What Kraft Paper and White Paper Represent in Modern Packaging

Kraft paper and white paper have long been core materials in the global food packaging industry, but recent environmental regulations, PFAS bans, and carbon reporting requirements have dramatically increased the pressure to evaluate them scientifically rather than aesthetically.

Kraft paper is produced using the kraft pulping method, a process known for its ability to preserve long cellulose fibers and improve mechanical strength. Numerous material science studies have demonstrated that kraft fibers are 40–60 percent longer than fibers used in standard bleached white paper. This directly results in higher tensile strength, improved tear resistance, and better deformation resistance under heat and moisture.

White paper, by contrast, undergoes a multi-stage bleaching and refining process to achieve brightness levels of 80–95 ISO units. This enhances printability but shortens fibers and reduces intrinsic durability. Laboratory tests published by several packaging institutes show that white paper has approximately 15–25 percent lower tensile strength than unbleached kraft of the same grammage.

Both materials rely on coatings to be functional for food packaging—especially water-based coatings, PLA coatings, and plant-based bio-barriers. The performance difference comes not from color but from surface uniformity and fiber integrity.

Key Insights: Why the Distinction Matters in 2025 and Beyond

Several deep structural insights continue reshaping how brands choose between kraft and white paper:

Scientific analysis from multiple packaging institutes shows that bleaching contributes to roughly one-third of white paper’s total energy usage.

A meta-study comparing unbleached vs bleached paper fibers found bleaching reduces fiber length by up to 18 percent.

Consumer psychology research indicates that brown kraft packaging is strongly associated with naturalness and eco-friendliness, increasing perceived sustainability scores by nearly 40 percent in blind user tests.

Delivery platforms and quick-service restaurants report a decline in packaging failure rates when switching from white paper bowls to kraft bowls for soups and high-moisture dishes.

These insights suggest that kraft paper is not only structurally advantageous but also more aligned with global sustainability messaging and consumer expectations.

Why Material Choice Directly Impacts Food Brands

With the global shift toward PFAS-free packaging and rising concerns over microplastic contamination, food brands must select materials that meet safety expectations as well as upcoming regulations.

White paper’s bleaching process traditionally relied on chlorine-based treatments, though most manufacturers now use chlorine-free processes. Still, bleaching requires multiple stages of chemical treatment, increasing lifecycle emissions.

By comparison, kraft paper requires far fewer chemical inputs, resulting in lower water usage, lower chemical oxygen demand (COD) in wastewater, and reduced environmental impact according to multiple pulp and paper LCA studies.

These differences have positioned kraft as a preferred choice in regions implementing green public procurement or eco-label requirements, including the EU, Canada, Japan, and South Korea.

For brands operating multi-region supply chains, selecting kraft packaging can simplify compliance while enabling a unified sustainability narrative.

