Yes, most compostable cutlery can safely handle both hot and cold foods. CPLA cutlery, in particular, is engineered for higher heat resistance, making it suitable for soups and hot meals.

Under industrial composting conditions, bio plastic cutlery generally decomposes within 90 to 180 days, depending on the material and composting environment — pulp molding technology.

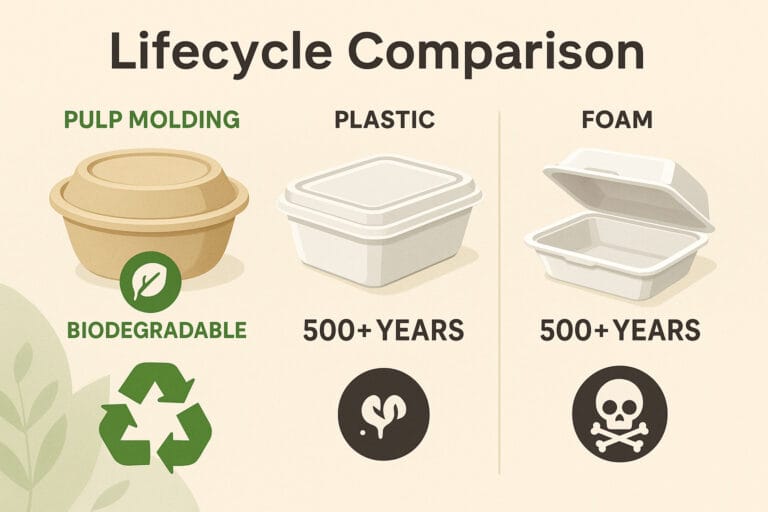

Compostable sporks reduce reliance on petroleum-based plastics, break down naturally without leaving microplastics, and support a circular economy by turning waste into compost — pulp molding technology.

Higher pricing reflects system-level manufacturing capability rather than raw material cost alone. Precision molds, multi-fiber engineering, tighter CTQ control, and lower defect rates all increase production cost but deliver consistent quality, better appearance, and predictable performance at scale—reducing total packaging risk for buyers.

Molded pulp trays are typically customized through dedicated tooling to match product geometry, load requirements, and presentation needs. Customization may include tray structure, cavity layout, surface finish level, and compatibility with automated packing lines, depending on project volume and specifications — pulp molding technology.

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

Get the Catalogue Products List & Contact Us Now! 👉

📧 Email : [email protected]

📲 WhatsApp : +86-15980856610

🟢 Wechat : bioleader

📍 Add : No.39 Xinglong Road, Xiamen, China

Copyright © 2015–2025 Xiamen Bioleader Environmental Protection Co., Ltd | All Rights Reserved. Privacy Policy | AI Policy | Sitemap

WhatsApp us