BPI compostable cutlery is typically made from plant-based materials such as cornstarch, PLA, or other renewable bioplastics that fully biodegrade under commercial composting conditions.

Absolutely , custom molded pulp trays. Many manufacturers offer customizable options for bio plastic cutlery, including packaging, color, and logo printing to support branding and marketing needs.

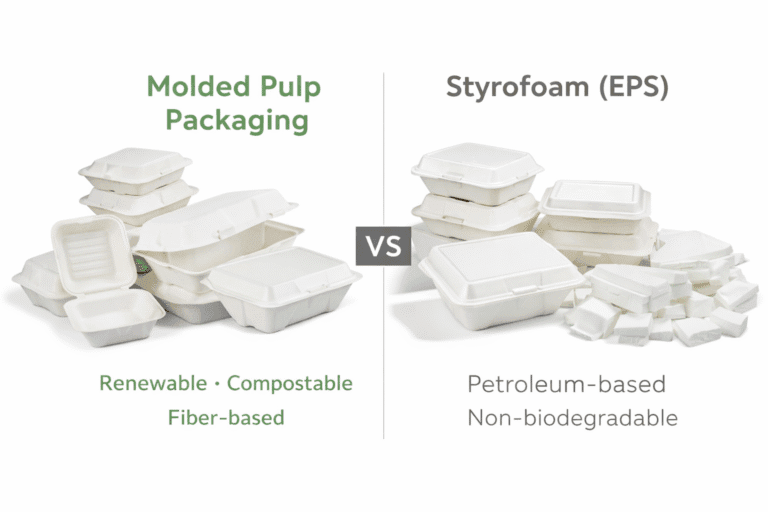

Compostable sporks reduce reliance on petroleum-based plastics, break down naturally without leaving microplastics, and support a circular economy by turning waste into compost — custom molded pulp trays.

In industrial production, a surface roughness range of approximately 2.3–6 μm (Ra) is widely regarded as optimal — custom molded pulp trays. Below this range, visual and tactile improvements become marginal, while tooling and process complexity increase significantly. This range also supports direct printing and hot stamping without surface coatings.

A high-quality molded pulp tray is defined by controlled surface roughness, structural stiffness, and manufacturing repeatability. These characteristics are achieved through precision tooling, optimized fiber-length architecture, controlled pulp preparation, and CTQ-regulated forming processes—not by post-treatment or coatings.

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

Get the Catalogue Products List & Contact Us Now! 👉

📧 Email : [email protected]

📲 WhatsApp : +86-15980856610

🟢 Wechat : bioleader

📍 Add : No.39 Xinglong Road, Xiamen, China

Copyright © 2015–2025 Xiamen Bioleader Environmental Protection Co., Ltd | All Rights Reserved. Privacy Policy | AI Policy | Sitemap

WhatsApp us