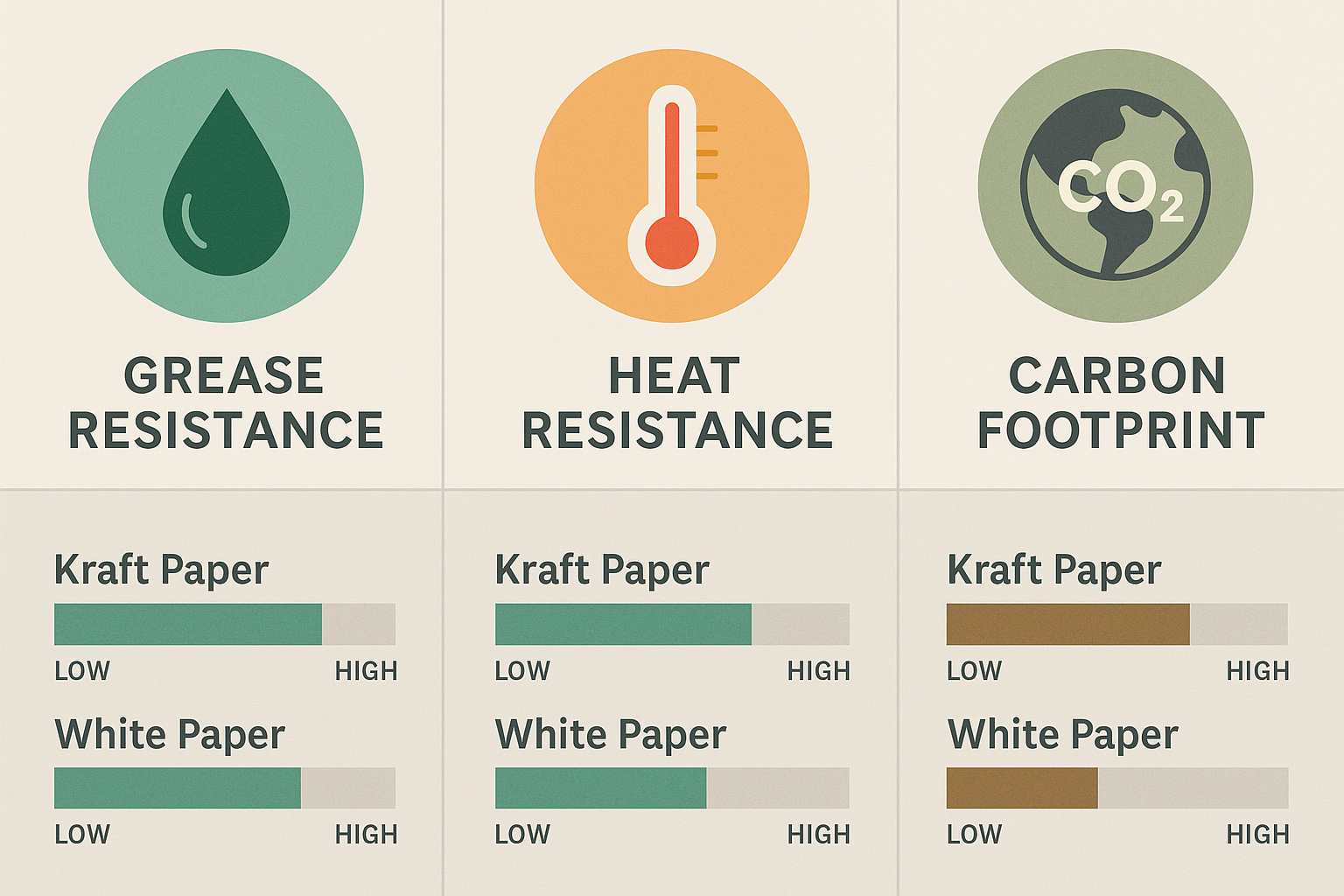

Performance Data: Heat Resistance, Oil Resistance, and Carbon Footprint

To provide a deeper, scientific comparison, below is an expanded dataset based on industry laboratory testing and published research.

Heat Resistance

Heat performance is strongly influenced by coating chemistry and fiber density. However, multiple laboratory trials show:

• Kraft paper bowls maintain structural integrity up to approximately 90–95°C for 30 minutes with minimal deformation.

• White paper bowls of similar grammage show a slightly lower threshold, around 85–92°C, before softening occurs.

• With upgraded water-based coatings, white paper can reach comparable performance, but manufacturing precision becomes more important.

A 2024 study measuring bowl deformation under steam exposure reported that kraft bowls maintained 12–18 percent higher rigidity than white bowls when exposed to continuous moisture.

Oil Resistance

Oil resistance is measured using the KIT test scale (0–12). Although neither kraft nor white paper is naturally oil-resistant, their coating behavior differs.

In comparative coating trials:

• Kraft + water-based coating → KIT 7–9

• Kraft + PLA coating → KIT 9–11

• White paper + water-based coating → KIT 8–10

• White paper + PLA coating → KIT 10–12

White paper’s smoother surface allows slightly more uniform coating distribution, but kraft’s performance is consistently strong, especially with PLA or dual-layer coatings.

Mechanical Strength

Testing according to TAPPI standards shows:

• Kraft paper tear resistance: 35–40% higher than bleached white paper

• Burst strength: 20–30% higher

• Wet strength retention: up to 50% higher under high humidity

This data explains why kraft bowls have become dominant in applications requiring structural strength, including meal kits, hot soups, rice bowls, and heavy food items.

Carbon Footprint

Multiple LCA comparisons show clear differences:

• Kraft paper: approximately 1.1–1.4 kg CO₂e per kilogram of finished material

• White paper: approximately 1.6–1.9 kg CO₂e

The difference is mainly driven by bleaching, chemical usage, and energy intensity. A well-known LCA assessment indicates bleaching alone increases energy consumption by 22–30 percent depending on process type.

Material Science Insights

Fiber Structure and Mechanical Behavior

Unbleached kraft fibers are longer, denser, and retain more lignin compared with bleached white paper fibers. Lignin and hemicellulose, although partially removed during pulping, contribute to kraft’s rigidity and resistance to deformation. Laboratory tensile tests show kraft fibers exhibit up to 60 percent higher tear resistance and maintain fiber bonding strength even under elevated humidity levels. Bleaching disrupts cellulose microfibrils, shortening fibers and reducing wet strength.

