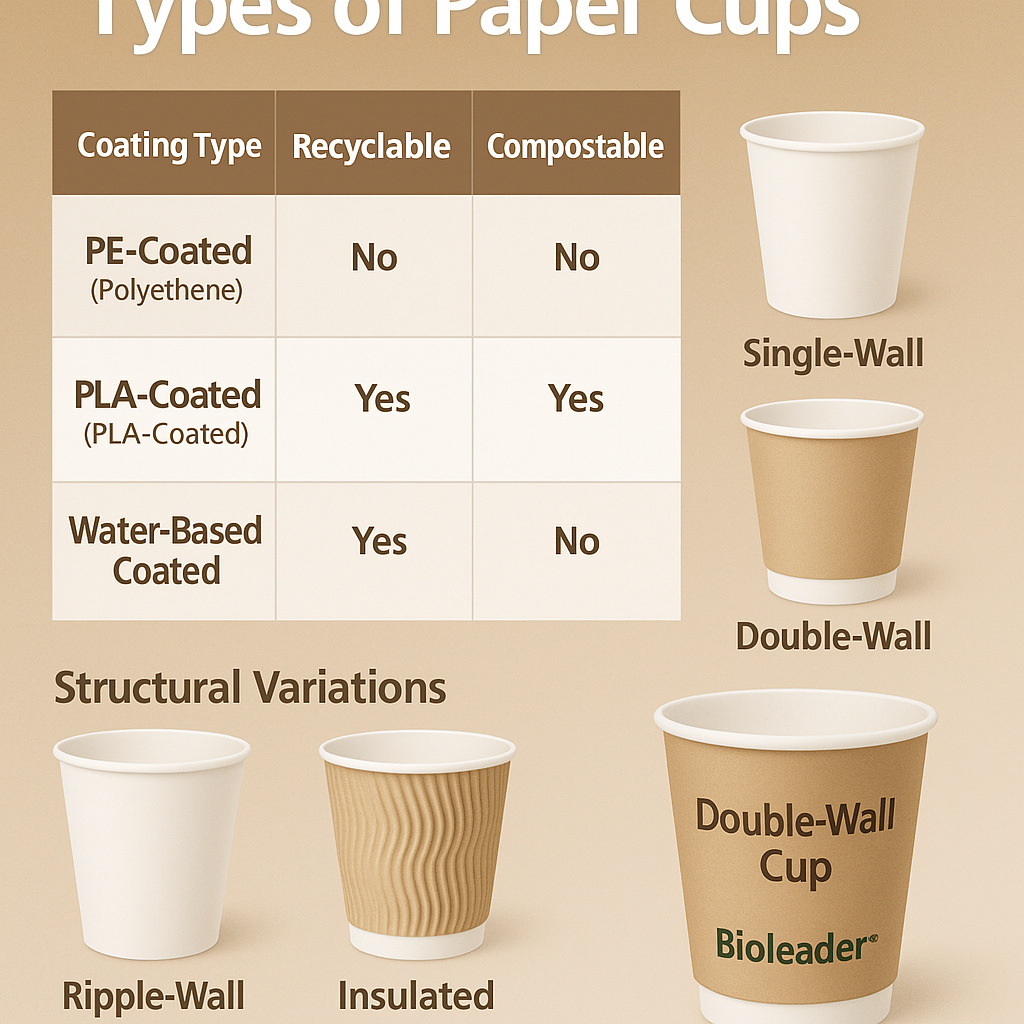

Modern paper cups fall into three primary coating systems—PE-coated (traditional), PLA-coated (compostable), and water-based coated (plastic-free).

These materials differ in recyclability, compostability, regulatory acceptance, and consumer safety.

Understanding their structural variations (single-wall, double-wall, ripple-wall, insulated designs) helps businesses choose the right solution for compliance, sustainability goals, and brand experience across global markets.

Paper cups are one of the most widely consumed food-contact packaging products in the world, with more than 500 billion units used annually across cafés, fast-food chains, hotels, airlines, and takeaway platforms. What was once a simple disposable item has now evolved into a highly regulated, sustainability-driven category shaped by environmental laws, consumer expectations, and rapidly advancing material technologies.

In 2025, the three dominant coating systems—PE, PLA, and water-based coatings—represent not just different technical approaches but different compliance paths, cost structures, recycling outcomes, and brand positioning strategies. Understanding these distinctions is now essential for any foodservice operator, beverage brand, or packaging distributor serving international markets.

This article provides one of the most comprehensive overviews available online, integrating global regulatory shifts, structural variations, expert opinions, and real-world applications to help businesses select the right paper cup solution for the next decade.

1. Why Paper Cup Materials Matter More Than Ever

1.1 Environmental pressure meets mass consumption

Paper cups are used in staggering quantities. Research from the Ellen MacArthur Foundation shows that over 97% of PE-lined cups end up in landfills because traditional recycling facilities cannot separate the plastic layer from the paper fiber effectively. As countries introduce landfill taxes, EPR fees, and plastic penalties, conventional paper cups are becoming economically and environmentally challenging for businesses.

