Biodegradable Pulp Trays for Meat, Fruits, Vegetables, and More

Biodegradable pulp trays are increasingly replacing plastic trays in supermarkets, delis, and fresh-food counters. Made from natural molded fiber, these trays provide excellent breathability, moisture control, and food-contact safety—making them ideal for meat, fruits, vegetables, bakery items, and ready-to-eat assortments. As countries strengthen PFAS policies and shift toward recyclable and compostable packaging, biodegradable serving trays offer a compliant, low-carbon alternative. Bioleader® provides food-grade pulp trays engineered for durability, shelf-life performance, and export-ready documentation for global distribution.

About Biodegradable Serving Trays

Bioleader® manufactures high-quality biodegradable serving trays engineered for fresh produce, chilled meat, seafood, bakery, and deli applications. Our bagasse pulp trays are produced using molded sugarcane and plant fibers that deliver natural breathability, rigidity, and moisture absorption—improving freshness and visual appeal on retail shelves. The product range includes molded pulp trays for meat, fruit trays, vegetable trays, and universal serving trays for supermarkets and food processors. All molded pulp trays are PFAS-free and comply with FDA, LFGB, and EN13432 compostability standards, ensuring safe food-contact performance and environmentally responsible disposal. Bioleader® supports global buyers with export-ready documentation and stable mass-production capabilities.

Best-Selling Biodegradable Pulp Trays for Meat, Fruit & Vegetable Packaging

Why Choose Bioleader® Biodegradable Serving Trays?

Bioleader® provides biodegradable serving trays designed for durability, chilled-food performance, and global compliance. Our molded-fiber technology ensures consistent strength, smooth edges, and reliable dimensional accuracy across large production runs. With PFAS-free materials, batch-level traceability, and international food-contact certifications, our pulp trays support retailers, processors, and distributors seeking to eliminate plastic while maintaining professional presentation and operational efficiency.

Key Features of Bioleader® Molded Pulp Trays

High Breathability & Moisture Management

The molded-fiber structure allows fresh produce and chilled meat to maintain better airflow, helping reduce condensation and preserve appearance in refrigerated displays.

Strong, Lightweight Structural Integrity

Designed to support fruits, vegetables, cuts of meat, snacks, and deli items without bending—ideal for retail handling, transport, and stocking.

Compostable & PFAS-Free Food Safety

Made from renewable plant fibers, the trays are fully compostable and certified food-safe, meeting global standards for packaging fresh and raw foods.

Versatile Formats for Produce & Meat Programs

Available in various depths, thicknesses, and cavity shapes, enabling optimized SKU planning for supermarkets, processors, and meal-prep operations.

Ideal for Supermarket & Deli Display

The natural texture enhances visual merchandising and supports premium product positioning across fresh and ready-to-eat categories.

Top Use Cases for Biodegradable Pulp Trays

Bioleader® biodegradable pulp trays provide reliable performance across fresh-food retail, chilled storage, and in-store display programs. Their molded-fiber breathability and structural strength make them ideal for a variety of produce and meat applications.

Meat & Protein Packaging

Suitable for beef, poultry, seafood, deli meats, and marinated cuts requiring safe, PFAS-free contact surfaces and stable shelf-life performance.

Fruit & Vegetable Display

Excellent for berries, tomatoes, leafy greens, cut vegetables, mushrooms, and mixed produce packs used in supermarkets and farmers’ markets.

Bakery, Deli & Grab-and-Go

Ideal for pastries, snack assortments, cold meals, and ready-to-eat items requiring clean presentation and easy handling throughout retail operations.

Bagasse Tray Vs. Plastic Tray(PP,PET) Vs. Foam (EPS) Tray— Material Comparison Table

| Feature / Material | Bagasse Tray | Plastic Tray (PP / PET) | Foam (EPS) Tray |

|---|---|---|---|

| Raw Material Source | Sugarcane fiber by-product | Petroleum-based plastic | Petroleum-based polystyrene |

| Recycle &Compostable | Compostable (industrial & home) | Not compostable; Recyclable (PP), Not recyclable (PET) | Not recyclable or compostable |

| Heat Resistance | ~10°C to 120°C | PP: -20°C to 120°C, PET: -20°C to 70°C | ~ -20°C to 90°C |

| Water Resistance | Moderate | Excellent | Good |

| Oil Resistance | Good | PP: Excellent, PET: Good | Moderate |

| Microwave-safe | Yes (short-time heating) | Yes (short-time heating) | No |

| Strength & Rigidity | Good, fibrous structure | PP: High durability, PET: High clarity | Very fragile |

