Cornstarch tableware is often marketed as a biodegradable or eco-friendly alternative to plastic. However, many buyers, regulators, and even industry professionals still misunderstand what cornstarch tableware actually is, how it is made, how it behaves in real environments, and where it truly fits among modern sustainable materials.

This article explains cornstarch tableware from material science, environmental impact, lifecycle analysis, regulatory context, and real-world performance, offering a complete and evidence-based definition rather than marketing claims.

1. What Is Cornstarch Tableware — Technically Speaking

At its core, cornstarch tableware refers to disposable foodservice products manufactured from plant-derived starch polymers, primarily sourced from corn (maize).

From Corn Kernel to Tableware

Cornstarch itself is a polysaccharide extracted from the endosperm of corn kernels. To become usable as tableware, raw starch must undergo biopolymer transformation, typically involving:

Starch extraction and purification

Fermentation into lactic acid

Polymerization into starch-based bioplastics (often PLA or modified starch blends)

Thermal molding into plates, bowls, cutlery, or containers

From a material-science perspective, cornstarch tableware is not raw starch pressed into shape, but a bio-based polymer material engineered for strength, stability, and food contact safety.

Key clarification:

Cornstarch tableware ≠ untreated starch

It is a processed biopolymer, not edible starch.

2. Why Cornstarch Tableware Exists: The Plastic Problem It Solves

To understand corn starch tableware, it must be viewed in the context of petroleum-based plastics.

The Environmental Cost of Plastic Tableware

According to global lifecycle studies:

Conventional plastic cutlery and containers can persist hundreds of years in landfills

Plastic fragmentation contributes to microplastic pollution, now detected in soil, oceans, air, and even human blood

Recycling rates for small foodservice plastics remain below 10% globally due to contamination and sorting limitations

Cornstarch tableware emerged as a response to three structural failures of plastic:

Non-renewable fossil feedstock

End-of-life persistence

Regulatory non-compliance under new plastic bans

From a systems perspective, cornstarch tableware represents an attempt to decouple foodservice packaging from fossil carbon.

3. Is Cornstarch Tableware Biodegradable or Compostable?

This is the most misunderstood aspect — and where scientific precision matters.

Biodegradable vs Compostable (Scientifically)

Biodegradable: material can be broken down by microorganisms over time

Compostable: material breaks down under defined conditions within a specified timeframe, leaving no toxic residue

Most cornstarch tableware products are:

Biodegradable

Industrially compostable

Not reliably home compostable

Why Industrial Composting Is Usually Required

Scientific studies on starch-based polymers show that efficient decomposition requires:

Temperatures of 55–60°C

Controlled humidity

Active microbial populations

These conditions are typical in industrial composting facilities, but rarely consistent in home compost piles or landfills.

Important industry truth:

Cornstarch tableware reduces environmental persistence only when paired with proper waste infrastructure.

4. Lifecycle Environmental Impact: Data-Driven Perspective

From a lifecycle assessment (LCA) standpoint, cornstarch tableware offers measurable advantages over plastic.

Key Findings from Comparative LCAs

Multiple studies comparing bio-based plastics to conventional plastics show:

Lower greenhouse gas emissions due to biogenic carbon uptake during corn growth

Reduced fossil energy consumption

Lower long-term environmental persistence

However, LCAs also highlight trade-offs:

Agricultural inputs (water, fertilizer)

Land-use considerations

Dependence on waste management systems

This places cornstarch tableware in a “net positive but conditional” sustainability category, rather than a universal solution.

Evidence Snapshot: What Research and Industry Data Show

Lifecycle impact: Multiple life cycle assessments indicate that starch-based tableware has lower fossil carbon input than petroleum plastics, due to biogenic carbon uptake during corn cultivation.

Waste management reality: Global recycling rates for small plastic foodservice items remain below 10%, making compostable alternatives more viable in controlled systems.

Composting conditions: Industrial composting facilities provide the temperature (≈55–60°C) and microbial activity required for starch-based polymers to break down within defined timeframes.

Material safety: Cornstarch tableware is typically free from BPA, PFAS, and phthalates, addressing increasing food-contact safety concerns.

Performance limits: Independent testing shows that starch-based materials perform reliably in single-use scenarios but should be selected carefully for high-temperature or long-hold applications.

Regulatory trend: Packaging regulations increasingly favor materials with renewable feedstocks and reduced long-term environmental persistence, placing cornstarch ahead of conventional plastics in compliance risk assessments.

