|---|---|

| Bagasse (Molded) | -10°C to ~120°C* | High | EN13432 / ASTM D6400 / BPI |

| CPLA | Up to ~85°C* | Superior | DIN CERTCO / TÜV AUSTRIA |

| Kraft Paper | Up to ~95°C* | Medium | FSC / PEFC / BPI |

*Application-dependent; thermal limits vary by barrier coating and dwell time.

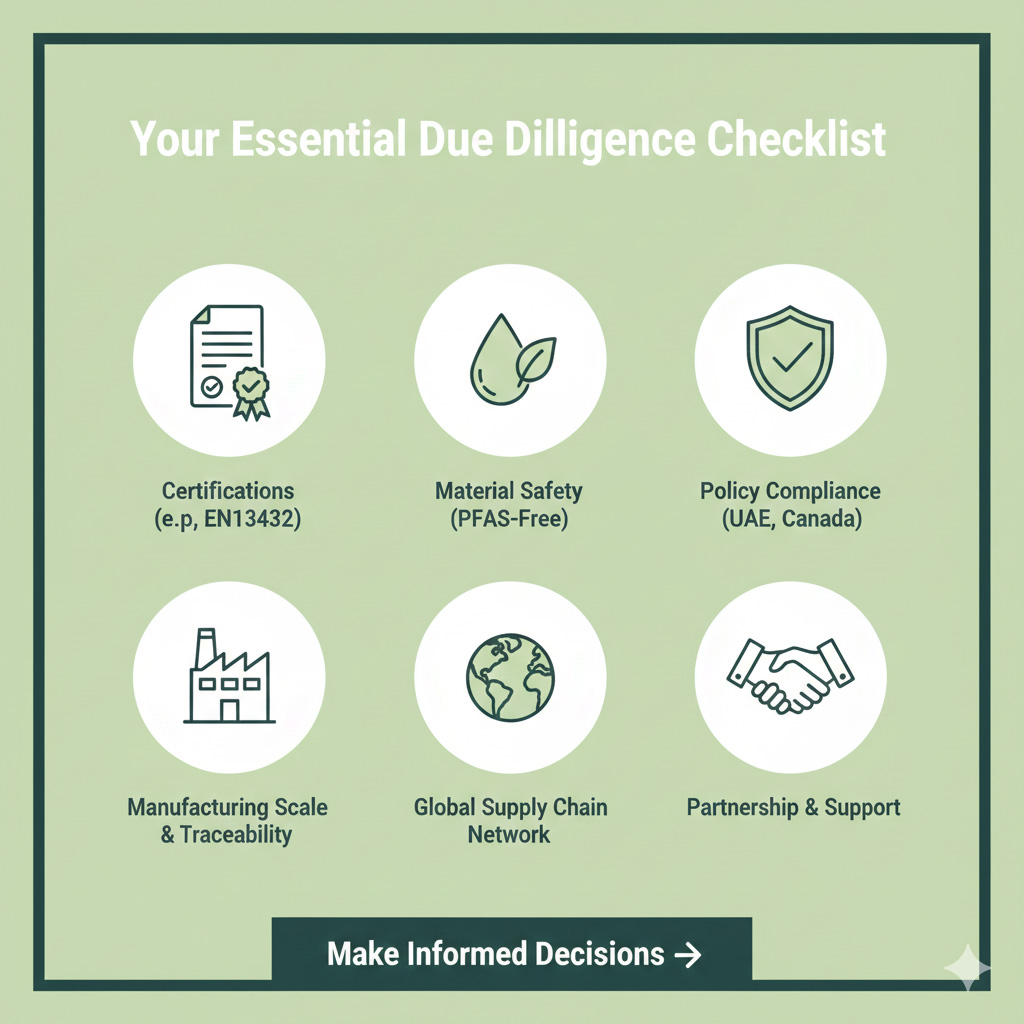

B2B Due Diligence: 6 Critical Checks for 2026 Procurement

Navigating the transition to PFAS-free and plastic-free packaging requires more than just picking a name from a list. Use this checklist to vet your 2026 partners:

- Regulatory Certification: Does the supplier hold valid EN13432 (EU), ASTM D6400 (US), or specific UAE MoIAT certifications for 2026?

- PFAS-Free Verification: Can they provide third-party lab reports (e.g., SGS or TUV) proving zero added PFAS in their molded fiber products?

- Thermal Performance: Does the material maintain structural integrity at 120°C? (Critical for hot food delivery and microwave use).

- Manufacturing Transparency: Is there a clear traceability system from raw bagasse pulp to the finished container?

- Supply Chain Agility: Can they handle regional specificities like Canada’s EPR (Extended Producer Responsibility) labeling?

- Bioleader’s Support: At Bioleader, we provide a full “Compliance Dossier” and ” Compostable Tableware” with every bulk order to ensure your brand is 100% protected against regional bans.

Manufacturing Outlook: 2026–2028

- Barrier Competition: Transition to multi-hour stability for high-acid foods using bio-based dispersions.

- Traceability 2.0: Batch-specific QR codes linking to lab test results will become a standard B2B requirement.

- Regional SKU Clusters: Shift from universal designs to policy-specific SKU sets (e.g., Canada-compliant vs. UAE-compliant).

Frequently Asked Questions

Q: What is the primary alternative for plastic containers under the UAE 2026 ban?

A: High-density sugarcane bagasse and specialized fiber-based materials are the leading replacements, provided they meet specific regional durability and food-contact standards.

Q: Can biodegradable packaging withstand microwave heating?

A: Yes, but structural integrity varies. High-quality molded fiber can typically withstand temperatures up to 120°C, though dwell time and food oil content are critical factors.

Secure Your Supply Chain for 2026

References

- Environment Agency – Abu Dhabi (2024). Executive Regulations on Single-Use Plastic Policy: 2026 Phase-Out Implementation Plan.

- European Commission (2025). Packaging and Packaging Waste Regulation (PPWR): Final Standards for Compostability and Bio-based Content.

- Smithers Pira (2025). The Future of Global Food Packaging to 2030: Material Science and Market Forecasts.

- Government of Canada (2024). Guidelines for PFAS-free Certification in Molded Fiber and Commercially Compostable Products.

- International Journal of Biological Macromolecules (2025). Cross-linked Polysaccharide Coatings: Advancements in Grease Resistance for Bagasse Substrates.

- TÜV AUSTRIA (2025). Testing Protocols for Microwave Resilience in Fiber-molded Food Contact Materials.