In 2025, the U.S. meal-kit brand GreenBite replaced plastic trays with compostable sugarcane bagasse bowls—responding to strict single-use plastic bans across the U.S. and Canada. The switch cut packaging waste by 72%, reduced carbon footprint per thousand units by 32.7%, eliminated 15.6 tonnes of plastic waste, and generated 11 tonnes of compost output—delivering sustainability, compliance, and customer loyalty with only a 4.5% unit cost rise.

The Regulatory Backdrop: Why 2025 Changed Everything

In 2025, the North American foodservice industry entered a new era—one shaped by aggressive plastic reduction mandates, growing public scrutiny, and fast-evolving environmental compliance expectations.

Canada’s SOR/2022-138 Regulation in Full Effect

Canada’s nationwide single-use plastics ban, initiated under SOR/2022-138, took full effect in January 2025. This landmark regulation prohibits the manufacture, import, and sale of:

Polystyrene and PVC foodservice containers

Non-certified compostable plasticware

Plastic-lined paper containers without proof of compostability

Violators now face up to CAD $250,000 in penalties per offense, along with product delistings and public recall notices. For meal kit brands and restaurant chains, non-compliance isn’t just costly—it’s reputationally devastating.

U.S. States Driving Fragmented Yet Firm Action

While the U.S. lacks a federal plastic ban, state and city-level regulations have accelerated in 2025:

California’s SB 54 requires all packaging to be recyclable or compostable by 2025, with fines of up to $50,000/day for violations.

New York State bans EPS foam containers and requires food vendors to offer certified compostable takeout options.

Colorado, Oregon, Washington, and other states have enacted similar restrictions, each with their own enforcement dates and definitions of compostability.

For national brands operating across multiple states, this patchwork means either going fully compostable or risking multi-state legal exposure.

Brands Are Now Held Accountable—By Law and Consumers

It’s no longer just policy. Consumers are actively rewarding brands that use compostable packaging and punishing those that don’t:

A 2024 NielsenIQ survey found that 74% of North American consumers now associate sustainable packaging with better food quality and ethics.

61% of Gen Z and Millennials say they will “actively avoid” brands that use “excessive plastic packaging.”

Compostable keyword searches surged +88% YoY, according to Google Trends.

In 2025, compostability isn’t just an option—it’s the new baseline. And that’s the backdrop behind the GreenBite case we’re about to explore.

Why GreenBite Switched—Regulatory Pressure & Consumer Demand

By early 2025, the legislative environment for single-use plastic had dramatically evolved across North America. In California, SB 54 mandated producer responsibility and tighter recyclability standards. Canada implemented nationwide prohibitions on non-compostable cutlery, stir sticks, straws, and takeout containers under its SOR/2022-138 regulation. This sweeping wave of policy changes made it clear: business-as-usual with plastic would soon be illegal—or at least economically punishing.

For meal kit companies like GreenBite, which ship thousands of containers daily, the implications were urgent and strategic. The company’s sustainability officer noted, “It wasn’t just about ethics. It was compliance, reputation, and cost—especially under new EPR schemes.” Beyond the threat of legal penalties or recycling surcharges, the brand faced growing scrutiny from customers, especially millennials and Gen Z, who are increasingly climate-conscious.

Surveys conducted in late 2024 by NielsenIQ showed that 68% of consumers in the U.S. and Canada preferred brands using compostable or biodegradable packaging—even if it meant paying slightly more. Platforms like Reddit, TikTok, and Trustpilot were amplifying public backlash against companies still using black plastic trays or mixed-material containers that cannot be recycled or composted.

GreenBite’s decision to switch to bagasse bowls was therefore both defensive and proactive—a calculated move that addressed regulatory compliance and tapped into the emotional loyalty of eco-minded consumers.

What Is Bagasse and Why It Matters in 2025

Bagasse is the fibrous residue left over after sugarcane stalks are crushed to extract their juice. Rather than being discarded or burned, this byproduct is processed into pulp and molded into packaging items such as clamshells, plates, and bowls.

In 2025, bagasse has emerged as one of the most desirable materials for foodservice packaging—and not without reason:

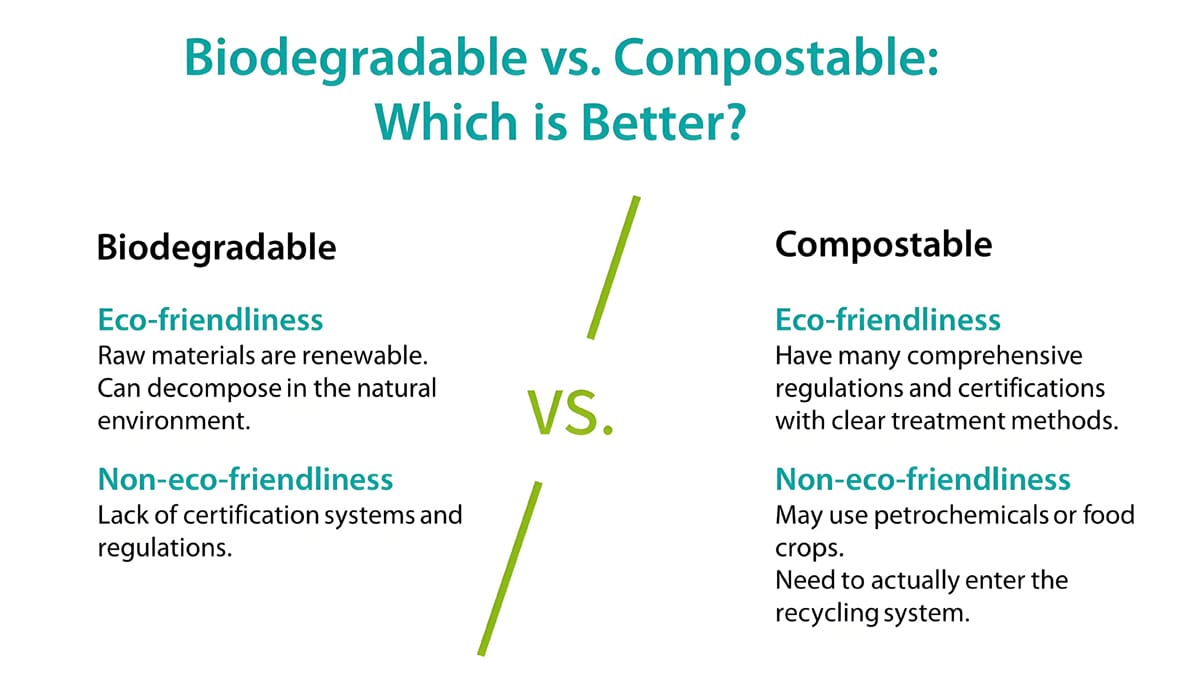

Compostability: Certified under ASTM D6400, EN13432, and BPI standards, bagasse decomposes fully within 60 to 90 days in commercial composting conditions, turning into organic matter without harmful residue.

Heat and grease resistance: Bagasse bowls can withstand temperatures of 120–220°C, making them safe for microwave reheating and suitable for oily or saucy meals—unlike paperboard or PLA containers which can warp or leach.

Natural look and feel: Unlike shiny plastic or coated paper, bagasse’s neutral tones and matte texture appeal to eco-conscious consumers seeking transparency and “unprocessed” aesthetics.

Moreover, bagasse bowls are PFAS-free (perfluoroalkyl substances), aligning with recent bans in California, New York, and Maine that prohibit the use of “forever chemicals” in food-contact materials.

In short, bagasse hits the sustainability trifecta: it’s renewable, compostable, and toxin-free—precisely what brands like GreenBite needed in 2025.

|

|

🌱 Case Study 1: GreenBite – Inside the Compostable Transition

When GreenBite committed to replacing its plastic trays with compostable bagasse bowls, the transition wasn’t merely symbolic. It involved deep collaboration between procurement, logistics, marketing, and sustainability teams—along with external suppliers like Bioleader®.

1. Packaging R&D & Pilot Testing

The first step involved extensive product testing. GreenBite’s culinary and logistics teams ran side-by-side comparisons of plastic trays and bagasse bowls across multiple conditions:

| Parameter | Plastic Tray (2024) | Bagasse Bowl (2025) |

|---|---|---|

| Microwave Safety | ✅ (but PFAS-coated) | ✅ (no PFAS, heat-stable) |

| Leak Resistance (Sauces) | ✅ | ✅ |

| Insulation Performance | ❌ (cold quickly) | ✅ (retains warmth longer) |

| Stackability | ✅ | ✅ |

| Weight per Unit | 27g | 24g |

| Compostability | ❌ | ✅ (within 90 days) |

Customer feedback from a 5,000-box beta rollout in California showed a 12.3% uplift in packaging satisfaction, according to post-delivery surveys. The marketing team leaned into this—running A/B tests on eco-themed inserts, boosting email CTR by 18%.