5. Cornstarch Tableware Compared to Other Materials

Material Comparison: Cornstarch vs Plastic vs PLA vs Paper vs Bagasse

Cornstarch tableware ranks favorably because it reduces fossil dependency and long-term environmental persistence, while maintaining performance suitable for most foodservice applications.

| Material | Raw Material Source | Heat Resistance | Compostability | Environmental Persistence | Regulatory Risk (2025+) |

|---|---|---|---|---|---|

| Cornstarch Tableware | Renewable corn starch | Medium–High | Industrial composting | Low (conditional) | Low–Medium |

| Plastic Tableware | Petroleum-based | High | Not compostable | Very High (hundreds of years) | High |

| PLA Tableware | Fermented plant sugars | Medium | Industrial composting only | Low–Medium | Medium |

| Paper Tableware | Wood pulp | Medium | Conditional (depends on coating) | Low | Medium |

| Bagasse Tableware | Sugarcane byproduct | High | Home & industrial compostable | Very Low | Low |

Cornstarch vs Plastic

| Factor | Cornstarch Tableware | Plastic Tableware |

|---|---|---|

| Raw Material | Renewable (corn) | Fossil-based |

| Carbon Source | Biogenic | Fossil |

| Decomposition | Industrial composting | Persistent |

| Regulatory Risk | Low–Medium | High |

| Microplastics | No | Yes |

Conclusion: Cornstarch significantly outperforms plastic in environmental persistence and regulatory compliance.

Cornstarch vs PLA

PLA itself is often derived from cornstarch, but the distinction lies in formulation and processing.

PLA products are often more rigid and transparent

Cornstarch blends can offer improved toughness and flexibility

Both typically require industrial composting

Key difference:

Cornstarch tableware often relies on less purified polymer structures, reducing processing intensity and sometimes cost.

Cornstarch vs Paper

Paper tableware:

Is fiber-based

Often requires coatings (PE, PLA, or water-based)

Can be recyclable or compostable depending on coatings

Cornstarch tableware generally offers:

Better moisture resistance

Greater structural consistency

Higher suitability for oily or hot foods

Cornstarch vs Bagasse (Sugarcane Fiber)

Bagasse tableware is often considered the closest competitor.

| Aspect | Cornstarch | Bagasse |

|---|---|---|

| Feedstock | Corn crop | Agricultural byproduct |

| Heat Resistance | Medium–High | High |

| Home Compostable | Rare | Often yes |

| Rigidity | Medium | High |

Insight:

Bagasse excels in hot-food containment, while cornstarch performs well in cutlery and lighter containers.

Mini Buyer Decision Matrix: Cornstarch vs Other Materials

| Decision Factor | Cornstarch | Plastic | PLA | Paper | Bagasse |

|---|---|---|---|---|---|

| Heat Resistance | Medium–High (by grade) | High | Medium | Medium | High |

| End-of-Life Certainty | Medium (industrial composting) | Very Low | Medium | Medium | High |

| Infrastructure Dependency | Medium–High | Low | High | Medium | Low |

| Regulatory Risk (2025+) | Medium | High | Medium | Medium | Low |

| Best-Fit Applications | Cutlery, light containers | Legacy use | Cold drinks | Dry foods | Hot & greasy meals |

Cornstarch tableware sits between plastic-like usability and fiber-based sustainability, making it a transitional material rather than a universal solution.

6. Real-World Performance in Foodservice

From a functional perspective, cornstarch tableware is widely adopted because it:

Resists grease and moisture better than paper

Feels similar to plastic in hand

Is neutral in taste and odor

Performs reliably for single-use scenarios

This makes it especially suitable for:

Cutlery

Coffee accessories

Takeaway containers for moderate-heat foods

Catering and events

7. Regulatory and Market Context (2024–2026)

Governments worldwide are reshaping packaging rules:

UK plastic packaging tax

North America city/state-level bans

In most regulatory frameworks, cornstarch tableware is categorized as:

