Introduction: The Urgency of Sustainable Packaging

In the face of the global plastic crisis, the need for sustainable alternatives in packaging has never been more urgent. The environmental toll of single-use plastics is far-reaching, from the massive pollution of oceans to the contamination of ecosystems with microplastics. As businesses and consumers alike strive to reduce their environmental footprint, innovations like water-based coatings have emerged as a critical solution for plastic-free packaging in the foodservice industry.

This blog will explore the production process of water-based coating paper cups and bowls, highlighting their eco-friendly advantages over traditional plastic coatings. From the technical details of their application to the challenges and opportunities in scaling production, we will show how these water-based coatings are transforming food packaging into a more sustainable, safe, and compliant solution.

1. What Are Water-Based Coatings?

Definition: Understanding Water-Based Coatings

Water-based coatings are a type of protective layer used primarily in the packaging industry, especially for paper products such as cups, bowls, and trays. As the name suggests, the primary solvent used in these coatings is water, as opposed to petroleum-based solvents typically found in traditional coatings like polyethylene (PE). Water-based coatings are composed of water-soluble resins, natural additives, and other eco-friendly ingredients that combine to create a thin, durable protective layer on the surface of paper products.

These coatings are designed to provide various benefits, such as moisture resistance, oil resistance, and a smooth surface that is suitable for printing and branding. Importantly, they achieve all of these protective qualities without the harmful environmental impact of plastic coatings. Unlike traditional coatings that often contain volatile organic compounds (VOCs) and toxic chemicals like PFAS (per- and polyfluoroalkyl substances), water-based coatings are free from these hazardous materials, making them much safer for both consumers and the environment.

Composition of Water-Based Coatings

The composition of water-based coatings can vary depending on the manufacturer, but they generally consist of the following primary components:

Water-Based Resins: The main ingredient in water-based coatings is water-based resins. These resins, often derived from renewable resources like plant-based oils or synthetic polymers, are the key component responsible for the coating’s adhesion and moisture resistance. Unlike petroleum-based resins used in plastic coatings, water-based resins are biodegradable and more eco-friendly.

Natural Additives: Water-based coatings also contain various natural additives that help improve the performance and durability of the coating. These may include thickeners, stabilizers, and dispersants, which ensure that the coating adheres evenly to the surface of the paper product and remains stable throughout the drying process.

Surfactants and Coalescing Agents: Surfactants are added to improve the coating’s ability to spread evenly across the paper surface, while coalescing agents help the coating form a continuous film during the drying process. These agents play a crucial role in ensuring the coating is smooth and uniform, preventing defects like streaking or uneven coverage.

Water: Water acts as the solvent in the coating, helping to dissolve and carry the resins and additives. Once the coating is applied to the paper surface, the water evaporates, leaving behind a strong, durable layer.

How Water-Based Coatings Work

Water-based coatings work by forming a thin, protective barrier on paper surfaces. When applied to a paper product, the coating adheres to the surface due to the resin’s natural adhesive properties. Once applied, the water evaporates, and the resin binds to the paper, creating a solid and resistant layer. This layer protects the paper from moisture, oils, and grease, which is essential for food packaging products like cups and bowls that come into direct contact with liquids and food.

The coating also gives the paper products a smoother surface, which is particularly useful for printing and labeling. Water-based coatings allow high-quality graphics and logos to be printed onto the surface without the interference of plastic, ensuring that brands can still create visually appealing and functional packaging.

Key Features of Water-Based Coatings

Biodegradability: Water-based coatings are biodegradable, meaning they break down naturally over time without leaving toxic residues in the environment. This contrasts sharply with plastic coatings, which can take centuries to decompose and often end up polluting landfills or oceans.

Non-Toxic: Water-based coatings are free from harmful chemicals like PFAS and BPA (Bisphenol A), which are commonly found in traditional plastic coatings. These toxic chemicals are known to leach into food or beverages, posing health risks to consumers. Water-based coatings, however, do not contain these substances, making them much safer for food packaging.

