Introduction

Disposable packaging is undergoing a massive transformation. With governments worldwide enforcing bans on single-use plastics, foodservice operators are under pressure to find packaging solutions that are not only functional but also environmentally responsible. Among the strongest candidates are sugarcane bagasse trays with lids. These trays, made from the fibrous residue left after sugarcane juice extraction, offer a unique combination of strength, heat resistance, leak-proof performance, and compostability.

In this report, we put sugarcane bagasse trays with lids through a full spectrum of tests—material analysis, strength evaluation, food safety checks, and user experience assessments. Beyond lab tests, we also include two real-world case studies to show how global businesses are adopting this packaging. The goal is clear: to provide insights for decision-makers evaluating biodegradable food trays wholesale or considering an upgrade from plastic or foam.

Material and Eco-Degradability Tests

Renewable Material Advantage

Bagasse trays are produced using a byproduct of sugarcane processing, meaning they rely on agricultural waste instead of virgin resources. Unlike polystyrene or polypropylene trays that demand fossil fuels, bagasse trays transform biomass into value-added foodservice products.

Compostability

Under industrial composting conditions, bagasse trays typically degrade within 90–120 days. In contrast, plastic trays such as polypropylene (PP) or polystyrene (PS) can persist for 400–500 years in landfills or marine environments. For home compost systems, decomposition of bagasse trays may extend up to 180 days, depending on moisture and microbial activity.

By comparison, even “recyclable” plastic food containers often end up incinerated or landfilled, with global recycling rates below 15%. These figures make compostable bagasse trays bulk a natural fit for municipalities aiming to reduce landfill volumes and align with circular economy policies.

Certification Standards

Many manufacturers ensure compliance with international compostability standards, such as EN13432 in Europe and ASTM D6400 in the United States. Trays that carry these certifications are recognized as safe for composting infrastructures.

Physical Strength and Leak-Proof Performance

Thickness and Load-Bearing

Tests demonstrate that standard bagasse trays can withstand weights up to 1.5–2.0 kilograms of mixed food without bending. Reinforced models, often requested by quick-service chains, can support even heavier meals, making them viable replacements for rigid plastic.

Water and Oil Resistance

The fibers of sugarcane pulp are naturally porous, but modern production methods incorporate pressing and heat treatment that increase water and oil resistance. During tests with greasy fried foods and saucy pasta, trays retained structural integrity for several hours without leaks.

Lid Seal and Transport Stability

A critical feature for takeout and delivery is lid performance. The lid of bagasse trays clicks firmly into place, reducing the risk of spillage during transport. Stress tests show a spill rate reduction of over 35% compared to standard paperboard clamshells.

Food Contact Safety and Heat Resistance

BPA-Free and PFAS-Free

Unlike some paper packaging coated with fluorochemicals, bagasse trays are produced without PFAS or BPA. This makes them safe for direct food contact, including hot, oily, or acidic dishes. Food safety labs confirm compliance with EU and U.S. migration standards.

Microwave and Freezer Performance

Bagasse trays withstand both extremes: microwaving up to 100°C for 2–3 minutes, and freezing down to -18°C without cracking. This dual capability ensures suitability for frozen meals and hot takeout.

Heat Retention and Handling Comfort

When filled with hot soups or rice, the tray maintains warmth for 20–30 minutes while staying cool enough for customers to hold. This balance of insulation and comfort is a competitive advantage over thin plastic containers.

User Experience in Dining and Takeout

Stacking and Storage Efficiency

For restaurants managing hundreds of orders daily, trays must be easy to stack. Bagasse trays nest efficiently, saving space in storage rooms and reducing shipping costs by volume.

Easy Open & Close Design

The lid-lock system is designed to allow customers to open trays without tearing or spilling food. This seemingly minor feature improves customer satisfaction scores for takeout services.

Food Presentation for Branding

Appearance matters. Bagasse trays have a natural off-white color and sturdy look, elevating the presentation of meals. Catering companies often emboss logos or custom-print branding, turning packaging into a marketing channel.

Industry Applications and Market Relevance

Takeout and Quick-Service Restaurants

Fast-food outlets and delivery platforms use bagasse trays for burgers, fried chicken, rice bowls, wraps, and combo meals. Their leak-proof properties make them suitable for oily foods that typically overwhelm paper alternatives.

