Introduction

The explosive growth of takeout, takeaway, and to-go food has reshaped the global foodservice industry. With the rise of food delivery platforms and shifting consumer lifestyles, packaging is no longer an afterthought—it’s a strategic touchpoint for both brands and end users. Today’s consumers are more discerning than ever. They want food packaging that guarantees safety, delivers a premium experience, aligns with environmental values, and supports their daily routines without compromise.

But how can brands keep up with these rising expectations—especially as single-use plastics face public backlash and regulatory bans? The answer lies in a new generation of compostable, eco-friendly containers that address both functional and emotional needs.

This article breaks down the nine most pressing consumer demands for takeout packaging in 2025, with a focus on how compostable packaging—led by innovators like Bioleader®—offers a total solution.

1. Food Safety & Hygiene

The Non-Negotiable Foundation

Food safety is the baseline expectation for any takeout experience. Modern consumers are acutely aware of foodborne illnesses, chemical migration, and the risks associated with substandard materials. Packaging must be certified food-grade, free from harmful substances (BPA, PFAS, phthalates), and manufactured in hygienic conditions.

Compostable containers, especially those made from bagasse, CPLA, or cornstarch, are typically certified to the highest international food safety standards. They are non-toxic, odorless, and resistant to oil, grease, and moisture, ensuring the food arrives just as fresh and safe as it left the kitchen. For brands, using certified compostable packaging is more than compliance—it’s a trust signal that can win repeat customers.

2. Leak-Proof & Sturdy Design

The Ultimate Test: Delivery in Motion

No consumer wants to open a bag and find spilled soup, soggy salads, or leaking sauces. With longer delivery distances and multi-order stacking, packaging must stand up to real-world transport challenges. Durability is especially crucial for dishes with broths, gravies, or high oil content.

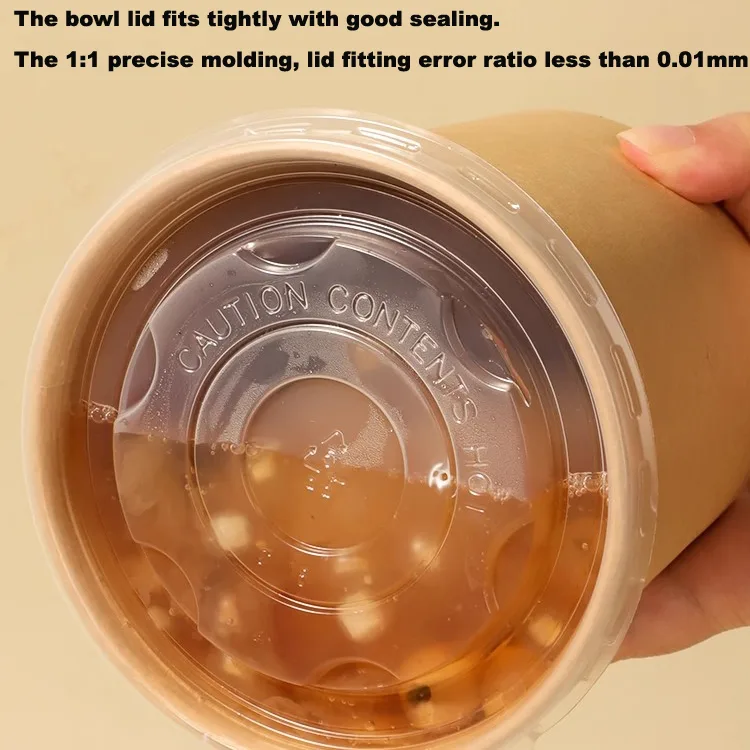

Advanced molded pulp technology and smart design—such as interlocking lids, reinforced edges, and anti-leak coatings—are now standard in high-quality compostable containers. These features ensure that even the messiest meals arrive intact. Leading brands have engineered their products for structural strength, so takeaway meals withstand bumps, stacking, and rough handling without fail.

|  |

3. Temperature & Freshness Retention

Preserving Flavor, Texture, and Enjoyment

Consumers expect hot food to stay hot, and cold food to remain chilled—without sogginess, condensation, or off-flavors. The reality: Poor insulation and moisture control can ruin the experience before the first bite.