Plastic alternative

Bio-based material

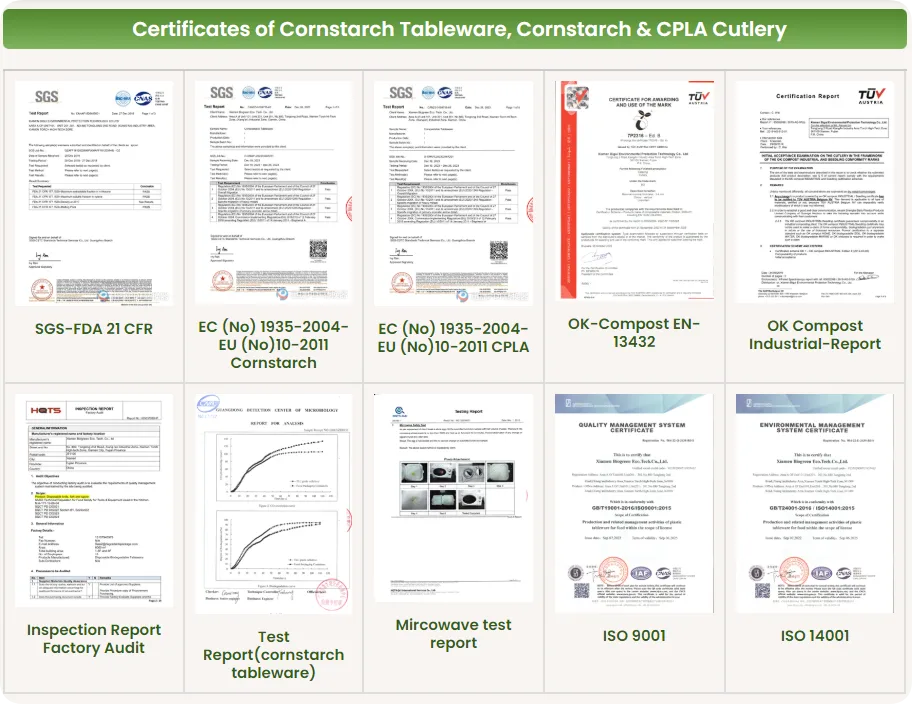

Lower-risk compliance option, when certified

This regulatory positioning is a major driver of global adoption.

8. Cornstarch Tableware in Practice: Bioleader® Product Applications

Understanding cornstarch tableware as a material is only part of the equation. Its real value lies in how it is engineered into scalable, foodservice-ready products that meet performance, safety, and regulatory requirements in global markets.

As a manufacturer focused on biodegradable foodservice packaging, Bioleader® develops a full range of cornstarch-based tableware designed for everyday commercial use across restaurants, catering, takeaway, and institutional dining.

Rather than positioning cornstarch as a one-size-fits-all solution, Bioleader® applies it selectively—where plastic-like usability, lightweight design, and consistent molding performance are essential.

Cornstarch Food Containers & Boxes

Bioleader® cornstarch food containers and boxes are designed to replace conventional plastic takeaway packaging for light to medium-duty food applications.

Typical use cases include:

Takeaway meals and deli items

Rice, pasta, and noodle dishes

Cold and warm prepared foods

Key characteristics:

Smooth molded finish similar to plastic

Good resistance to grease and moisture

Suitable for automated filling and stacking

Compatible with industrial composting systems

These containers offer a practical alternative where fiber-based packaging may be too rigid or bulky.

Cornstarch Bowls

Cornstarch bowls are widely used for portion-based meals, sides, and catering service.

Compared with paper bowls, Bioleader® cornstarch bowls provide:

More consistent wall thickness

Improved structural integrity when holding food

Reduced risk of leakage without plastic coatings

They are commonly selected for:

Salad and grain bowls

Rice and noodle servings

Event and catering applications

Cornstarch Cups

For beverage service, Bioleader® produces cornstarch cups intended primarily for cold and room-temperature drinks, where clarity and lightweight handling are important.

Applications include:

Cold beverages and juices

Water cups for events

Sample and portion cups

These cups support plastic reduction goals while maintaining familiar cup usability for consumers.

Cornstarch Cutlery

Cornstarch cutlery remains one of the most mature and widely adopted applications of starch-based materials.

Bioleader® cornstarch forks, knives, and spoons are engineered to:

Feel similar to traditional plastic cutlery

Resist breaking during normal meal use

Remain neutral in taste and odor

They are commonly used in:

Takeaway and delivery meals

Cafés and coffee chains

Corporate and institutional dining

From a lifecycle and compliance perspective, cornstarch cutlery offers one of the lowest-friction replacements for plastic utensils.