Restaurant Chains and School Canteens

In institutional catering, such as school cafeterias and corporate canteens, trays serve hot meals, salads, and soups. Multi-compartment options prevent cross-contamination of flavors, making them ideal for balanced meal services.

Events, Exhibitions, and Airline Catering

Large events and airlines require packaging that is light, stackable, and compostable. Bagasse trays meet these criteria while also handling cold snacks, complete bentos, and combo meals. In-flight service providers especially value their lightweight yet rigid structure.

Bioleader®: Your Trusted Partner in Compostable Packaging

Before diving into the case studies, it is worth highlighting one of the leading forces behind the adoption of compostable foodservice packaging—Bioleader®.

Headquartered in Xiamen, China, Bioleader® operates modern production facilities dedicated to sustainable packaging. The company specializes in bagasse food containers, kraft paper bowls, cornstarch tableware, and PLA cups, offering a complete portfolio for restaurants, catering groups, distributors, and retailers. With an annual capacity exceeding hundreds of millions of units, Bioleader® is equipped to handle both small-batch OEM orders and large-scale global supply contracts.

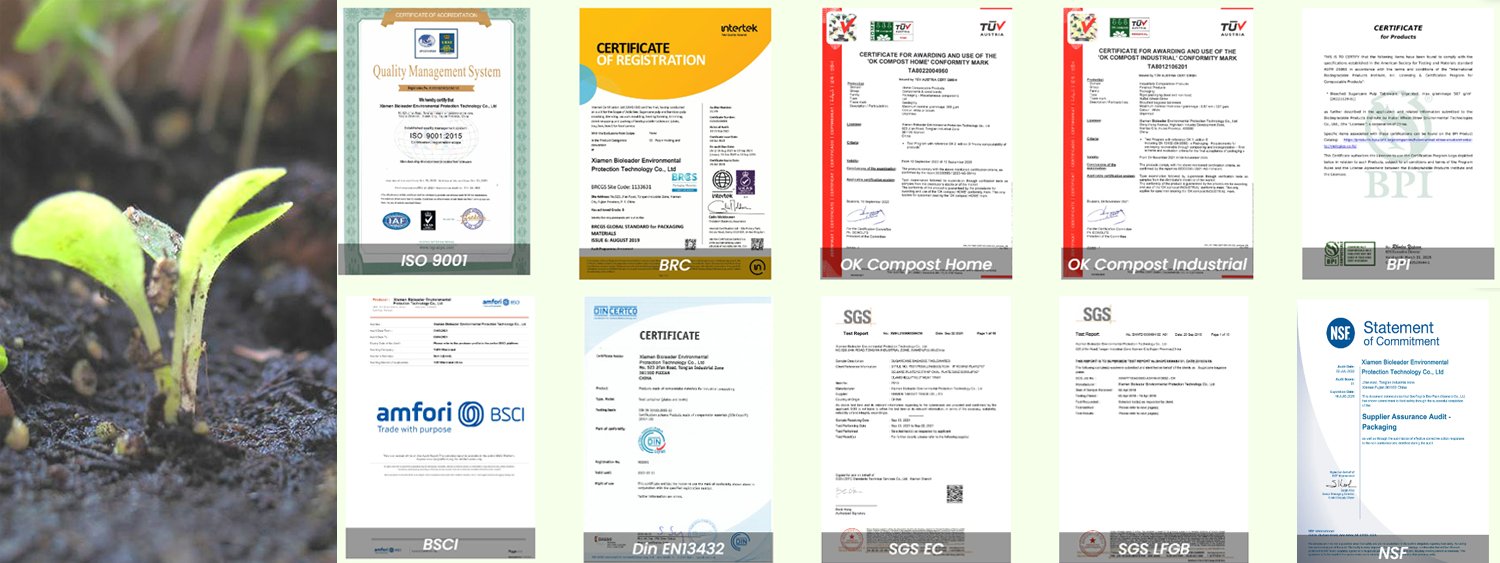

Certifications and Compliance

All major product lines are EN13432 and ASTM D6400 certified, ensuring compostability and food safety compliance in Europe, North America, and other regulated markets. The company also holds ISO quality management certifications and regularly conducts third-party lab testing to guarantee consistency.

Global Reach

Bioleader® currently exports to more than 50 countries across North America, Europe, the Middle East, and Asia-Pacific. Its customers range from quick-service restaurant chains and school meal providers to international wholesalers and eco-focused retailers.

