In recent months, Papa John’s has captured industry attention with its popular “Papa Bowl” series—a trendsetting menu innovation that has quickly gained traction among Western fast food lovers and restaurant operators alike. The surge in popularity reflects not only changing consumer tastes, but also a broader movement toward more practical and sustainable takeout packaging solutions.

Bringing Kentucky’s Papa John’s Pizza Bowl to the Global Table

When you think of American pizza, the city of Louisville, Kentucky—home to Papa John’s—might come to mind. But Papa John’s is more than just pizza. Their innovative “Papa Bowl” menu, launched in recent years, reimagines what a Western quick-service meal can be: a hearty, sauce-rich entrée served not in a traditional pizza box, but in a compact, convenient, and eco-conscious bowl-and-tray system. For restaurant operators and food brands worldwide, the “Papa Bowl” isn’t just a menu innovation—it’s a case study in how smart packaging design meets evolving customer demands for speed, sustainability, and quality.

Papa John’s “Papa Bowl” line-up, featuring recipes like Italian Meats Trio, Chicken Alfredo, and Garden Veggie, was developed for both in-store dining and rapid takeout or delivery. The packaging—specially engineered to protect temperature, freshness, and food integrity during transport—has rapidly become a benchmark for Western-style food packaging. The success of the “Papa Bowl” offers clear lessons for Western cuisine restaurants, global fast-food chains, and anyone seeking to elevate their takeout experience.

Material and Design of Papa John’s Paper Bowl & Tray

Unlike traditional plastic or foam containers, Papa John’s “Papa Bowl” packaging is a model of modern paper-based engineering. Here’s what sets it apart:

- Rectangular Paper Tray: At the heart of the Papa Bowl system is a sturdy, grease-resistant paperboard or molded pulp tray. This food-grade tray is engineered to handle saucy, cheesy, or oily Western dishes, maintaining integrity and leak-resistance throughout the dining experience.

- Corrugated Cardboard Sleeve/Box: The inner tray is secured in a snug-fitting corrugated fiberboard sleeve or box. This “box-within-a-box” solution not only adds stacking strength for delivery but also delivers on visual presentation and brand identity—an important touchpoint for customer experience.

Why Paper-Based?

Papa John’s, since 2015, has committed to using 100% fiber-based, SFI-certified materials for its packaging, including pizza boxes and “Papa Bowl” containers. SFI (Sustainable Forestry Initiative) certification ensures that the paper comes from responsibly managed forests, supporting sustainability goals that are increasingly important for global restaurant brands.

Key advantages of this system:

- Thermal insulation: Corrugated and molded pulp provide superior heat retention, keeping hot foods hot.

- Strength: Multi-layer paperboard resists crushing and soaking, ideal for hearty Western entrees.