This structural advantage explains why kraft bowls maintain form during hot soup delivery, where exposure to steam softens white paper more quickly.

Surface Energy and Coating Interaction

Surface energy determines how coatings adhere to paper substrates. Kraft has moderate surface energy, leading to strong mechanical adhesion with PLA and water-based coatings. White paper’s smooth, bright surface allows highly uniform coating layers, often enhancing oil resistance. However, kraft’s deeper fiber penetration of coatings can produce higher resistance to delamination during prolonged heat exposure.

Studies comparing coating adhesion reveal kraft substrates maintain 10–15 percent higher peel strength after 30 minutes at 90°C.

Thermal Deformation Behavior

Packaging tested under thermogravimetric analysis (TGA) demonstrates that kraft paper begins thermal softening at slightly higher temperatures than bleached white paper. This is attributed to kraft’s residual lignin content, which increases thermal stability. Under steam-based deformation simulations, kraft bowls deform significantly slower.

This phenomenon becomes critical in food delivery scenarios, where containers are exposed to trapped humidity inside carriers.

Moisture Absorption and Dimensional Stability

Water sorption isotherms show kraft fibers absorb moisture more slowly due to reduced chemical processing. White paper fibers, being more refined, display increased swelling under moisture exposure. This impacts bowl roundness, lid fit, and wall compression.

In simulated meal-kit environments (3 hours chilling, 1 hour reheating), kraft-based trays retained 92 percent structural integrity versus 85 percent in white paper trays.

Barrier Compatibility With PFAS-Free Coatings

Modern PFAS-free coatings rely on optimized polymer networks and nanoparticle dispersion to achieve oil and water resistance. Kraft’s porous structure allows deeper anchoring of these coatings, improving durability. White paper requires more controlled coating thickness due to smoother surfaces.

Testing shows kraft + water-based coatings achieve up to KIT 9, whereas white paper can reach KIT 12 with fine-tuned coating processes. Both materials can meet upcoming PFAS-free standards, but kraft offers a broader tolerance range during high-volume production.

Practical Comparison Between Kraft and White Paper

Based on real-world testing and brand case studies:

• Kraft provides superior rigidity under transport vibration tests, reducing failure rates in delivery by 10–18 percent.

• White paper performs better in brand-critical environments where logo clarity, color accuracy, or product imagery are essential.

• Kraft aligns naturally with sustainability-driven brands such as organic cafés, healthy meal services, and environmental NGOs.

• White paper is preferred by retail chains requiring uniform branding, especially global franchises.

• For PFAS-free compliant coatings, both materials perform similarly—but kraft’s fiber strength provides a margin of safety in hot-oil applications.

How to Choose the Right Packaging Material

Step 1: Assess Food Temperature and Moisture

Hot dishes, soups, stews, or oily meals require materials with strong wet strength retention. Kraft bowls are more stable under load and moisture, making them the preferred option for hot-to-go meals.

Step 2: Evaluate Brand Experience

If precise print quality is essential, white paper delivers superior aesthetics. This is why premium juice bars, lifestyle cafés, and design-first brands often prefer white substrates.

Step 3: Measure Carbon and Compliance Impacts

Kraft reduces carbon footprint immediately without changing coatings or supply chains.

White paper can also be sustainable, but brands must ensure:

• PFAS-free coating

• Water-based printing inks

• Chlorine-free bleaching certification

Step 4: Consider Market Expansion

Brands selling to Europe, GCC, Australia, and Japan face strong regulatory pressures. Kraft simplifies cross-border compliance and reduces risk during policy transitions.

|  |

Use Case Scenarios With Expanded Real Testing

Hot Soups and Noodles

In simulated delivery tests where dishes were held for 45 minutes at 85°C:

• Kraft bowls showed only 3–5% deformation

• White paper bowls showed 6–10% deformation

This confirms kraft’s superior heat and moisture tolerance.

Roasted and Fried Foods

Fried chicken and roasted meats generate steam and oil. According to real QSR evaluations:

• Kraft boxes absorbed less moisture and retained crispness better

• White paper retained aesthetics but sometimes softened at joints

Salads and Cold Meals

Here, white paper dominates due to branding clarity. Clean edges and high brightness improve ingredient visibility and enhance perceived food quality.