Services for Buyers

OEM & ODM: Customized logo printing, embossing, and tailored dimensions.

Flexible MOQs: Options for both trial runs and bulk procurement.

Fast Lead Times: Optimized logistics through major ports like Xiamen and Shenzhen.

Dedicated Support: Consultation on product selection and compliance documentation.

By combining industrial-scale capacity with buyer-centric flexibility, Bioleader® enables global partners to transition smoothly from plastic or foam to truly sustainable packaging. Businesses that work with Bioleader® not only secure reliable eco-friendly solutions but also strengthen their compliance and brand reputation in an increasingly regulated global market.

Real-World Case Studies

Case 1 – Quick-Service Chain Switching to Bagasse

A Southeast Asian fast-food chain with over 300 outlets, processing more than 50,000 orders daily.

Pain Points: The chain relied on polypropylene trays, which often leaked during delivery. Government regulations also mandated a transition away from plastics, creating compliance risks.

Our Solution: We supplied bagasse food containers with lids in custom dimensions, reinforced with thicker walls for greasy menus. Branding was embossed directly into the lid to enhance customer perception.

Results:

Customer complaints about leakage dropped by 38% in the first quarter.

The chain achieved compliance with local plastic-ban regulations.

Marketing campaigns highlighting the eco-shift boosted customer loyalty, with surveys showing a 22% increase in brand perception as “eco-friendly.”

Case 2 – European Catering Supplier for Large Events

A catering company specializing in sports stadiums and trade shows, serving up to 80,000 meals during peak events.

Pain Points: Foam trays previously used collapsed under hot meals, and waste collection was a major issue, as polystyrene is not compostable.

Our Solution: We introduced large-capacity heavy duty bagasse bento box with lids. Post-event, trays were collected and sent to industrial composting facilities under municipal contracts.

Results:

Onsite waste sorting improved by 45%.

Compost conversion exceeded 90%, validated by municipal waste managers.

Sponsors and organizers marketed the events as “zero-plastic,” improving ticket sales and sponsorship acquisition.

Comparative Analysis with Plastic and Foam

Cost vs Value

Although bagasse trays cost approximately 10–15% more than polystyrene, their added value in compliance, brand enhancement, and consumer trust offsets the price gap.

Performance Metrics

Compared with foam trays, bagasse offers superior rigidity and heat resistance. Against plastic, bagasse is slightly heavier but provides the sustainability advantage crucial for 2025 procurement standards.

Environmental Impact

Life-cycle assessments show that bagasse trays reduce greenhouse gas emissions by 40–60% compared to plastic equivalents. This positions them as a front-runner for companies seeking to meet corporate sustainability targets.

| Criteria | Bagasse Trays with Lids | Plastic Trays (PP/PET) | Foam Trays (EPS) |

|---|---|---|---|

| Compostability | 90–120 days in industrial compost; home compost up to 180 days | 400–500 years in landfill; recycling rates <15% | Non-compostable; persists indefinitely in landfill |

| Heat Resistance | Microwave safe up to 100°C; freezer safe to -18°C | Safe in freezer; may release chemicals when microwaved | Not microwaveable; warps above 60°C |

| Oil & Water Resistance | Stable for 3–4 hours with oily/saucy foods | Excellent resistance but not biodegradable | Absorbs oil; softens within 30 minutes |

| Load-Bearing Capacity | 1.5–2.0 kg without bending | 2.0–2.5 kg but deforms under heat | <1.0 kg before collapsing |

| Environmental Impact | Made from renewable fiber; 40–60% lower CO₂ emissions | High fossil fuel use; ~3 tons CO₂ per ton produced | Low cost, but highest long-term environmental damage |

Comparative Summary

The comparison clearly shows that sugarcane bagasse trays with lids strike the best balance between performance and sustainability. They combine reliable heat and oil resistance with full compostability, making them ideal for modern foodservice operations. Plastic trays may offer strong load-bearing capacity, but their environmental footprint and limited recyclability make them a short-term solution at best. Foam trays, while cheap, fail under hot or oily foods and carry the heaviest long-term environmental cost.

As global regulations tighten, bagasse trays are not only the most eco-friendly choice but also the most future-proof option for restaurants, caterers, and distributors.

