Water-Based Coated & Uncoated Paper Cups – Plastic-Free, Compostable Options for Drinks

Water-based coated and uncoated paper cups offer a fully plastic-free, compostable, and food-grade solution for beverage brands seeking zero-plastic packaging. Engineered with natural fibers and innovative water-dispersion barrier technology, these cups deliver reliable leak resistance and high temperature stability without relying on PE or PLA plastics. Bioleader® provides scalable wholesale supply for cafés, hotels, and beverage manufacturers transitioning to next-generation sustainable cup systems.

About Water-Based Coated & Uncoated Paper Cups

Water-based coated and uncoated paper cups represent the newest evolution in plastic-free drink packaging. Instead of using conventional PE or bioplastic linings, these cups rely on cellulose-friendly water-dispersion barrier formulations—or no coating at all—while maintaining leak resistance and food-contact safety. The technology allows cups to naturally break down during composting or pulping processes, enabling easier recycling and improved circularity. Uncoated versions are suitable for specific cold or low-moisture drinks, while water-based coated cups are ideal for daily café operations requiring enhanced durability. These solutions align with global policies targeting the reduction of single-use plastics, making them highly relevant for modern F&B brands.

Bioleader® Plastic-Free Paper Cups Top Pick

Why Choose Bioleader® Water-Based & Uncoated Paper Cups?

Water-based barrier cups and uncoated paper cups deliver a clear sustainability advantage for businesses seeking plastic-free compliance without compromising product performance. Bioleader®’s water-dispersion coating provides dependable leakproof performance for hot and cold drinks while remaining fully compostable and repulpable after disposal. Uncoated options offer a natural fiber texture and eliminate all chemical coatings for applications where moisture exposure is minimal.

Why Opt for Plastic-Free Paper Cups?

Plastic-free cups eliminate PE and PLA, reducing contamination risks in recycling streams and ensuring easier composting and repulping. They help brands meet stringent regulations targeting petrochemical-based materials.

How Water-Based Coating Enhances Leak Resistance

The water-dispersion formulation forms a micro-thin barrier that prevents seepage, withstands heat, and maintains cup rigidity—without introducing plastic films. It is ideal for daily beverage service and takeaway operations.

Key Features of Bioleader® Plastic-Free Paper Cups

Features include excellent liquid resistance, rapid compostability, zero-plastic composition, natural fiber aesthetics, and excellent compatibility with paper lids or CPLA lids.

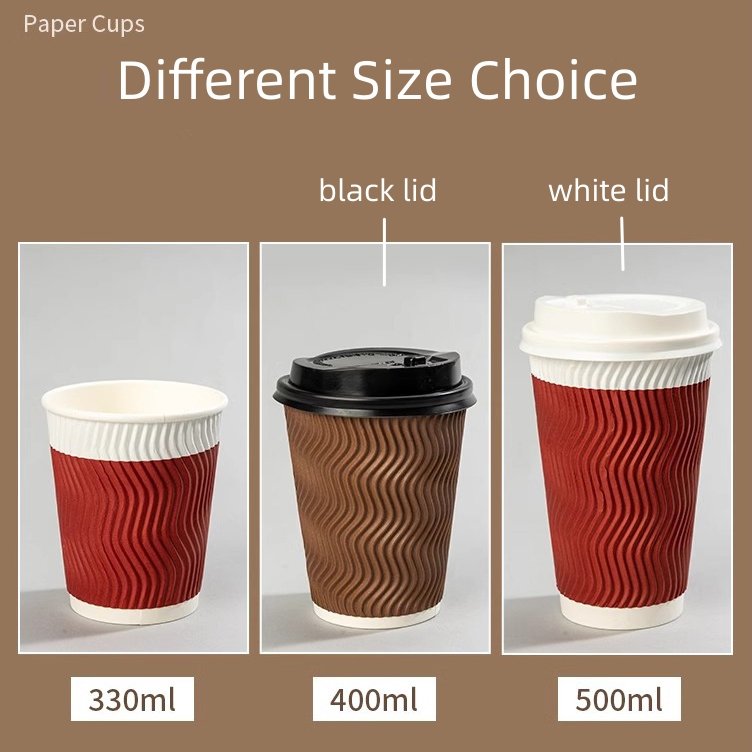

Bioleader® Water-Based & Uncoated Paper Cups — Sizes & Applications

| Type | Size Range | Capacity (oz/ml) | Application |

|---|---|---|---|

| Water-Based Coated Paper Cups | 4oz–20oz | 120–600ml | Hot drinks, coffee, tea, chocolate |

| Uncoated Paper Cups | 2.5oz–12oz | 75–360ml | Tastings, sampling, low-moisture beverages |

WB Coated Paper Cups

Water-based coated paper cups deliver reliable barrier performance without using PE or PLA plastics. The innovative water-dispersion coating creates a thin, food-grade protective layer that prevents leakage, supports hot and cold beverages, and remains fully compostable. This plastic-free technology helps brands meet advanced sustainability policies while maintaining strong cup rigidity and clean print surfaces.

