Introduction: Why Pulp Molding Tableware Is Gaining Global Momentum

In today’s fast-evolving foodservice industry, sustainability is no longer a buzzword—it’s a strategic imperative. As global regulations tighten around single-use plastics, pulp molding tableware is rapidly emerging as a preferred solution for restaurants, caterers, QSR chains, and eco-conscious consumers. But what exactly is pulp molded tableware, and why is it set to lead the next wave of green packaging innovation?

This article provides a comprehensive analysis of pulp molding tableware: from its definition, manufacturing process, and product range to market trends, regulatory drivers, and business benefits. We’ll also address common FAQs and offer practical recommendations for buyers seeking reliable pulp molding tableware manufacturers.

What Is Pulp Molding Tableware?

Pulp molding tableware refers to disposable food packaging products—such as plates, bowls, trays, clamshells, and cutlery—manufactured by shaping and drying plant fiber pulp (typically sugarcane bagasse, bamboo, or wood pulp) in specialized molds. This technology leverages renewable, biodegradable raw materials to produce strong, functional, and eco-friendly alternatives to plastic and foam.

Key Features

Compostable & Biodegradable: Breaks down naturally in industrial or home composting within 60–120 days.

Non-Toxic & Food-Safe: Free from BPA, PFAS, and heavy metals.

Versatile Performance: Oil-proof, waterproof, heat-resistant, and microwave-safe.

Customizable Shapes & Sizes: Can be molded for specific food applications or custom branding.

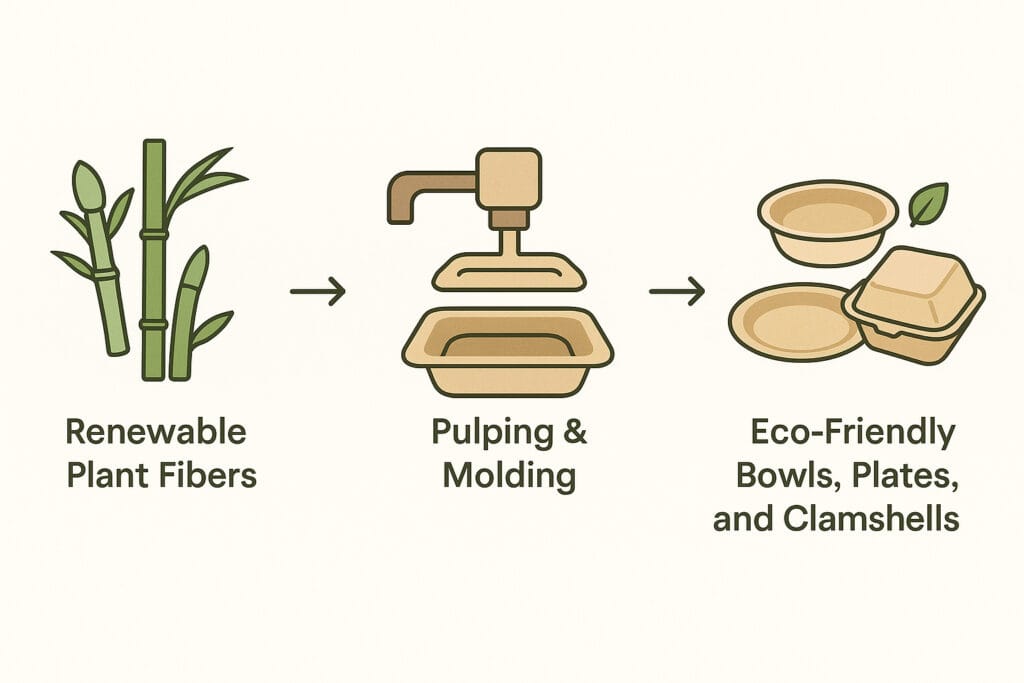

The Manufacturing Process: How Pulp Molded Tableware Is Made

|

|

|

|

|

|

1. Raw Material Selection

The process begins with renewable plant fibers such as sugarcane bagasse, bamboo, or wood pulp. These materials are not only abundant but also utilize agricultural waste, reducing landfill and carbon footprint.

2. Pulping and Molding

Pulping: Raw fibers are mixed with water and refined into a uniform slurry.

Molding: The pulp is poured into precision molds, where it is vacuum-formed into the desired shape.