Whether it’s ramen, fried chicken, sushi, or fresh salad, retaining the intended temperature and freshness is a key driver of satisfaction and loyalty.

Compostable containers are evolving rapidly in this area. Dual-layer bagasse trays, insulated CPLA lids, and innovative venting systems help lock in heat or cold and minimize steam buildup. Some manufacturers have pioneered micro-vent technology to release excess moisture without letting heat escape, maintaining crispness and preventing wilting. This level of thermal performance was once exclusive to plastic—now it’s the standard for premium eco-friendly packaging.

4. Temperature Compatibility (Microwave & Freezer Safe)

Versatility for Modern Lifestyles

Today’s consumers want flexibility. Many expect to refrigerate, reheat, or even freeze leftovers directly in the takeout container. But not all packaging materials are up to the task—some deform, leach chemicals, or become brittle under stress.

Quality compostable packaging stands out for its range:

Microwave-safe: Bagasse, CPLA, and PLA-based containers are designed to withstand high temperatures, enabling safe reheating without warping or toxic fumes.

Freezer-safe: These materials hold up under low temperatures, resisting cracking or moisture absorption, which is ideal for meal prep, batch orders, or food storage.

This adaptability supports both convenience and sustainability—consumers use fewer resources and brands can tout a “one-container-for-all-purposes” message.

5. Portability & Stackability

Designed for Delivery—and Daily Life

Takeout isn’t just about eating at home; it’s about grabbing lunch at the office, picnicking in the park, or sharing meals on the go. Packaging must be easy to carry, hold, and transport—without risk of tipping, crushing, or accidental opening.

Stackability is another overlooked detail: Delivery drivers, kitchen staff, and consumers all benefit from containers that nest securely, optimizing space and minimizing spills.

Compostable packaging makers have responded with ergonomic designs—flat lids, ribbed sides for grip, and standardized footprints for effortless stacking. Lightweight but strong, these containers enable high-efficiency delivery and positive unboxing experiences. For QSR chains and cloud kitchens, this translates directly into operational efficiency and lower delivery errors.

|  |

6. Branding & Customization

Beyond the Logo: Telling a Sustainable Story

Packaging is the first physical touchpoint with customers in the delivery journey. It’s a key branding tool—conveying quality, trust, and environmental commitment.

Consumers increasingly expect packaging that looks and feels premium, but also clearly communicates a brand’s eco-friendly values.

Modern compostable packaging is highly customizable:

Embossed or printed logos demonstrate brand professionalism.

Color, texture, and form can be tailored to enhance the dining experience.

Eco-labels and sustainability certifications (e.g., “100% compostable,” “plant-based,” “BPI certified”) serve as badges of trust.

|  |

Bioleader® and other industry leaders offer end-to-end customization, enabling restaurants and food brands to stand out and build lasting impressions—all while aligning with green values.

7. Eco-Friendliness & Compostability

Meeting Environmental Expectations—And Regulatory Demands

Perhaps the biggest shift in consumer attitudes: Packaging is now a moral and environmental issue.

A majority of food delivery customers—especially younger generations—demand alternatives to single-use plastic. They want assurances that their packaging won’t end up in a landfill or pollute waterways.

Increasingly, cities and countries are enacting bans or taxes on plastics, making sustainable packaging a legal necessity.

Compostable containers are at the heart of this movement.

Made from renewable plant fibers like sugarcane bagasse, corn starch, or PLA, these containers decompose rapidly in industrial or home composting environments, returning nutrients to the earth. Many brands invest in third-party certifications to validate claims, providing peace of mind to consumers and compliance for businesses.

Adopting compostable packaging not only satisfies customer demands—it signals true ESG leadership and prepares brands for tomorrow’s regulatory landscape.

8. Affordable Cost & Value

Striking the Balance: Green Without the Premium

A key pain point: Many consumers and businesses are concerned that sustainable options come with a high price tag. While early-generation eco-packaging did carry a premium, this is rapidly changing.