Compostable: Many water-based coatings are compostable, meaning they can break down naturally in composting systems without harming the environment. This makes them a great choice for companies looking to produce packaging that can be disposed of sustainably.

Moisture and Oil Resistance: Despite being free from plastic, water-based coatings are still capable of offering high levels of moisture and oil resistance, which is essential for food packaging. This makes water-based coated paper products ideal for holding hot, greasy, or liquid food items without compromising their structural integrity.

Applications of Water-Based Coatings

Water-based coatings are used in a variety of industries, particularly in foodservice packaging, where the demand for sustainable, non-toxic, and recyclable solutions is rising. Some common applications of water-based coatings include:

|  |

Paper Cups and Bowls: Water-based coatings are commonly used to coat paper cups and bowls, providing a moisture and oil-resistant barrier that is safe for food contact. These coatings ensure that paper cups can hold hot liquids without leaking or becoming soggy.

Trays and Takeout Containers: Many takeout containers and trays are coated with water-based coatings to provide the necessary protection against grease, moisture, and food particles. These containers can be composted or recycled, making them an ideal choice for businesses looking to reduce waste.

Food Packaging: Water-based coatings are also used in a wide range of other food packaging products, such as food cartons and wraps, to prevent moisture from seeping in and spoiling the product inside. They provide an eco-friendly alternative to plastic wraps and films.