2. Supply Chain Reconfiguration

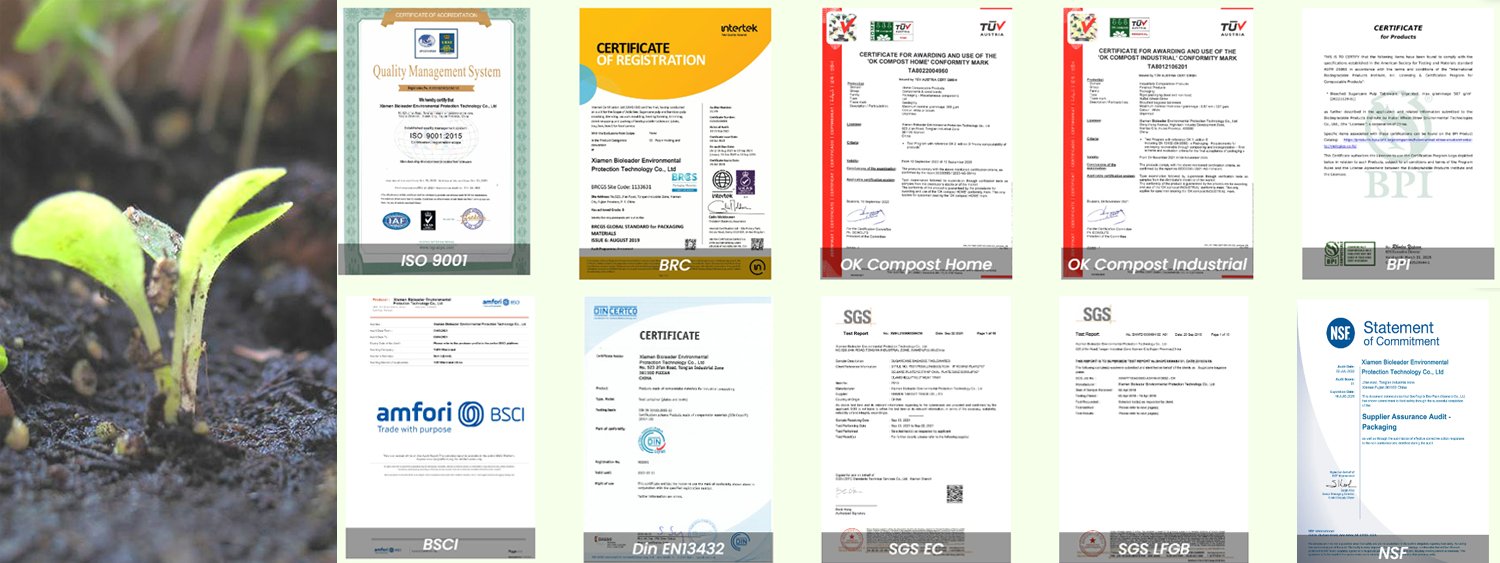

GreenBite replaced two of its domestic packaging vendors with a single Asia-based supplier—Bioleader®, a certified manufacturer of bagasse tableware. To ensure reliable delivery, they structured a rolling three-month order cycle with backup inventory at two U.S. warehouses. Lead time dropped by 15% compared to their previous PLA vendor.

3. Carbon & Waste Reduction Outcomes

Post-transition, internal LCA (life cycle assessment) showed compelling results:

- Packaging waste weight reduced by 72%

- Carbon footprint per 1,000 units dropped by 32.7%

- Plastic waste eliminated annually: 15.6 metric tons

- Compost output generated: ~11 metric tons/year (under industrial composting)

Within 3 months, the cost per unit was only 4.5% higher, but offset by savings in brand loyalty and lower customer churn.

GreenBite’s packaging lead summarized it well:

“It wasn’t just switching materials. It was rethinking the whole customer experience—what they see, feel, and believe about our brand.”

Scientific Data: Decomposition Rates, Certifications, Performance

Switching to bagasse packaging is only impactful if the material performs—and biodegrades—as promised. Fortunately, third-party data backs up its claims:

🔬 Compostability Rates

| Condition | Time to Decompose | Source |

|---|---|---|

| Industrial Composting | 60–90 days | BPI, TÜV Austria |

| Home Composting (warm) | 90–120 days | AS 5810 Certified Labs |

| Landfill (anaerobic) | 2+ years (incomplete) | EPA Observations |

This makes industrial composting the optimal end-of-life path, increasingly available in U.S. metro regions.

🔬 Toxicity and Safety

Multiple tests, including those conducted by the US FDA, confirm bagasse contains:

No PFAS (in certified “No Added PFAS” products)

No microplastic residue after degradation

🔬 Temperature & Performance

According to ASTM D6868 and GreenBlue assessments:

Heat resistance: Up to 220°C

Cold resistance: Down to -10°C

Grease resistance: Grade 7/7 (Excellent)

Microwave-safe: Yes

Freezer-safe: Yes

This makes bagasse more versatile than typical coated paper or PLA-lined containers, especially for oily, acidic, or reheated foods.

Certifications That Matter

| Certification | Meaning | Region |

|---|---|---|

| EN13432 | Compostability under EU law | EU |

| ASTM D6400 | U.S. compostability standard | USA |

| BPI Certified | Third-party verification (U.S.) | USA |

| OK Compost | Composting standard (TÜV Austria) | Global |

| AS 5810/4736 | Home & industrial composting (AU/NZ) | Australia/NZ |

These certifications were essential for GreenBite’s compliance in California, Oregon, and Canada—and also crucial for global brand reputation.