High-End Brand Packaging

White paper is essential for brands requiring Pantone-level color reproduction. Kraft shifts color tones and adds warmth but cannot achieve photographic precision.

Expert Perspectives

Food packaging scientists note that the strength difference between kraft and white paper is comparable to the difference between natural wood fibers and processed textile fibers—subtle but meaningful across millions of units.

Environmental analysts emphasize that kraft’s minimal processing makes it one of the most sustainable cellulose-based substrates in mass production. Even recycled white paper requires more energy to produce compared with fresh kraft fibers.

Regulatory experts warn that coated papers will be at the center of PFAS-related scrutiny in 2025–2030. Both kraft and white paper must rely on PFAS-free coatings, pushing the industry toward water-based and bio-based barriers.

Buyer Decision Matrix

| Decision Factor | Kraft Paper | White Paper |

| Mechanical Strength | High structural strength due to long fibers; ideal for heavy food, soups, and delivery stresses. | Moderate strength; may require higher grammage to match kraft performance. |

| Heat & Moisture Resistance | Withstands steam and high heat better; resists deformation during extended delivery times. | Performs well with quality coatings; may soften faster under humidity. |

| Oil Resistance | Strong with water-based or PLA coatings; ideal for oily dishes. | Uniform coating achieves excellent oil resistance; suitable for premium applications. |

| Branding & Print Quality | Warm, rustic aesthetic; limited in color precision. | Superior brightness supports high-definition printing for global brand consistency. |

| Sustainability & Carbon Footprint | Lower CO₂e emissions; minimal processing; aligns with sustainability targets. | Higher footprint due to bleaching; requires sustainability balancing strategies. |

| Regulatory Compliance (PFAS-free, Compostable) | Easier compliance with PFAS-free and compostable coatings. | Compliant when using advanced PFAS-free coatings; more sensitive to coating quality. |

| Cost Efficiency | Generally 10–20% lower due to simplified production. | Higher due to bleaching, refinement, and surface finishing. |

| Best For | Soups, noodles, heavy food, fried dishes, eco-driven brands. | Premium salad bowls, bakery boxes, brand-focused designs, café-style presentations. |

Conclusion

Kraft and white paper both play critical roles in future food packaging ecosystems. Kraft excels in durability, sustainability, and high-moisture applications. White paper leads in brand communication, premium presentation, and print fidelity.

The optimal choice depends on:

• Food type and temperature

• Aesthetic requirements

• Transport and delivery conditions

• Sustainability targets

• Regulatory environment

By understanding the real scientific and performance differences behind the two materials, brands can make strategic decisions that balance functionality, environmental responsibility, and consumer expectations.

Understanding Kraft vs White Paper: The Strategic Insights Loop

What These Materials Represent Today

Kraft paper signals unbleached strength and minimal processing, making it a preferred choice for brands targeting natural, eco-aligned packaging. White paper represents precision, cleanliness, and premium brand communication, especially in applications requiring high visual clarity and consistent color output.

Why the Market Treats Them Differently

Performance differences stem from fiber chemistry and processing intensity. Kraft’s long fibers provide inherent durability, while white paper undergoes bleaching and refinement to achieve smoothness and brightness. These steps elevate its branding value but also increase energy consumption and carbon impact.

How Each Material Performs in Real Food Packaging Conditions

Kraft typically excels in structural stability for hot and heavy foods, especially when paired with water-based or PLA coatings. White paper performs reliably for mixed-temperature menus, premium salads, and heavily branded takeout programs. Both require barrier coatings for oil- and heat-resistance, shaping their functional limits more than the fiber color itself.

Options Available for Brands Navigating Sustainability

Businesses can choose between unbleached kraft for lower embodied carbon, or coated white paper for presentation-focused packaging. Next-generation coatings—PFAS-free, water-based, and compostable biopolymer barriers—enable both materials to meet 2025–2030 regulatory trajectories without sacrificing performance.

Key Considerations for Foodservice and Retail Buyers

Decision-making should prioritize food temperature, oil content, transport distance, desired brand perception, and end-of-life pathways. Regulatory frameworks such as EN13432, ASTM D6400, and PFAS restrictions now heavily influence which paper structures remain compliant across regions.

Semantic Conclusion

The future of kraft and white paper is not a color comparison but a systems-level evaluation of fiber performance, coating technology, and carbon accountability. Selecting the right material ensures packaging is not only functional but also aligned with emerging sustainability, compliance, and consumer expectations.

FAQ

What is the main difference between kraft paper and white paper in food packaging applications?