1.2 Regulatory changes accelerate material innovation

Multiple regions are phasing out or financially penalizing cups that contain plastics, even if the plastic is part of the coating layer:

EU SUPD (Single-Use Plastics Directive) restricts PE-lined cups and encourages plastic-free or compostable alternatives.

Canada’s Single-Use Plastics Prohibition Regulations target difficult-to-recycle food packaging.

Japan’s Plastic Resource Circulation Act incentivizes water-based coatings due to recyclability advantages.

Singapore 2025 packaging framework pushes compostable and plastic-free systems for takeaway operators.

These policies mean choosing the wrong cup material may restrict your ability to sell, export, or even distribute products in certain regions.

1.3 ESG reporting turns packaging into brand identity

Global brands now publish packaging sustainability targets—Starbucks, McDonald’s, Pret A Manger, and Costa Coffee have all committed to compostable or recyclable paper cups. Packaging has shifted from a “cost item” to a strategic sustainability asset, influencing customer sentiment and investor decision-making.

2. Deep Dive into the Three Major Coating Systems

2.1 PE-Coated Paper Cups: The Industry Workhorse, Now Under Pressure

PE-coated cups remain dominant in many markets due to:

Low production cost

Mature manufacturing infrastructure

Strong performance in both hot and cold beverages

However, the drawbacks are increasingly difficult to ignore:

Environmental drawbacks

PE acts as a barrier layer that prevents paper fibers from separating during pulping, making recycling extremely challenging. Only 1–3% of PE cups are recycled globally—mostly in specialized pilot facilities.

Regulatory risks

PE coating is considered a conventional plastic, triggering restrictions and fees in many jurisdictions. For export-oriented businesses, PE cups risk non-compliance.

When PE cups still make sense

Cost-sensitive domestic markets

Hot beverage vendors without sustainability requirements

Clients operating in regions without plastic mandates

PE cups are not disappearing, but they are losing ground as countries set circular packaging targets.

2.2 PLA-Coated Paper Cups: The Global Standard for Compostability

PLA coating is made from corn starch or natural plant sugars. This bio-based polymer meets EN13432 and ASTM D6400 compostability criteria.

Why PLA is gaining momentum

Produces 60% fewer greenhouse gas emissions compared to petroleum plastics

Can biodegrade in industrial composting facilities

Recognized internationally as a compostable material

Suitable for coffee, tea, juices, smoothies, and most beverage applications

Real-world adoption

Widely used in Europe’s eco cafés

Mandated by various procurement programs in Canada and the U.S.

Approved for use by many global airline catering providers

Limitations to consider

PLA is not designed for backyard composting and requires high-temperature industrial composting. In regions without such facilities, disposal pathways may be limited.

Nevertheless, PLA remains the most commercially practical sustainable upgrade for brands transitioning away from PE.

2.3 Water-Based Coating Paper Cups: The Future of Plastic-Free Packaging

Water-based coatings are the most significant breakthrough in paper cup technology in 20 years.

What makes water-based cups special?

0% plastic—fully plastic-free

Compatible with traditional paper recycling mills

PFAS-free formulation aligns with upcoming chemical safety regulations

Suitable for hot and cold beverages

Rapid adoption among premium coffee chains

Regulatory advantages

Many European countries classify water-based cups as recyclable paper, enabling:

Lower EPR fees

Higher recycling rates

Stronger sustainability certifications

Market movement

Japan is leading the movement: by 2025, over 40% of major cafés adopted water-based cups as part of national recycling efforts.

Cost perspective

Water-based cups cost the most to manufacture, but the long-term sustainability and compliance benefits outweigh the price for many brands.

3. Structural Engineering: How Paper Cup Design Influences Functionality

Different structures significantly change customer perception and beverage performance.

3.1 Single-Wall Paper Cups

Ideal for cold drinks or cost-sensitive operations.

Best print surface for brand visuals.

Most efficient in production and logistics.

3.2 Double-Wall Paper Cups

Two-layer construction creates a heat shield.

Often chosen by café chains selling premium hot beverages.

Improves brand positioning with a more substantial feel.

3.3 Air-Pocket Insulated Paper Cups

The hollow gap between layers makes them the highest-performing hot beverage cup.

Popular in Western specialty cafés where customer experience is paramount.

3.4 Ripple-Wall Paper Cups

The corrugated exterior provides:

Strong insulation

Anti-slip grip

A distinctive, artisanal appearance

Excellent for takeaway coffee.

3.5 Embossed Paper Cups

Features a textured grip and premium tactile experience.

Allows brands to differentiate through touch as well as visuals.

4. Global Regulatory Trends Shaping Material Selection

Europe

Aggressive transition toward plastic-free materials

Water-based coating preferred due to recyclability

PLA accepted only when composting access is documented

North America

Canada heavily restricts PE

U.S. states introduce compostability certifications (BPI, CMA)

Asia-Pacific

Japan: recycling-focused; water-based coatings accelerating

Singapore: pro-compostability policy favors PLA and water-based systems

South Korea: tightening PFAS and plastic compliance rules

Middle East

UAE, Qatar, and Saudi Arabia are adopting sustainability procurement standards favoring compostable or recyclable cups for foodservice operations.