Features:

Plastic-free coating, excellent leak resistance, suitable for hot and cold drinks.

Best For:

Cafés, beverage kiosks, coffee chains, eco-focused takeaway programs.

Uncoated Paper Cups

Made entirely from fiber with no coating layer, uncoated cups support absolute zero-plastic declarations and natural compostability. They are ideal for low-moisture drinks, dry servings, tastings, and applications where brands prioritize minimal processing and natural textures.

Features:

100% fiber-based, naturally compostable, authentic kraft-style appearance.

Best For:

Sampling cups, tastings, low-moisture beverages, premium eco-minimalist brands.

How to Customize Plastic-Free Paper Cups for Your Brand

Customizing plastic-free cups allows brands to elevate sustainability positioning while showcasing unique visual identity. Bioleader® offers multi-color water-based printing compatible with fiber-based cup surfaces, ensuring sharp artwork and clean color expression. Water-based coated cups support vibrant branding for mainstream cafés, while uncoated cups deliver a kraft-like, natural aesthetic favored by eco-focused businesses. With flexible MOQ and full-size coverage, Bioleader® enables scalable customization for beverage retailers, corporate cafés, and chain operators.

Logo/Colour Printing Customization Guide

We supply OEM/ODM custom-made logo/color printing based on MOQ:50,000pcs each:

Printing Area: 1: Cup’s body & bottom;

- Contact us and choose the item/size you need.

- Confirm the order with us. (Signed contract/PI)

- Design/Drawing: You issue the PDF, AI, CDR format profile, or clear logo, drawing to us, and tell us your idea or a simple design. Then we can design for you freely.

- Or we give you the blank printing drawings of which sizes/types you choose and resend them back to us after you design them.

- Finalize: We will adjust the design/drawing based on Step 3 or 4, and then you confirm it after carefully checking.

- Samples: We can issue the printing samples(if needed).

- Production: We will arrange the mass Production on time under our produce plan.

- Finished: Products finished and arrange export to you based on contract or agreement.

Paper Cups Production Process

1:Paperboard Selection: Choose the thickness, weight, and coating properties based on the order.

2:Coating: Paperboard is coated with a thin layer of plastic (PE or PLA) (for waterproof and holding liquids).

3:Printing: Flexographic printing under the desired design.

4:Cutting: Sheet cutting into flat sheets then die-cut into specific shapes use for the body of the cups.

5:Forming: Cup body formation: the edges are heated and bonded together to create a cylindrical shape. Bottom sealing: the circular bottom piece is inserted and sealed to the cup body using heat and pressure. (ensures leak-proof).

6:Rimming and Curling:Rimming: the top edge of the cup is curled to form a rim (structural strength & smooth edge for drinking). Heat Sealing: The curled rim is heat-sealed to reinforce the cup’s structure.

7:Inspection and Quality Control.

8:Packaging: Packaged into sleeves or boxes.