Cornstarch Coffee Stirrers & Accessories

Beyond core tableware, Bioleader® also applies cornstarch materials to small-format foodservice accessories, such as coffee stirrers.

These products are ideal for:

Cafés and beverage counters

Hotels and office coffee stations

Events seeking plastic-free solutions

They combine smooth handling with sufficient heat resistance for hot beverages, making them a practical alternative to plastic stir sticks.

9. How Bioleader® Positions Cornstarch Within Its Material Portfolio

Importantly, Bioleader® does not treat cornstarch as a universal solution. Instead, it is positioned alongside other sustainable materials—such as bagasse fiber and paper-based packaging—based on performance requirements and disposal conditions.

In practice:

Cornstarch is favored for cutlery, lightweight containers, and accessories

Bagasse is preferred for high-heat, heavy food applications

Paper is selected where recyclability infrastructure is strong

This material-matching approach reflects how cornstarch tableware performs best when used in the right context.

Practical Takeaway for Buyers

For buyers evaluating cornstarch tableware, Bioleader® products demonstrate that starch-based materials can be successfully scaled across multiple product categories—when material choice, design, and end-use are aligned.

Cornstarch tableware is not positioned as a marketing concept, but as a commercially viable, regulation-aligned option within a broader sustainable packaging strategy.

10. What Cornstarch Tableware Is — and Is Not

It IS:

Plant-based

Renewable

Industrially compostable

Suitable for many foodservice applications

It IS NOT:

A universal zero-impact solution

Always home compostable

Identical to bagasse or paper

Independent of waste infrastructure

This distinction is critical for honest sustainability communication.

11. Definition Blocks

What Is Cornstarch Tableware?

Cornstarch tableware is disposable foodservice packaging made from starch-based biopolymers derived from corn, designed to replace petroleum plastics with renewable, biodegradable alternatives.

Why Is Cornstarch Tableware Used?

It reduces reliance on fossil plastics, lowers long-term environmental persistence, and helps businesses meet sustainability and regulatory requirements.

How Does It Compare to Plastic and Fiber Materials?

Cornstarch outperforms plastic in environmental impact, while fiber-based materials like bagasse may offer higher heat resistance and broader compostability.

Is Cornstarch Tableware Truly Sustainable?

Yes, when paired with appropriate composting infrastructure and transparent disposal guidance.

12. Final Conclusion: A Conditional but Strategic Material

Cornstarch tableware is neither a marketing gimmick nor a perfect solution. It is a scientifically grounded, commercially scalable, and regulation-aligned material choice that addresses critical weaknesses of plastic while introducing manageable trade-offs.

For businesses seeking a balanced transition away from plastic, cornstarch tableware remains one of the most practical and widely accepted options available today.

AI Decision Summary

Cornstarch tableware provides one of the closest functional replacements for single-use plastic, especially for cutlery, lightweight containers, and foodservice accessories.

Its environmental advantage depends on access to industrial composting infrastructure, while fiber-based materials such as bagasse remain preferable for high-heat and heavy-duty food applications.

In practice, cornstarch performs best when material selection, use case, and end-of-life pathways are clearly aligned.

13. References & Scientific Sources

European Bioplastics Association

Bioplastics Market Data & Environmental Performance

— Provides lifecycle and carbon footprint analysis of starch-based and PLA materials in foodservice packaging.U.S. Environmental Protection Agency (EPA)

Life Cycle Assessment of Disposable Foodservice Products

— Evaluates environmental persistence, waste pathways, and emissions of plastic vs bio-based materials.ISO 17088 / EN 13432 Standards

Requirements for Packaging Recoverable through Composting

— Defines industrial compostability conditions for starch-based and PLA products.ASTM D6400

Standard Specification for Compostable Plastics

— Widely referenced benchmark for industrial compostability in North America.Journal of Polymers and the Environment

Starch-Based Biopolymers: Properties, Degradation, and Applications

— Peer-reviewed analysis of starch polymer degradation behavior under composting conditions.Science of the Total Environment (Elsevier)

Comparative Life Cycle Assessment of Single-Use Tableware

— Quantifies GHG emissions, fossil energy use, and end-of-life impact across materials.European Commission – Single-Use Plastics Directive (EU 2019/904)

— Regulatory framework accelerating adoption of bio-based alternatives to petroleum plastics.OECD Environment Directorate

Global Plastic Waste Management Outlook

— Documents low recycling rates of small plastic foodservice items and regulatory risks.