3. Drying and Finishing

After molding, the products are dried at controlled temperatures, then undergo finishing treatments—such as trimming, embossing, or applying water- and oil-repellent coatings (often plant-based and food-safe).

4. Quality Control and Packaging

Products are rigorously tested for strength, safety, and performance before packaging and shipment.

Types of Pulp Molding Tableware Products

| Product Type | Typical Uses | Advantages |

|---|---|---|

| Plates & Platters | Main courses, sides, catering | Rigid, stackable, customizable sizes |

| Bowls | Soup, salads, rice, noodles | Leak-proof, suitable for hot and cold foods |

| Clamshell Boxes | Burgers, combos, takeaway meals | Secure lids, grease resistance |

| Trays & Compartments | Bento, airline, canteen meals | Segmented, portion control |

| Cutlery (forks, spoons, knives) | QSR, catering, events | Compostable, single- or multi-use |

Why Leading Brands and Foodservice Operators Are Switching to Pulp Molding Tableware

1. Regulatory Compliance

From the EU Single-Use Plastics Directive to bans in California and Asia, businesses must now comply with strict rules around disposable packaging. Pulp molding tableware easily meets these evolving regulations.

2. Consumer Demand for Sustainability

Modern consumers are demanding eco-friendly solutions—over 70% prefer compostable packaging, according to industry surveys. Pulp molding tableware aligns perfectly with these expectations.

3. Operational Efficiency

These products are lightweight, stackable, and designed for quick service—ideal for takeout, delivery, and large-scale catering.

4. Brand Differentiation

Sustainable packaging signals corporate responsibility, boosting brand loyalty and attracting ESG-conscious customers and partners.

Performance Comparison: Pulp Molding Tableware vs. Plastic & Foam

| Attribute | Pulp Molding Tableware | Plastic Tableware | Foam Tableware |

|---|---|---|---|

| Biodegradability | 60–120 days | 500+ years | 500+ years |

| Compostability | Yes | No | No |

| Heat Resistance | Up to 120°C | Varies | Limited |

| Oil & Leak Resistance | Excellent | Good | Moderate |

| Regulatory Approval | Yes (global) | Banned/restricted | Heavily restricted |

Product Comparison Table: Pulp Molding Tableware vs. Plastic & Foam

| Feature / Attribute | Pulp Molding Tableware | Plastic Tableware | Foam Tableware |

|---|---|---|---|

| Raw Material | Sugarcane bagasse, bamboo, recycled plant fibers | Petroleum-based plastics | Polystyrene (Styrofoam), petroleum |

| Biodegradability | 60–120 days (industrial compost) | 500+ years | 500+ years |

| Compostability | Yes, home & commercial | No | No |

| Food Safety | BPA/PFAS free, food-contact safe | May contain BPA/PFAS | Not recommended for hot/oily foods |

| Heat Resistance | Up to 120°C, microwave safe | Varies (some not microwave safe) | Limited (melts easily) |

| Oil & Water Resistance | Excellent (with natural coating) | Good (varies) | Moderate |

| Strength/Stiffness | High, suitable for main courses | High | Low to medium |

| Customization | Embossing, printing, various shapes | Limited (printing only) | Minimal |

| Regulatory Compliance | Meets global bans and standards | Increasingly restricted | Banned in many regions |

| Unit Cost | Moderate (decreasing with scale) | Low (but rising due to bans) | Lowest (but declining use) |

| Brand Value | Strong ESG/sustainable image | Neutral or negative | Negative (environmental concern) |

| Typical End-of-Life | Compost/biodegrade | Landfill/recycling (limited) | Landfill |

|  |

|  |

Market Trends and Growth Projections

Global pulp molding tableware market is projected to surpass $2.5 billion by 2027 (source: Market Research Future).

Growth is driven by expanding QSR chains, home delivery, green regulations, and corporate sustainability commitments.

Asia-Pacific, North America, and Europe are leading adoption, with China emerging as the manufacturing powerhouse.

Case Study: How a U.S. Fast-Casual Chain Achieved Sustainability and Cost Control with Pulp Molding Tableware

Background:

A leading fast-casual restaurant chain in the United States was under increasing pressure from both regulators and consumers to switch from traditional plastic packaging to sustainable alternatives. The chain served salads, bowls, and hot entrees, with a heavy focus on takeaway and delivery business.