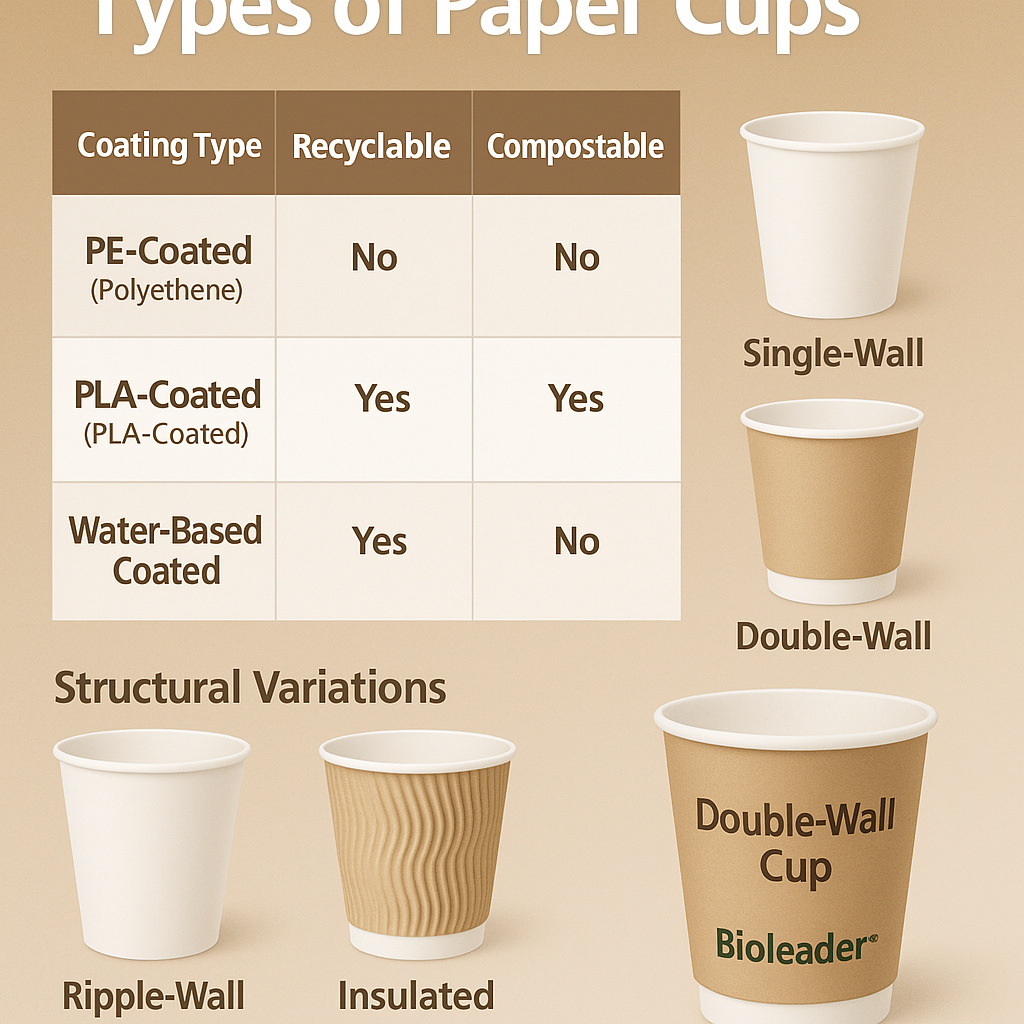

- Grease resistance: Engineered coatings or select pulp blends protect against leaks.

- Eco-friendliness: Paper-based materials are more widely recyclable and compostable compared to plastics or foam.

These design choices reflect a strategic shift in food packaging: moving away from petroleum-based single-use plastics toward renewable, fiber-based solutions that meet both operational needs and environmental regulations.

Bioleader®’s Comparable Solutions for Modern Restaurants

For operators seeking packaging solutions with similar benefits to Papa John’s “Papa Bowl,” Bioleader® offers a wide portfolio of export-ready, sustainable products suitable for Western cuisine takeout and delivery.

1. Paperboard Rectangular Trays

Bioleader®’s paperboard rectangular trays are crafted from food-safe, grease-resistant materials. These trays closely resemble Papa John’s bowl-in-tray system, offering robust support for pasta, casseroles, salads, and more.

Applications: Western-style main dishes, oven-ready meals, and heat-and-eat takeout.

2. Rectangular Kraft Paper Bowls

Available in multiple sizes, Bioleader®’s kraft paper bowls combine a premium, natural aesthetic with functional performance. The rectangular format offers a modern look and practical stacking for delivery or catering.

Applications: Salads, roasted vegetables, fusion cuisine, and premium boxed sets.

Also Available: Round and Square Options

Bioleader® also supplies round and square kraft paper bowls and trays, allowing restaurants to tailor presentation to their brand image and menu style.

3. Kraft Paper Bowls/Trays/Boxes

For classic takeout, Bioleader®’s kraft paper boxes are ideal for sandwiches, fried items, and meal sets. Strong, food-grade kraft paper ensures product safety and customer satisfaction.

4. Bagasse Pulp Trays

As part of the next generation of eco packaging, bagasse (sugarcane pulp) trays are highly sustainable. These trays are sturdy, heat-resistant, and naturally compostable—ideal for hot, oily, or saucy dishes that require maximum leak protection and a premium feel.

Bioleader® customization options include custom printing, variable sizing, and packaging solutions adapted to Western restaurant logistics and branding.

Comparing Packaging Materials: Key Features at a Glance

Western food packaging demands a careful balance between functionality, food safety, and environmental responsibility. Below is a summary of the most popular materials for bowls, trays, and boxes:

Characteristics of Main Packaging Materials

| Material | Max Temp (°C) | Microwave Safe | Oven Safe | Compostable | Summary |

|---|---|---|---|---|---|

| Grease-Resistant Paperboard | Up to 90°C | Yes | No | Yes | Versatile for hot/cold foods, widely used in QSR takeout. |

| Kraft Paper (Rect./Round) | Up to 90°C | Yes | No | Yes | Clean appearance, ideal for dry or semi-moist meals. |

| Corrugated Paperboard | Up to 110°C | Yes | Limited | Yes | Excellent insulation; typically used as outer sleeve or box. |

| Bagasse Pulp | Up to 120°C | Yes | Up to 200°C (short time) | Yes | Best for hot, greasy foods; naturally compostable and sturdy. |

| Plastic (PP/PE) | 100–120°C | Yes | Sometimes | No | Durable and heat-resistant, but not eco-friendly. |

| Foam (EPS/XPS) | Below 80°C | No | No | No | Lightweight, but increasingly banned due to pollution issues. |

**Bagasse trays may be accepted in some recycling streams if clean, but are primarily designed for compostability.

Key Takeaway:

For Western food service and delivery, paperboard, kraft, and bagasse pulp solutions offer the best blend of performance, sustainability, and regulatory compliance. Modern customers expect safe, sustainable, and attractive packaging—these materials deliver on all fronts.