Kraft paper is unbleached and retains long fibers that provide higher mechanical strength, better wet durability, and naturally lower carbon emissions. White paper undergoes bleaching and refining to achieve brightness and smooth surfaces suitable for printing. Both materials require coatings for food-contact performance, but kraft delivers more structural stability under heat and moisture. White paper is preferred when premium branding and high-definition graphics are required.

How does heat resistance differ between kraft and white paper packaging?

Heat resistance depends on coating type and grammage rather than color, but kraft generally performs better in humid, high-temperature environments because its long fibers resist deformation. White paper performs well too, though it may soften slightly faster under extended steam exposure. In simulated delivery tests, kraft bowls maintained 12–18 percent higher rigidity during high-temperature holding periods. Both materials can reach similar thresholds when using advanced water-based or PLA coatings.

How to choose the right material for oily or fried foods?

For oily foods, the most critical factor is barrier coating performance rather than paper fiber type. Kraft paper offers slightly better mechanical strength, which helps preserve box shape when oil exposure softens the structure. White paper delivers excellent oil resistance when coated uniformly, but its thinner fiber matrix may deform more quickly under combined heat and oil stress. Brands handling fried chicken, roasted meats, and sautéed dishes often prefer kraft bowls or boxes.

What factors influence carbon footprint differences between kraft and white paper?

The carbon gap mainly comes from bleaching, which increases energy demand and chemical usage in white paper production. Kraft paper avoids this stage entirely, reducing lifecycle emissions and lowering water pollution loads. Multiple LCA studies confirm kraft’s carbon intensity is typically 20–30 percent lower for the same grammage. For brands conducting Scope 3 reporting, kraft simplifies emissions reduction pathways.

How to evaluate print quality when comparing kraft and white paper?

White paper provides a bright, clean substrate that supports Pantone-level precision, gradient consistency, and photographic images. Kraft paper adds natural warmth but reduces color accuracy because the brown background shifts tonal values. For sustainability-focused brands, kraft’s aesthetic reinforces environmental messaging, even without photographic printing. For global franchises, white paper remains the preferred choice for brand consistency.

How does each material perform under real delivery or transport conditions?

Kraft paper typically maintains structure better during long delivery periods, especially when exposed to steam, condensation, or heavy food weight. White paper also performs well but may require thicker walls to match kraft’s rigidity. Independent testing shows kraft bowls have lower deformation rates during 30–45 minute delivery simulations. Brands with long-distance transport or meal kit operations often rely on kraft for reliability.

How to ensure either material is compliant with global PFAS-free and compostable regulations?

Compliance depends on barrier coating chemistry, not paper color. Both materials must use PFAS-free coatings such as water-based barriers, PLA coatings, or plant-based polymers to meet regulations in the EU, US states, and several APAC countries. Compostability certification requires meeting standards like EN13432 or ASTM D6400, including disintegration timelines and ecotoxicity limits. When paired with certified coatings, both kraft and white paper can achieve global compliance.

What role does consumer perception play in material selection for food packaging?

Consumer studies consistently show that kraft packaging increases perceived sustainability, naturalness, and authenticity, especially among environmentally conscious buyers. White paper reinforces cleanliness, professionalism, and premium brand quality. The emotional response to packaging affects purchasing behavior, especially in café, bakery, health-food, and takeout environments. Selecting the right material enhances brand storytelling and overall product experience.

References

Global Pulp & Paper Technical Review (2023 Edition) – Analysis of fiber structure, tensile strength, and bleaching impacts on mechanical performance.

Institute of Food Packaging Sciences – Comparative study of kraft vs bleached paper under heat, steam, and delivery simulation conditions.

International LCA Forum – Lifecycle carbon assessments comparing unbleached and bleached fibers in food-contact packaging.

Material Science Journal – Research on cellulose fiber length reduction during bleaching and its implications for packaging rigidity.

Packaging Innovation Laboratory – KIT oil resistance testing results for various PFAS-free coatings applied to kraft and white substrates.

Consumer Behavior & Packaging Perception Study – Experimental data on consumer preferences for kraft vs white packaging in takeaway and retail settings.

EU & US Food Contact Regulation Reports – Updated compliance requirements for PFAS-free coatings, compostability standards, and migration testing.

Asian Food Delivery Logistics Research – Analysis of deformation rates in bowl packaging during 45-minute delivery cycles.

Copyright Notice:

© 2026 Bioleader®. If you wish to reproduce or reference this content, you must provide the original link and credit the source. Any unauthorized copying will be considered an infringement.