Businesses operating internationally should treat material choice as a compliance decision, not merely a packaging decision.

5. Expert Insights from Packaging Engineers & Sustainability Specialists

Dr. Lina Kovacs, EU Materials Science Researcher

“Water-based coatings resolve the biggest technical barrier in paper cup recycling. Within 5–7 years, they will likely become the regulatory baseline in Europe.”

David Chan, Asian Foodservice Sustainability Consultant

“PLA remains the optimal transitional material: scalable, internationally recognized, and suitable for brands upgrading from PE without drastically affecting cost structure.”

Bioleader® Technical Team

“Brands should not evaluate cup materials only based on cost. Consider regulatory readiness, product safety, heat performance, and consumer perception. The right choice improves both compliance and customer satisfaction.”

6. Application Scenarios: Which Cup Fits Which Business Model

Coffee Chains

→ Double-wall / ripple-wall + PLA or water-based

Improves heat insulation and elevates brand experience.

Bubble Tea & Juice Shops

→ Single-wall + PE or PLA

Cost-efficient, good for high-volume cold beverages.

Hotels, Catering, Airlines

→ Embossed or hollow insulated

Premium feel improves brand consistency.

Export Distributors

→ Prefer PLA or water-based to meet global compliance.

7. Bioleader® Paper Cup Solutions: Real-World Alignment with Global Trends

Bioleader® offers:

PE, PLA, and water-based coatings

Full range of single-wall, double-wall, ripple-wall, hollow insulated, and embossed cups

Compliance with EN13432, ASTM D6400, BPI, LFGB, FDA

Custom printing and OEM manufacturing

Experience supplying to EU, U.S., GCC, ASEAN markets

For brands planning global expansion or sustainability transformation, a manufacturer like Bioleader® provides essential technical guidance and stable, regulation-ready production capacity.

8. How to Choose the Right Cup: A Strategic Framework

Check local and export regulations

Define beverage type and temperature

Align cup material with ESG goals

Optimize branding and printing needs

Evaluate long-term compliance risk

Select a partner capable of PLA & water-based manufacturing

Paper cups are no longer commodities—they shape brand identity, compliance readiness, and sustainability performance.

How to Choose the Right Paper Cup: Insights, Options & Market Trends

How do coating materials influence sustainability and compliance?

Coatings define whether a paper cup is recyclable, compostable, or classified as a plastic product under global regulations.

PE coatings are durable but challenging to recycle; PLA coatings enable certified compostability; water-based systems deliver plastic-free, PFAS-free performance aligned with emerging laws in the EU, Japan, and Canada.

Why are brands transitioning toward PLA and water-based coated cups?

Governments increasingly penalize PE-lined cups through EPR fees, landfill taxes, or outright bans.

At the same time, consumers prefer packaging that is safe, non-toxic, and visibly sustainable.

This pushes foodservice brands, cafés, and international distributors to adopt compostable or recyclable solutions that strengthen ESG reporting and export readiness.

What structural options shape customer experience?

Single-wall cups optimize cost and printing clarity; double-wall and ripple-wall designs improve insulation for hot beverages;

hollow insulated and embossed cups enhance premium brand perception.

Cup structure determines not only hand-feel and safety but also how customers perceive beverage quality.

What are the key considerations for buyers?

Businesses should evaluate regulatory requirements, beverage temperature, brand sustainability goals, and total cost of ownership—including compliance risks.

For exporters, PLA and water-based coatings offer lower regulatory friction across 2024–2030 global plastic-reduction policies.

Industry Trend Insight:

The global shift is unmistakable: PE-lined cups are declining; PLA-coated cups are now the mainstream sustainable choice; and water-based coated cups are becoming the preferred solution for markets that demand full recyclability and plastic-free certification.

Material choice now influences brand trust, legal compliance, and long-term competitiveness in the foodservice industry.

FAQ: Popular Questions About Paper Cups

1. Are paper cups recyclable?

Water-based coated cups are the easiest to recycle. PE-lined cups require specialized processing, while PLA cups must enter industrial composting facilities.

2. What is the most eco-friendly type of paper cup?

Water-based coated cups are considered the most sustainable because they are plastic-free, PFAS-free, and compatible with mainstream paper recycling systems.

3. Can PLA paper cups hold hot drinks?

Yes. PLA-coated cups typically tolerate temperatures up to 85°C (185°F), making them suitable for most hot beverages like coffee or tea.

4. Are PE-coated paper cups being phased out?

Several countries—including the EU, Canada, and Singapore—are restricting PE-lined cups due to poor recyclability, accelerating the shift to PLA and water-based coatings.

5. Which paper cup structure is best for hot coffee?

Double-wall, ripple-wall, or insulated hollow cups offer superior heat protection and comfort, making them ideal for specialty coffee and takeaway services.