Compostable packaging is becoming more cost-competitive as technology scales and supply chains mature. For restaurants, total value isn’t just the unit price: Reducing customer complaints, improving brand loyalty, and future-proofing against regulatory penalties can all justify a modest cost difference.

Moreover, savvy consumers are willing to pay a small premium for packaging that aligns with their values—especially when the added benefits (such as safety, design, and convenience) are clear and tangible.

Industry leaders like Bioleader® are investing in automated production, material innovation, and global logistics to deliver both affordability and quality, making sustainable packaging accessible to brands of all sizes.

9. Convenience & Usability

Seamless Experience—From Kitchen to Table

For packaging to truly satisfy, it must be intuitive to use. Consumers want containers that are easy to open, close, and reseal. They appreciate thoughtful features: anti-scald grips, tamper-evident seals, portioned compartments, and utensils that are sturdy yet compostable.

Top-tier compostable products are designed for real user needs:

Snap-fit lids to prevent spills

Easy-peel tabs for hassle-free access

Stackable cutlery and integrated compartments for meal variety

Clear labeling for recycling or composting instructions

This focus on usability reduces frustration, speeds up meal enjoyment, and supports sustainable disposal—all key to a five-star takeout experience.

How Compostable Packaging Empowers Food Brands

Industry Best Practices & Real-World Results

Leading food brands and delivery platforms are reaping the benefits of next-generation compostable packaging. For example:

Brand Differentiation: Companies that switch to certified compostable containers are gaining a competitive edge, attracting environmentally conscious customers, and boosting positive reviews.

Operational Efficiency: Standardized, stackable packaging reduces delivery errors and food waste, driving down costs and improving customer retention.

Regulatory Readiness: Brands using compostable materials are positioned to thrive amid tightening global regulations, minimizing compliance risks and protecting reputational value.

Bioleader®’s clients, including fast-casual chains and cloud kitchens, have reported higher customer satisfaction, fewer complaints about leaks or sogginess, and increased brand loyalty after upgrading to compostable solutions. The message is clear: Packaging innovation is no longer optional—it’s a business imperative.

Conclusion & Strategic Outlook

The future of takeout and food delivery belongs to brands that put the consumer first—offering safe, convenient, and sustainable packaging solutions without compromise.

The nine key consumer demands outlined above are not fleeting trends but structural shifts in the way people interact with food and packaging. Compostable containers, driven by material science and thoughtful design, are uniquely positioned to deliver on these expectations at scale.

The path forward for food businesses and packaging decision-makers is clear: Invest in compostable, branded, user-centric packaging. Not only does this meet consumer and regulatory demands, but it also strengthens brand trust and supports long-term growth in an increasingly competitive market.

Bioleader® remains committed to empowering the food industry with world-class compostable packaging solutions. The right container doesn’t just carry food; it carries your brand into the future.

FAQ (People Also Ask)