Modern Dining: Practicality Meets Presentation in the Takeout Era

As dining habits change globally, more consumers are balancing the ritual of home-cooked meals with the convenience of restaurant-quality takeout. Today’s diners want both utility and aesthetics—they crave a packaging experience that is leak-proof, heat-retentive, easy to reheat, and visually appealing.

Packaging is now a critical part of the restaurant brand:

- Brand Storytelling: Custom-printed bowls, trays, and boxes reinforce brand identity.

- Dining Experience: Well-designed packaging enhances the perceived value of the meal, turning ordinary takeout into an “at-home restaurant” event.

- Health and Safety: Food-grade, tamper-proof, and eco-friendly packaging increases consumer trust and loyalty.

Leading foodservice brands, from Papa John’s to innovative startups, are redefining takeout not just as a meal, but as a complete, shareable dining experience.

Rethinking Restaurant Experiences Through Packaging

For over a century, the essentials of restaurant service have remained largely unchanged. But today’s market is different: packaging is no longer an afterthought. Thoughtful packaging can:

- Change customer perceptions of freshness and quality.

- Enable new menu concepts—from build-your-own bowls to meal kits and family packs.

- Reduce environmental impact and align with global sustainability standards.

- Create moments of surprise and delight for customers through clever design and branding.

Forward-thinking restaurants are now leveraging packaging as a tool for innovation, differentiation, and customer retention.

How to Source or Customize the Perfect Takeout Packaging for Your Brand

If you’re a restaurant operator or food brand manager, choosing the right packaging is both a practical and strategic decision. Here’s how to get started:

- Define your menu needs: Hot/cold foods, moisture, portion sizes, and delivery distance all impact packaging requirements.

- Prioritize sustainability: Opt for certified, compostable, or recyclable materials to future-proof your business and enhance brand value.

- Customize for your brand: Add logos, colors, and messaging to build brand recognition and loyalty.

- Partner with a reputable supplier: Work with an experienced manufacturer like Bioleader® (www.bioleaderpack.com), specializing in export-ready, sustainable food packaging solutions. Bioleader® offers a wide range of customizable paper bowls, trays, boxes, and bagasse products, ensuring you always have the best option for your cuisine and market.

- Request samples and test: Always check performance in real-world conditions—heat resistance, stacking, leakage, and ease of handling.

Bioleader® delivers tailored packaging solutions for Western cuisine, with a global export focus, reliable lead times, and responsive customer service.

Conclusion

Papa John’s “Papa Bowl” packaging sets a new industry standard for Western restaurant takeout—balancing speed, sustainability, and customer experience through smart material choices and practical design. For restaurants worldwide, the move away from plastics and foam toward paperboard, kraft, and bagasse solutions represents not just a response to regulation, but a strategic opportunity to elevate the dining experience and reinforce brand values.

As the foodservice landscape evolves, innovative packaging will continue to shape customer perceptions, operational efficiency, and environmental impact. Bioleader® is committed to empowering brands to thrive in this new era, delivering packaging solutions that meet the demands of both today’s customers and tomorrow’s planet.

FAQ:

1. What is the main benefit of paper-based takeout packaging over plastic?

Paper-based packaging is renewable, often compostable or recyclable, and less likely to leach chemicals, making it more environmentally friendly and compliant with global regulations.

2. Is kraft paper packaging suitable for greasy foods?

Yes, with the right coatings or multi-layer construction, kraft paper packaging resists grease and moisture, protecting both the food and the customer experience.

3. How do I choose the best packaging material for my restaurant?

Consider your menu, delivery model, local regulations, and customer expectations. Consulting with packaging experts like Bioleader® ensures the right match for your brand.

4. What materials are Papa John’s pizza boxes and bowls made from?

Papa John’s pizza boxes are made from food-grade corrugated cardboard, designed for heat retention and strength. The bowls are typically made from recyclable paperboard with a leak-resistant lining for hot dishes.

5. Are Papa John’s pizza boxes and bowls recyclable or compostable?

Most Papa John’s pizza boxes are recyclable if free from excessive food residue. The bowls may be recyclable or compostable depending on local facilities and specific materials used. Always check local guidelines.

6. Can you reheat food in a Papa John’s bowl or pizza box in the microwave?

Papa John’s bowls are generally microwave-safe for reheating. However, pizza boxes should not be microwaved as the cardboard can catch fire or become damaged. Always follow packaging instructions.

7. Do Papa John’s pizza boxes contain PFAS or harmful chemicals?

Papa John’s states that their boxes are made from food-safe materials and comply with regulatory standards. However, it’s advisable to consult the latest packaging information or request details from customer service for specific chemical content.

8. How do Papa John’s bowls and pizza boxes help keep food hot and fresh?

Papa John’s uses insulated, vented designs in both their pizza boxes and bowls to maintain heat, minimize sogginess, and preserve flavor during delivery or takeout, ensuring a quality dining experience.