In high-volume beverage service environments, paper cups are not simply disposable containers. For manufacturers supplying cafés, restaurants, food trucks, offices, event organisers, and beverage chains, paper cups are functional packaging components that must perform reliably under pressure. Durability, size accuracy, material performance, and manufacturing consistency all influence how these cups function once they reach real-world service conditions.

This article is written from the perspective of a paper cup manufacturer, focusing on how durable paper cups are designed, produced, and applied downstream. It explains sizing standards, material choices, production processes, hot and cold beverage performance requirements, and how customised paper cups are ultimately used by packaging brands and distributors serving different market segments.

What Are Customised Paper Cups?

Customised paper cups are disposable beverage containers manufactured from food-grade paperboard and finished with specific structural, material, and printing parameters. At the manufacturing level, these parameters are defined to meet beverage safety standards, prevent leakage, and maintain structural stability during use.

Unlike generic cups, customised paper cups are produced to support downstream branding requirements. Logos, colour systems, and messaging are applied during production so that packaging brands and distributors can integrate these cups into their own customer-facing solutions.

From a manufacturing perspective, the primary objective is functional reliability. Visual branding is secondary to ensuring that cups perform consistently across different beverage types, temperatures, and handling conditions.

Why Durability Matters in High-Volume Beverage Operations

In busy beverage operations, packaging failure creates immediate operational issues. Leaks, collapsed cups, inconsistent sizing, or poor insulation affect customer experience and slow down service workflows.

Durable double-wall paper cups help downstream operators maintain portion control, reduce waste, and limit service interruptions. Consistent cup specifications also allow distributors and beverage businesses to standardise procurement and forecasting across multiple service locations.

For manufacturers, durability is not a marketing feature but a production requirement that must be validated through material selection, forming accuracy, and quality control.

Understanding Paper Cup Sizes and Capacity Terminology

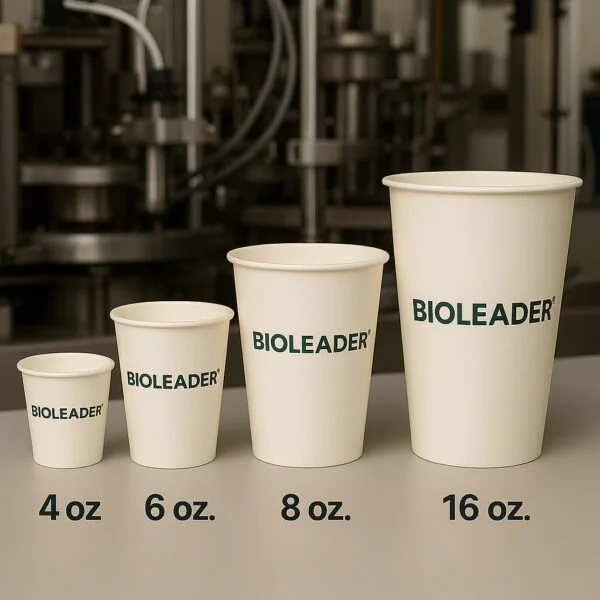

One of the most frequent sources of confusion in beverage packaging is cup sizing. Paper cups are typically measured in ounces (oz) or millilitres (ml), depending on regional conventions.

Millilitres are commonly used in the UK and Europe, while ounces remain standard in the United States and many international beverage programmes. Manufacturers often specify both units to support global supply chains and reduce ordering errors.

Common reference volumes include:

4 oz ≈ 120 ml

6 oz ≈ 180 ml

8 oz ≈ 240 ml

12 oz ≈ 355 ml

16 oz ≈ 475 ml

Selecting the correct size supports portion consistency, pricing alignment, and beverage presentation across different service formats.

Materials Used in Paper Cup Manufacturing

Paper cup durability is closely linked to material selection. Manufacturers adjust paperboard grades and barrier coatings based on beverage temperature, holding time, and expected handling conditions.

Food-grade paperboard forms the structural body of the cup. Heavier paperboard improves rigidity and insulation for hot drinks, while lighter grades are typically sufficient for cold beverages.

Moisture-resistant linings are required for all paper cups. Traditional polyethylene (PE) coatings remain widely used, while water-based and biodegradable coatings are increasingly specified where environmental considerations apply. These linings influence heat retention, condensation control, and recycling compatibility.

Performance Requirements for Hot and Cold Beverages

Hot beverages place specific demands on cup construction. Single-wall cups offer a lightweight and economical option but may require sleeves for high-temperature drinks. Double-wall and ripple-wall structures improve insulation and grip, reducing heat transfer to the user.

Cold beverages introduce different stresses, particularly condensation and prolonged contact with ice. Cold drink cups are designed to maintain shape and prevent leakage over extended holding times. Larger formats are often paired with flat or dome lids for iced coffees, juices, and soft drinks.

From a manufacturing standpoint, both hot and cold applications require precise control of forming, sealing, and rim rolling to ensure consistent performance.

Manufacturing Process Overview

The production of customised paper cups follows a controlled manufacturing sequence. Designs are printed using food-safe inks, then cut into blanks. These blanks are formed into cylinders, sealed along the side seam, and bonded to a circular base. The rim is rolled to create a reinforced drinking edge.

Throughout production, dimensional accuracy, sealing integrity, and structural strength are monitored to ensure that finished cups meet beverage-service requirements before packaging and shipment.

Downstream Application: Packaging Brands and Distributors

As a manufacturer from China, Bioleader produces paper cups at scale for beverage-service requirements, including material selection, barrier performance, printing consistency, and quality control. These paper cups are supplied to packaging brands and distributors across various markets, who integrate the cups into their own customised packaging solutions for cafés, events, takeaway services, and other high-traffic beverage scenarios.

For example, the bespoke paper cups in the UK, wholesale by a leading packaging distributor, incorporate Bioleader-manufactured paper cups into their range of packaging solutions tailored for foodservice operations. In this case, BoxPack UK focuses on local specifications, brand customisation, and client servicing while relying on Bioleader for consistent production standards and material performance.

Similarly, Custom Paper Cups in the USA leverages custom printing paper cups as part of their beverage packaging solutions, where they manage customer-specific branding and packaging design, which are produced by Bioleader. The company handles local market needs and ensures product availability and timely delivery for high-volume orders in the F&B sector.

Another example is Paper cups with lids from The Cosmetic Boxes – One packaging Spot, which integrates Bioleader paper cups into their global product portfolios, providing stable production quality and reliable material performance for large-scale packaging distributors. Their expertise lies in adapting the products for different regional markets, while Bioleader maintains responsibility for the upstream manufacturing, engineering, and compliance with product safety standards.

Through these implementations, Bioleader’s role remains focused on upstream manufacturing—covering engineering precision, forming accuracy, and ensuring product safety compliance—while downstream packaging brands and distributors focus on market-specific design adaptations, fulfilment, and customer support.

Sustainability Considerations

Environmental factors increasingly influence paper cup specifications. Manufacturers may offer recyclable paperboard and alternative barrier coatings to support sustainability targets set by downstream brands and beverage businesses.

Clear communication of material composition and disposal guidance helps align packaging choices with broader environmental policies without compromising performance requirements.

Final Thoughts

Durable paper cups are the result of manufacturing decisions made long before a beverage is served. Material selection, size accuracy, forming quality, and barrier performance all determine how cups perform in fast-moving beverage operations.

By understanding how paper cups are manufactured and applied downstream, packaging brands and beverage businesses can make informed decisions that support operational efficiency, product consistency, and reliable service across cafés, food trucks, offices, and events.