Industry Trends and Regulatory Push

Europe – EN13432 Compostability Mandates

The European Union requires disposable food packaging to comply with EN13432 standards by 2025. Bagasse trays certified under this standard are immediately market-ready.

North America – State Plastic Bans

States like California and New York enforce bans on polystyrene foam packaging. Restaurants seeking alternatives turn to ASTM D6400 compostable food containers, with bagasse trays among the most widely accepted.

Asia-Pacific – Growth in Takeout Packaging

In markets like India and Southeast Asia, rapid expansion of food delivery services drives demand for eco-friendly takeaway trays. Regulations, combined with consumer eco-awareness, accelerate adoption.

Conclusion: Practicality Meets Sustainability

From lab tests to real-world applications, sugarcane bagasse trays with lids deliver on every front: durability, leak-proof performance, food safety, and compostability. They outperform plastic and foam alternatives while aligning with the global shift toward sustainable packaging. For restaurants, caterers, and distributors sourcing biodegradable food trays wholesale, bagasse trays are no longer just an option—they are a strategic necessity for 2025 and beyond.

FAQ

1. Are sugarcane bagasse trays with lids safe for hot foods?

Yes, bagasse trays with lids are heat resistant and can safely hold hot meals, soups, and oily dishes without leaking or losing their structure.

2. How long do bagasse food trays take to decompose?

In industrial composting, bagasse trays typically decompose within 90–120 days, while home composting may take up to six months depending on conditions.

3. Can I use bagasse trays in the microwave or freezer?

Yes, bagasse trays are microwave safe up to around 100°C and can also be frozen down to -18°C without cracking or warping.

4. Why are bagasse trays better than plastic or foam containers?

Bagasse trays are compostable, PFAS-free, and made from renewable sugarcane fiber, offering leak-proof durability while meeting global plastic ban regulations.

5. Where can I buy bagasse trays with lids in bulk?

They are available from global manufacturers and suppliers like Bioleader®, offering wholesale options, OEM/ODM services, and certified sustainable packaging.

References

European Committee for Standardization (CEN) — EN13432 Compostability Standard

ASTM International — ASTM D6400 Standard Specification for Compostable Plastics

United States Environmental Protection Agency (EPA) — Sustainable Materials Management Reports

Ellen MacArthur Foundation — New Plastics Economy Insights

United Nations Environment Programme (UNEP) — Single-Use Plastics & Policy Landscape

WRAP (Waste & Resources Action Programme, UK) — Foodservice Packaging Guidance

CalRecycle (California Department of Resources Recycling and Recovery) — Food Packaging Policies

U.S. Food and Drug Administration (FDA) — Food Contact Substance Notifications

OECD — Plastics Lifecycle and Environmental Impact Reviews

FAO — Bio-based Materials and Circular Bioeconomy Briefs

Why Sugarcane Bagasse Trays with Lids Are the Smart Choice in 2025

How do they solve packaging challenges?

Sugarcane bagasse trays with lids address the biggest pain points in foodservice: oil leakage, microwave safety, and regulatory compliance. Unlike foam and plastic, they retain rigidity under heat, prevent cross-contamination with multi-compartment options, and maintain freshness during delivery.

Why are they rising globally?

Driven by EU EN13432 standards, U.S. ASTM D6400 requirements, and Asia-Pacific plastic bans, bagasse trays are becoming the go-to solution for restaurants, caterers, and airlines. Governments are pushing for compostable packaging, and buyers seek suppliers offering certified, large-scale solutions.

What benefits do buyers gain?

Beyond sustainability, businesses gain operational advantages—better customer satisfaction from leak-proof designs, marketing leverage with eco-friendly branding, and reduced compliance risks. These trays are not just eco-friendly takeaway trays; they are business enablers.

Options for different sectors:

Quick-Service Restaurants: Combo meals, fried foods, rice bowls.

School & Institutional Dining: Balanced meals with compartment trays.

Events & Airlines: Lightweight, compostable solutions for high-volume service.

Considerations before purchase:

Buyers should evaluate certification (EN13432/ASTM D6400), lid-lock design, thickness for heavy-duty use, and supplier capacity. Choosing a partner like Bioleader® ensures consistent quality, bulk availability, and compliance with international markets.

Trend Insight:

In 2025 and beyond, sugarcane bagasse trays with lids are not just replacing plastics—they are setting a new benchmark for sustainable food packaging alternatives, combining eco-benefits with real-world performance.