| Toxicity & Chemical Safety | Natural fiber, no chemical release when heated | PP: Food-safe but may release trace compounds at high heat, PET: Safe for cold use only | Releases styrene fumes when heated, banned/restricted in many countries |

| Environmental Impact | Very low carbon footprint | High carbon footprint | Very high carbon footprint |

| Typical Applications | Takeout trays, food trays, meal trays, sushi trays | Plates, trays, clamshells, meal boxes, food packaging | Cheap takeaway food packaging, disposable trays |

| Eco Score | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

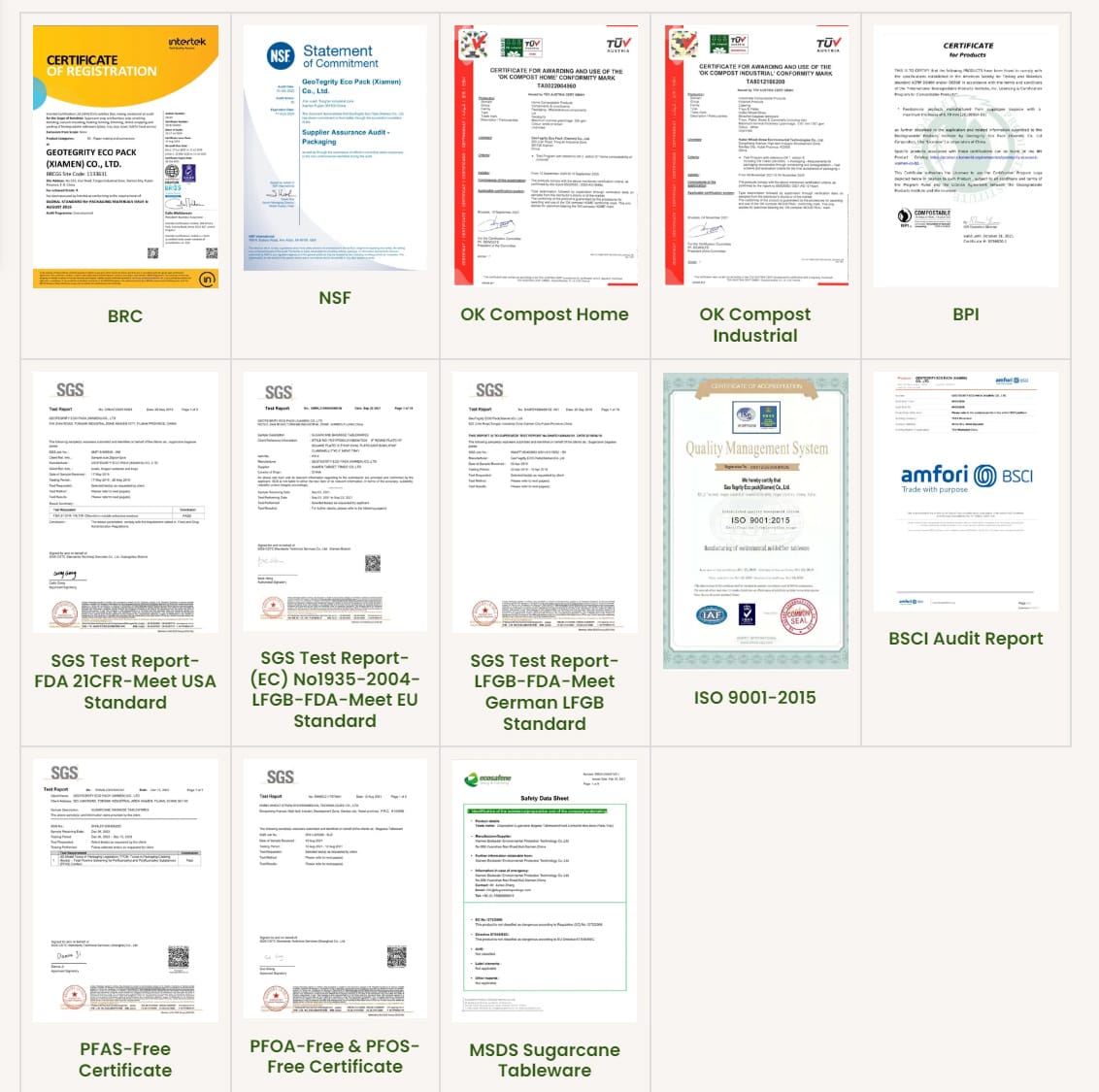

♻️ Certified for Safety, Compostability, Performance & Sustainability

All Bioleader® molded pulp trays come with full compliance documentation, ensuring global food-contact safety and compostability readiness.