2. The Production Process of Water-Based Coated Paper Cups and Bowls

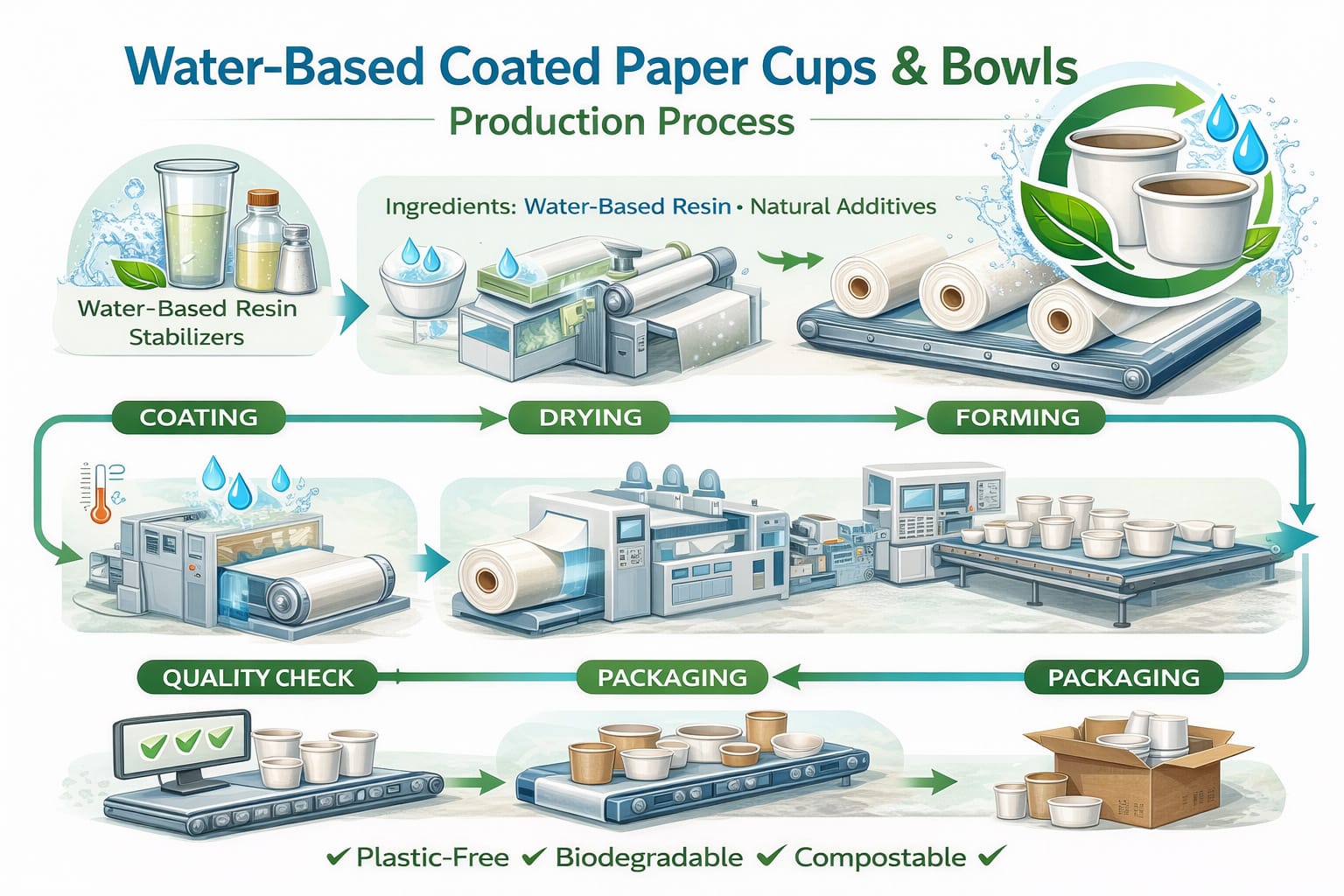

The production of water-based coated paper cups and bowls involves several stages, each crucial to ensuring the product’s durability, safety, and eco-friendliness. Let’s take a closer look at the key steps involved in the production process of these sustainable foodservice products.

Step 1: Paper Selection and Preparation

The production process starts with selecting the right type of paper for the cups and bowls. This paper is typically made from renewable resources such as wood pulp or recycled paper. Once the raw paper is sourced, it is prepared by passing through various processes, including pulping, refining, and drying, to achieve the desired thickness and strength.

Step 2: Coating Application

The next stage involves applying the water-based coating to the paper. This is typically done through a process called direct gravure coating or flexo printing, where a thin layer of the water-based resin is evenly spread onto the surface of the paper. In the gravure process, the coating material is transferred from a roller onto the paper, whereas in flexo printing, the coating is applied using a flexible printing plate.

The key to ensuring a uniform and durable layer of coating is the careful management of the application process. The paper must be evenly coated to prevent defects such as streaking or uneven coverage. This is where the choice of resins, additives, and surfactants becomes critical to achieving a smooth, consistent layer.

Step 3: Drying Process

Once the coating is applied, the next step is drying. The coated paper is passed through a drying oven or conveyor belt, where hot air is used to evaporate the water content in the coating. This leaves behind a strong, adhesive resin that bonds firmly to the paper surface, creating a protective barrier.

The drying process is crucial for the proper setting of the coating and to ensure that the paper maintains its strength and resistance to moisture, oil, and grease. If the drying process is not controlled properly, it can result in defects such as blistering or cracking of the coating.

Step 4: Shaping and Molding

Once the water-based coating has dried and adhered to the paper, the next step is shaping the paper into cups or bowls. For paper cups, the coated paper is typically cut into a flat shape and then rolled and sealed into the familiar cylindrical form. For paper bowls, the coated paper is molded into the desired bowl shape, often using heat and pressure.

During this stage, precise control is required to ensure that the paper retains its protective coating while also maintaining the required structural integrity for use in foodservice applications.

Step 5: Quality Control and Inspection

After shaping, each cup or bowl undergoes a thorough quality control inspection. This involves checking the coating for uniformity, ensuring that there are no defects, and verifying that the paper maintains the required strength and durability. Inspections are also conducted to ensure that the cups and bowls meet all relevant food safety and environmental standards.

Step 6: Packaging and Distribution

Once the paper cups and bowls pass quality checks, they are ready for packaging. Typically, these products are packed in bulk and prepared for distribution. Since water-based coatings are biodegradable, the packaging materials used for the finished products are also often eco-friendly, further supporting the sustainability of the product.

3. Benefits and Advantages of Water-Based Coatings

Water-based coatings offer numerous benefits over traditional plastic coatings, making them an ideal choice for businesses seeking to embrace more sustainable practices. Here are some of the key advantages:

Eco-Friendly and Biodegradable:

Unlike plastic coatings, which can take hundreds of years to break down in landfills, water-based coating cups are biodegradable and compostable. This makes them a much more environmentally responsible option, reducing waste and pollution.