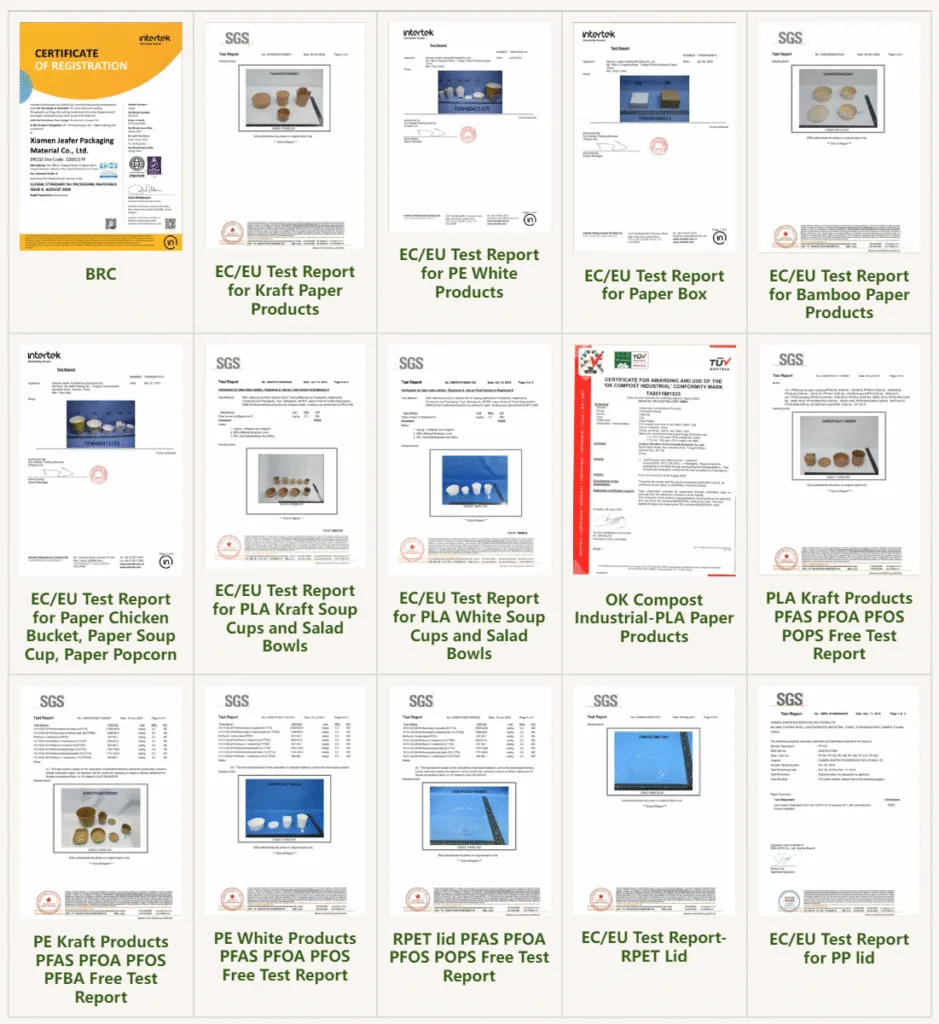

Sustainability Certifications for Our Compostable Paper Cups

Bioleader® water-based coated and uncoated cups are compliant with EN13432 and OK Compost standards where applicable, ensuring their compostability and plastic-free integrity. All materials meet FDA and LFGB food-contact requirements, guaranteeing chemical safety and zero microplastic migration. These certifications validate the cups’ suitability for markets adopting strict plastic regulations and circular packaging strategies.

BRC: Food Safety Certification for Packaging Products

EC/EU Test Report for Kraft Paper Products

EC/EU Test Report for PE White Products

EC/EU Test Report for Bamboo Paper Products

OK Compost Industrial – PLA Paper Products

PLA Kraft Products PFAS PFOA PFOS POPS Free Test Report

PE Kraft Products PFAS PFOA PFOS PFBA Free Test Report

PE White Products PFAS PFOA PFOS Free Test Report

RPET lid PFAS PFOA PFOS POPS Free Test Report

EC/EU Test Report – RPET Lid

EC/EU Test Report for PP lid

Why Bioleader® is Your Trusted Plastic-Free Paper Cup Supplier

Bioleader® delivers a full portfolio of plastic-free cup solutions supported by advanced barrier technologies and strict quality control. Our manufacturing system ensures consistent cup roundness, leak resistance, coating uniformity, and structural strength suitable for demanding beverage operations.

Why Choose Bioleader® for Plastic-Free Paper Cup Needs?

We offer strong production reliability, competitive wholesale pricing, breakthrough barrier technology, and fully recyclable or compostable material systems aligned with global sustainability policies.

Wholesale Orders for Plastic-Free Paper Cups

Bulk ordering provides stable supply for cafés and distributors, ensuring brand consistency across multiple outlets with customizable printing and flexible volume options.

Contact Bioleader® for Your Compostable Paper Cup Needs

Join the global movement toward zero-waste packaging.

Bioleader® offers:

📦 Bulk order support & fast delivery

✍️ Custom branding and OEM solutions

🌍 Worldwide eco-packaging compliance

FAQs of Bioleader's Paper Cups

Water-based coated cups use an aqueous dispersion instead of PE or PLA, creating a fully plastic-free barrier. They remain leak-resistant for hot and cold drinks while being easier to recycle and compost.

Yes—uncoated cups are ideal for certain cold or low-grease drinks and are made from food-grade paper. While they offer maximum recyclability, they are recommended for applications where moisture exposure is limited.

Water-based coatings are plastic-free, easier to repulp, and suitable for both recycling and composting systems. They offer similar performance to PLA and PE while dramatically improving end-of-life sustainability.

Water-based coated cups can safely handle typical hot beverage temperatures. They maintain structural stability and leak resistance without introducing plastic or petroleum-based components.

No. They are compatible with standard recycling streams and also break down in industrial composting facilities. Their plastic-free design ensures faster fiber recovery and cleaner waste processing.