Certified by leading international authorities:

✅OK-Compost (TÜV Austria), EN13432 & ASTM D6400: Certified for home, industrial composting, and meets international standards.

✅BRC & NSF: Food-grade safety certifications.

✅FDA & SGS: Approved for food-safe use.

✅ISO & BSCI Certified Facilities: Produced in facilities focused on water conservation, carbon reduction, and social responsibility.

Biodegradable & Renewable: Made from sugarcane residue, reducing landfill waste and eliminating plastic contamination in foodservice.

These certifications provide buyers with reliable proof of safety, consistency, and long-term environmental performance across all fresh-food programs.

Why Bioleader® Is Your Trusted Molded Pulp Trays Supplier

Bioleader® is one of China’s top manufacturers of molded pulp trays, supplying supermarket chains, food processors, fruit distributors, and fresh-produce exporters in more than 60 countries. Our ISO- and BSCI-certified facilities operate advanced molded-fiber lines capable of producing high-volume, multi-SKU programs with strong QC consistency. We specialize in PFAS-free formulations, global compliance documentation, private-label customization, and stable production planning—making Bioleader® a dependable partner for sustainable fresh-food packaging solutions.

Compliance Insight: Why Biodegradable Pulp Trays Are Becoming a Retail Standard

With global regulations tightening around PFAS restrictions, single-use plastics, and food-contact

safety requirements, retailers and processors are shifting to molded pulp solutions. Biodegradable

pulp trays align with EN13432, FDA, and LFGB standards, offering a compliant, scalable alternative

for fresh-food packaging portfolios.

Regulatory Pressure on Plastic Packaging

Regions including the EU, GCC, and North America have strengthened restrictions on non-recyclable

plastic trays—particularly EPS, black PET, and PFAS-treated formats. Retailers face increased

compliance risks and eco-tax exposure when continuing legacy materials.

Molded pulp trays, supported by EN13432 or ASTM D6400 frameworks, offer a compliant path for modern

fresh-food operations.

Fresh-Food Performance Advantages

- Natural breathability helps reduce condensation for meat and produce.

- Rigid molded-fiber walls support stacking, long transport routes, and chilled display.

- Molded pulp can reduce CO₂ emissions by 40–70% compared to plastic trays, based on LCA data.

These attributes make biodegradable pulp trays a strong fit for supermarkets, delis, and processors.

Documentation for Global Importers

Major retailers increasingly require PFAS-free verification, food-contact test reports, and

compostability certificates. Gaps in documentation can disqualify suppliers from tenders and

private-label programs.

Bioleader® provides a complete compliance package, paired with ISO and BSCI production capability,

ensuring stable approval for international sourcing teams.

Strategic Value for Retail & Processing Chains

Standardizing biodegradable pulp trays supports ESG reporting, regional regulation alignment, and

portfolio simplification across produce, bakery, deli, and meat categories.

With scalable capacity, private-label customization, and PFAS-free molded-fiber systems, Bioleader®

is positioned as a strategic partner for long-term packaging transformation.

Contact Bioleader® for Eco Green & Sustainable Packaging

At Bioleader®, we support businesses in making sustainable choices with eco-friendly packaging solutions that reduce your environmental impact.

Bioleader® offers:

Bulk Orders & Fast Delivery: Efficient order handling and quick shipping worldwide.

Custom Branding & OEM: Tailored packaging solutions with your brand.

Eco-Packaging Compliance: Global certifications ensuring adherence to environmental standards.

Looking for quality eco-friendly packaging? Contact us for catalogs, quotes, or design assistance.

FAQs of Bioleader’s Sugarcane Bagasse Eco Pulp Trays

Yes. Bioleader® pulp trays meet FDA and LFGB food-contact standards and contain no added PFAS, making them safe for meat, fruits, vegetables, and chilled foods.

Absolutely. They perform well in refrigerated and chilled environments and help reduce moisture buildup, improving freshness and shelf-life consistency.

Yes. Bioleader® trays meet EN13432 compostability criteria and are made from plant fibers that naturally break down without generating microplastics.

Yes. For most fresh-produce and protein SKUs, molded pulp trays provide comparable strength and display performance while offering improved sustainability and compliance.

Yes. We support OEM solutions including custom sizes, embossing, branding, and tailored shapes for produce lines, deli sections, and protein categories.