Non-Toxic and Safe for Food Contact:

Water-based coatings are free from harmful chemicals like PFAS, BPA, and VOCs, which are commonly found in traditional coatings. This makes them a safer choice for food packaging, as there are no harmful substances leaching into the food or beverages.

Moisture and Oil Resistance:

Despite being free from plastic, water-based coatings still provide excellent moisture and oil resistance, which is crucial for food packaging. This ensures that paper cups and bowls can hold liquids and greasy foods without compromising their structural integrity.

Cost-Effective Production:

While the initial cost of producing water-based coated paper products may be slightly higher than traditional coatings, the long-term benefits, including improved consumer safety, compliance with environmental regulations, and potential cost savings through reduced waste management, make it a worthwhile investment.

4. Challenges and Solutions in the Production Process

As with any production process, there are challenges to overcome when using water-based coatings. Some of the main challenges include:

Coating Consistency:

Achieving uniform coating distribution across the surface of the paper can be difficult, especially when working with materials that vary in texture or thickness. This can lead to defects like streaks, gaps, or uneven coverage.

Drying Efficiency:

The drying process is crucial in ensuring that the coating bonds well with the paper. However, excessive drying times or improperly controlled temperature settings can result in coating failure, leading to issues like cracking, peeling, or reduced moisture resistance.

Solution:

To address these challenges, manufacturers can invest in high-quality coating equipment, such as precision gravure or flexo printers, and ensure that the drying processes are optimized for different paper types. Additionally, training staff on best practices for coating application and drying can help improve the overall production quality.

5. Water-Based Coatings: Meeting Environmental Regulations and Consumer Demands

Water-based coatings not only provide a safer and more sustainable packaging solution, but they also help brands comply with increasingly stringent environmental regulations. With many countries now enacting laws to reduce plastic waste and promote compostable packaging, water-based coatings are an ideal solution for businesses looking to align with global sustainability trends.

In addition to regulatory compliance, consumer demand for eco-friendly products continues to rise. Consumers are becoming more aware of the environmental impact of packaging materials, and many are choosing brands that prioritize sustainability. By switching to certified water-based coated paper cups and bowls, companies can demonstrate their commitment to the environment and cater to this growing market demand.

Conclusion: A Step Toward Sustainable Packaging

The use of water-based coatings is revolutionizing the foodservice packaging industry, offering a viable alternative to plastic coatings that are both safer for consumers and better for the planet. By understanding the production process and the benefits of water-based coatings, manufacturers can improve their production processes, reduce costs, and stay ahead of the curve in meeting regulatory requirements and consumer expectations.

As the world continues to prioritize sustainability, water-based coatings represent an important step toward creating packaging solutions that align with eco-friendly goals while still meeting the practical needs of the foodservice industry.

Water-Based Coatings: Sustainable and Safe for Packaging

Quick Summary: Water-based coatings offer a biodegradable, non-toxic alternative to traditional plastic coatings in food packaging. They provide moisture and oil resistance while being free of harmful chemicals like PFAS and BPA.

- What Are Water-Based Coatings?

Water-based coatings are eco-friendly protective layers applied to paper products. They use water as the solvent, unlike plastic coatings that use harmful chemicals. These coatings are biodegradable and compostable, making them a safe and sustainable choice.

- Why Choose Water-Based Coatings?

They are free from toxic chemicals, offering a safer food packaging option. They are moisture and oil-resistant, making them ideal for holding liquids and greasy foods without compromising structural integrity.

- Key Benefits

-Eco-Friendly: Biodegradable and compostable. – Non-Toxic: Free from PFAS, BPA, and VOCs. – Durable: Provides excellent moisture and oil resistance.

- Why Is This Important for Your Business?

With increasing consumer demand for sustainability and stricter environmental regulations, water-based coatings provide a compliant, safe, and cost-effective solution for eco-conscious brands.