1. What are the best materials for eco-friendly takeout food packaging?

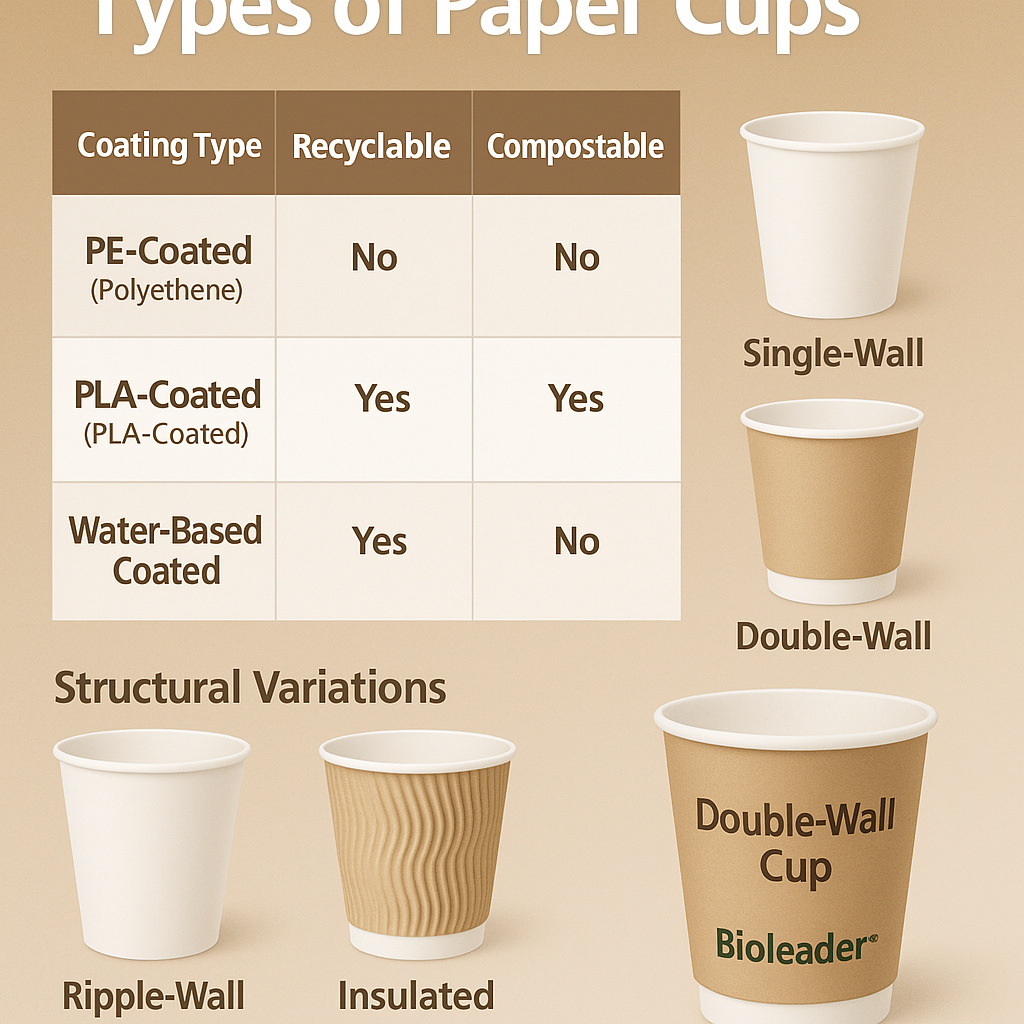

The leading materials include sugarcane bagasse, kraft paper, and PLA (polylactic acid). These materials are fully compostable, food-safe, and perform well for both hot and cold foods.

2. Are compostable food containers really leak-proof?

Yes, high-quality compostable containers use advanced molded pulp designs and food-safe coatings, making them leak-proof for soups, sauces, and oily dishes. They’re tested for both delivery and in-store use.

3. Can I microwave or freeze biodegradable takeout containers?

Most modern compostable food boxes are microwave-safe and freezer-safe. They withstand temperature changes without deforming or releasing harmful chemicals, making reheating and storage safe and convenient.

4. How long do compostable containers take to decompose?

Under industrial composting, bagasse and PLA containers typically decompose within 60–120 days. Home composting may take longer but still offers a significant environmental benefit over plastic.

5. Do eco-friendly takeout boxes affect food taste or freshness?

No. Certified compostable containers are odorless and designed to preserve food taste, moisture, and temperature, delivering a satisfying dining experience without flavor transfer.

6. Can I print my restaurant’s logo on compostable packaging?

Absolutely. Most compostable packaging supports full customization, including logo printing, brand colors, and eco-messaging—helping restaurants reinforce their brand identity and sustainability commitment.

7. Are compostable food boxes more expensive than plastic?

While costs have traditionally been higher, increased demand and advances in manufacturing have significantly narrowed the price gap. Many restaurants find the brand and regulatory benefits outweigh any small price difference.

8. What certifications should I look for in sustainable takeout packaging?

Key certifications include BPI, OK Compost, and FDA food-contact compliance. These labels ensure the packaging is genuinely compostable, food-safe, and meets international sustainability standards.