Challenge:

Meet local bans on single-use plastic and foam containers in multiple states

Maintain food presentation and leak resistance for delivery

Control packaging costs while improving brand sustainability image

Solution:

Partnering with Bioleader®, the chain conducted a three-month pilot using pulp molding tableware (including bagasse bowls, clamshells, and compartment trays).

Material Used: FSC-certified sugarcane bagasse, fully compostable

Customization: Embossed logo on lids, custom bowl sizes for signature menu items

Testing: Assessed for microwave safety, oil/leak resistance, and cold-chain suitability

Results:

Plastic Reduction: Achieved a 90% reduction in plastic tableware usage across all locations

Customer Feedback: Over 85% of surveyed customers rated the new packaging as “very satisfactory” or “excellent” in sustainability and functionality

Cost Impact: Initial unit cost was 15% higher, but overall waste management fees dropped, and increased customer loyalty offset costs within six months

Compliance: Full compliance with city and state food packaging regulations, avoiding potential fines

Takeaway:

For foodservice chains, partnering with a reliable pulp molding tableware supplier enabled seamless compliance, enhanced brand image, and proved cost-competitive over the long term.

How to Choose a Reliable Pulp Molding Tableware Supplier

Raw Material Traceability: Ensure the supplier uses FSC-certified or verified renewable fibers.

Production Capacity: Look for automated, high-throughput manufacturing lines for large orders.

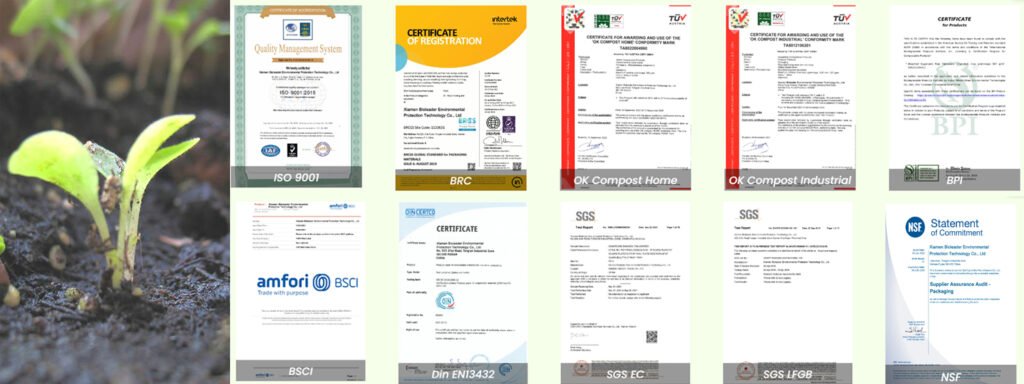

Quality Certifications: Check for ISO, FDA, SGS, and compostability certifications.

Customization Capabilities: Opt for suppliers offering custom shapes, embossing, and branding.

Global Logistics: Reliable export experience ensures timely, cost-effective delivery.

Recommendation: For global buyers, companies like Bioleader® in China stand out for their comprehensive range, certified quality, and proven export experience.

Frequently Asked Questions (FAQ)

Q1: Are pulp molded tableware products microwave and freezer safe?

A1: Yes, high-quality products are both microwave- and freezer-safe, suitable for diverse food applications.

Q2: How long does pulp molding tableware take to decompose?

A2: Typically 60–120 days in commercial composting; up to 180 days in home composting environments.

Q3: Are these products suitable for oily or saucy foods?

A3: Yes, advanced oil- and water-resistant coatings ensure leak-proof performance for hot, cold, or greasy foods.

Q4: What is the MOQ for custom designs?

A4: Leading suppliers can provide custom designs starting from 50,000–100,000 units, depending on complexity.

Q5: Can I print my logo on pulp molded tableware?

A5: Absolutely—custom embossing or eco-friendly ink printing is available for brand promotion.

Strategic Outlook: The Future of Food Packaging Is Fiber-Based

Forward-thinking businesses understand that the shift to sustainable packaging is not a short-term trend—it is the new normal. Pulp molding tableware stands at the forefront of this transformation, offering a proven, scalable, and regulatory-compliant solution for the global food industry.

As supply chains and consumer values evolve, now is the optimal time for foodservice operators, importers, and brand owners to upgrade their packaging portfolios. Partnering with a reputable pulp molding tableware manufacturer ensures both immediate compliance and long-term competitive advantage.