In an era where sustainability is no longer a buzzword but a mandate, big brands are taking bold steps to reduce their environmental footprint. One such milestone came when McDonald’s Japan announced its switch from plastic and foam packaging to a more sustainable solution: bagasse, the fibrous byproduct of sugarcane. This move is far more than a regional adjustment—it reflects a growing global shift in how foodservice giants think about packaging, waste, and brand responsibility.

Yes, it’s heat-resistant, leak-proof, and suitable for both hot tacos and chilled sides.

In industrial composting conditions, bagasse trays decompose within 60–90 days. In home composting systems, the breakdown may take 90–120 days, depending on factors like moisture, microbial activity, and temperature.

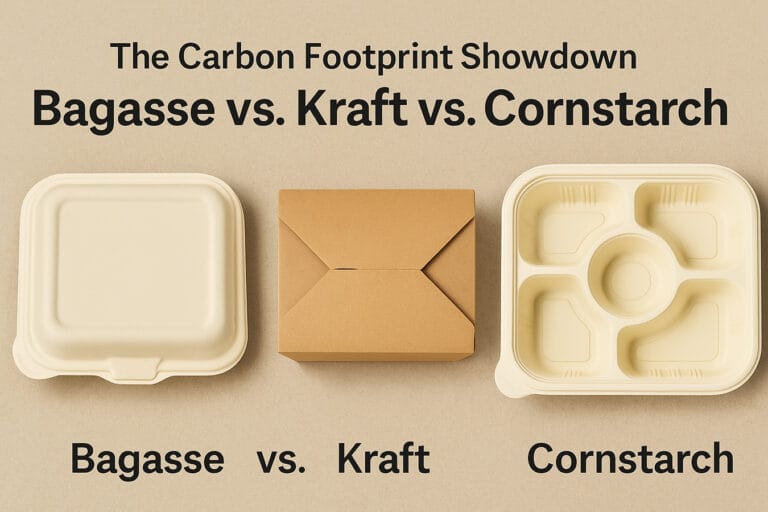

Takeaway containers are made from a variety of materials including sugarcane bagasse, kraft paper, PLA bioplastics, PP plastic, and aluminum , bagasse food container exporter. For eco-friendly applications, compostable bagasse and PLA are the most sustainable choices , bagasse food container exporter.

Global brands are switching to compostable materials to meet plastic ban regulations, improve their sustainability image, and appeal to eco-conscious consumers.

McDonald’s Japan phased out plastic containers to reduce marine pollution, meet its net-zero emission goals, and comply with increasing consumer demand for sustainable packaging — bagasse food container exporter.

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

Get the Catalogue Products List & Contact Us Now! 👉

📧 Email : [email protected]

📲 WhatsApp : +86-15980856610

🟢 Wechat : bioleader

📍 Add : No.39 Xinglong Road, Xiamen, China

Copyright © 2015–2025 Xiamen Bioleader Environmental Protection Co., Ltd | All Rights Reserved. Privacy Policy | AI Policy | Sitemap

WhatsApp us