Eco-Friendly Food Packaging for Foodservice | Sustainable Containers, Plates & Bowls by Bioleader®

Eco-friendly food packaging for foodservice is a procurement-level material strategy focused on lower impact, reduced plastic reliance, and real-world performance. This page curates responsible options across containers, plates, and bowls—using sugarcane fiber (bagasse pulp), paper-based formats, cornstarch options, and PLA/CPLA—so buyers can select the right packaging set for consistent daily service.

- Bioleader® Biodegradable Tableware

- Showroom

- Eco-Friendly Food Packaging | Sustainable Containers, Plates & Bowls for Foodservice | Bioleader®

Bioleader® Product Showcase & Category

Sugarcane Bagasse Tableware Series

Paper Cups & Bowls | Food Paper Packaging Series

Cornstarch Tableware Series

What Eco-Friendly Means in Foodservice Procurement

In foodservice, “eco-friendly” is not a single label—it is a buyer decision framework that balances impact reduction with operational stability. An eco-friendly packaging program typically aims to:

Reduce plastic dependency across core serving items (containers, plates, bowls)

Use responsible materials that align with brand values and market expectations

Maintain service performance—speed, stacking, grease tolerance, and presentation consistency

Match a realistic end-of-life path based on how waste is handled in your destination market

This page is built for buyers who want a clear, practical way to standardize packaging choices without compromising service flow.

Material Options (Choose by Menu, Not by Labels)

The most effective eco-friendly programs select materials by menu heat level, oil content, holding time, and service style—not by buzzwords. Below is how foodservice teams typically evaluate common responsible material options:

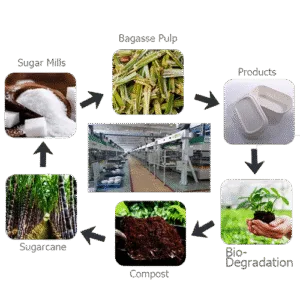

Sugarcane Fiber (Bagasse Pulp)

A fiber-forward choice for hot meals and heavier portions. Molded sugarcane fiber formats are commonly selected for rigidity, clean presentation, and reliable handling in fast service lines and event catering.

Paper-Based Formats

A go-to option for brand-facing presentation and standardized operations. Paper-based packaging supports strong printing and consistent appearance, often used across a wide range of service scenarios depending on food type and holding time.

Cornstarch Options

Plant-based formats used in selected high-volume SKUs where lightweight handling and cost control matter. Often considered when buyers want a plant-based alternative for everyday service items.

PLA / CPLA

Plant-based bioplastics chosen when a specific functional need exists—such as clarity/visibility (PLA) or higher heat tolerance for utensils and accessories (CPLA). Useful in programs where presentation or handling requirements make traditional materials less suitable.

Performance Standards Buyers Actually Care About

Eco-friendly packaging must perform in real kitchens. Procurement teams typically prioritize the following standards to prevent service failures:

Grease & Moisture Tolerance

Maintains structure for saucy, oily, or moisture-heavy foods during prep and service.Heat Handling & Shape Stability

Supports hot filling and warm holding without softening or warping in normal foodservice workflows.Stackability & Denesting Speed

Reduces prep friction—faster grabbing, less sticking, smoother plating and packing.Portion Consistency

Standard sizes and stable forms help control serving cost and presentation across locations.Presentation Quality

Clean surfaces, uniform color/texture, and a brand-ready look for modern foodservice standards.

Quick Decision Table for Foodservice Programs

Use this table to match packaging choices to common foodservice scenarios. (You can convert this into an Elementor table for snippet-friendly formatting.)

| Service Scenario | Primary Need | Recommended Material Direction | Typical Formats |

|---|---|---|---|

| Hot entrées & saucy dishes | Rigidity + grease tolerance | Sugarcane fiber (bagasse pulp) focus | Containers, plates, bowls |

| Salads, sides, mixed menus | Presentation + standardization | Paper formats or molded fiber depending on holding time | Bowls, plates, trays |

| Catering & events | Stackability + fast plating | Fiber-forward formats designed for speed | Plates, bowls, compartment trays |

| Café/light meals | Brand look + workflow simplicity | Paper formats and selected plant-based options | Bowls, plates, small containers |

| Visibility-first items | Clear presentation | PLA where clarity is required | Cold cups/lids and selected formats |

Product Certifications & Compliance

Bioleader® supports food-contact safety and program compliance documentation based on material line, item code, and destination market. For buyer audits and import checks, we can align the correct document pack for the SKUs you select. Share your target country and item list, and our team will prepare the matching compliance files for your foodservice program.

(If your project requires compostability-focused claims and documentation, please refer to our Biodegradable Food Packaging page for that specific program scope.)

Custom Branding & Bulk Supply for Foodservice

For multi-location foodservice and catering buyers, consistency is the real cost-saver. Bioleader® supports bulk supply programs designed to keep packaging uniform across menu lines—containers, plates, and bowls—while offering customization options to strengthen brand presentation.

Common buyer requests include:

Assortment planning by menu (hot meals, salads, sides, event service)

Carton-level labeling and packaging presentation alignment

Stable bulk supply for repeat ordering and seasonal demand cycles

FAQs About Eco-friendly Food Packaging

1. What does eco-friendly mean for foodservice packaging?

Eco-friendly foodservice packaging focuses on reducing plastic dependency through responsible materials while maintaining performance for daily service operations.

2. Which materials are commonly used in eco-friendly packaging programs?

Common options include sugarcane fiber (bagasse pulp), paper-based formats, cornstarch options, and PLA/CPLA—selected by menu heat, oil level, and workflow needs.

3. Is eco-friendly packaging always compostable?

Not necessarily. Eco-friendly is a broader program approach; end-of-life outcomes depend on material choice, product design, and local waste handling infrastructure.

4. How do I choose packaging by menu temperature and oil content?

Match hotter, oilier foods with more rigid and grease-tolerant formats, and use paper or plant-based options where presentation and standardization are the priority.

5. Can Bioleader® support bulk purchasing across containers, plates, and bowls?

Yes. We support bulk supply across key packaging formats to help buyers standardize SKUs and keep operations consistent across locations.