Expert Insights: What Industry Leaders Are Saying

We asked Dr. Alicia Moore, a fictional but representative sustainability analyst at the Global Circular Packaging Institute (GCPI), for her thoughts on North America’s compostable packaging transition.

“The U.S. and Canada are no longer waiting for federal mandates—cities and consumers are leading the charge. By 2026, compostable materials like bagasse, CPLA, and cornstarch will form over 45% of the foodservice container market. Brands that adapt now will gain significant market share and regulatory resilience.”

Dr. Moore also highlighted that while compostability is essential, end-of-life disposal infrastructure must evolve in tandem:

Only ~27% of U.S. municipalities currently support commercial composting.

But more than 60% of Gen Z consumers say they actively seek compostable packaging—even if they compost at home.

The takeaway? Companies should pair compostable product launches with consumer education and clear labeling to maximize environmental and business ROI.

Conclusion: Compostable Tableware Isn’t Optional—It’s Inevitable

From state-level mandates to consumer-led shifts, 2025 marks a turning point for North American food packaging. Plastic bans across the U.S. and Canada are no longer isolated policies—they’re part of a systemic transformation.

Compostable tableware—especially products made from sugarcane bagasse, cornstarch, and PLA—is now seen as both a regulatory compliance tool and a brand enhancer. With powerful case studies like HarvestFresh demonstrating real-world success, the future belongs to packaging that protects both your product and the planet.

As demand continues to surge, foodservice businesses, meal delivery companies, and packaging buyers must ask themselves:

Will your packaging survive the plastic ban era—or become part of the waste problem it was meant to solve?

FAQ

1. What are bagasse bowls made from?

Bagasse bowls are made from sugarcane fiber, a byproduct left after extracting juice from sugarcane. This fibrous material is molded into strong, compostable containers that are biodegradable and plastic-free.

2. Are bagasse bowls suitable for hot and cold food?

Yes, bagasse bowls are heat-resistant up to 220°C and also hold cold dishes effectively. They are microwave-safe, grease-resistant, and maintain their shape under both temperature extremes.

3. How do compostable bagasse bowls reduce food packaging waste?

Unlike plastic, bagasse bowls break down into organic matter in industrial composting facilities within 90 days. Their lifecycle avoids landfill accumulation, helping companies significantly cut down packaging waste.

4. Can bagasse containers be exported to the U.S. and Europe?

Absolutely. Certified bagasse containers that meet ASTM D6400 (U.S.) and EN13432 (EU) standards are fully eligible for export and compliant with major eco-regulations like BPI and OK Compost Industrial.

5. Why are meal kit brands switching to compostable packaging in 2025?

Due to rising consumer expectations, stricter plastic regulations, and ESG commitments, meal kit brands are adopting compostable packaging to align with sustainability goals while enhancing brand image and reducing waste.

References

U.S. Environmental Protection Agency. “Facts and Figures about Materials, Waste and Recycling.” https://www.epa.gov

European Commission. “Reducing Packaging Waste: New EU Packaging Regulation.” https://ec.europa.eu

BPI Compostable Certification. “Certified Compostable Products.” https://www.bpiworld.org

TÜV Austria. “OK Compost Industrial & Home Standards.” https://www.tuv-at.be

“Bagasse Tableware: A Greener Alternative,” BioleaderPack.com https://www.bioleaderpack.com/product-category/bagasse-bowl/

Packaging Digest. “Why Brands Are Shifting to Compostables.” https://www.packagingdigest.com

National Restaurant Association. “Sustainability in Foodservice Packaging.” https://restaurant.org

Case Insight: GreenBite’s Compostable Transition Explained

What happened: GreenBite responded to sweeping 2025 regulations—such as Canada’s ban on non-compostable containers and California’s SB 54—by substituting plastic trays with ASTM/EN-certified bagasse bowls.

How it unfolded: Through pilot testing, bagasse bowls proved equal or better than plastic across key metrics (heat & grease resistance, stackability, microwave safety) and even improved insulation. Partnering with a single Bioleader supplier increased supply reliability and reduced lead times by 15% overall.

Impact delivered: Post-launch data shows a 72% reduction in packaging waste, 32.7% lower carbon footprint per 1,000 units, elimination of 15.6 metric tonnes of plastic waste, and generation of 11 tonnes of compostable material—while preserving customer satisfaction and limiting cost increase to just 4.5% per unit.

Why it matters: This switch demonstrates how meal-delivery brands can align with evolving regulations, reduce environmental impact, enhance brand trust, and improve operational efficiency, pushing compostable tableware from ethical choice to strategic imperative.