Introduction: Why Cup Materials Are More Important Than Ever

Walk into any café, juice bar, or event venue, and disposable cups are everywhere. They hold hot lattes, iced teas, smoothies, and sparkling sodas. But in 2025, one crucial detail determines whether these cups end up as waste or as part of a circular economy: what they are made of.

Many businesses see labels like “biodegradable” or “compostable” and assume they mean the same thing. In reality, the distinction has huge implications for compliance with global plastic bans, environmental impact, and customer perception.

This article breaks down the key differences, explores how compostable cups are designed and manufactured, provides scientific data on their decomposition, and highlights why switching to certified solutions from suppliers like Bioleader® is both an environmental responsibility and a smart business move.

What Is the Difference Between Biodegradable and Compostable Cups?

At first glance, “biodegradable” and “compostable” look similar, but they carry very different meanings in environmental science and regulation.

Biodegradable cups: Made from materials that break down naturally through microbial action. However, “biodegradable” is a broad term with no strict timeframe. Some biodegradable plastics may take 10, 20, or even 50 years to fragment, and many only degrade into microplastics under sunlight or heat—posing risks to oceans and soil.

Compostable cups: A certified category defined by standards such as EN13432 (EU) and ASTM D6400 (USA). Compostable cups must disintegrate within 90–180 days in controlled composting facilities, turning into CO₂, water, and nutrient-rich biomass without leaving toxic residues.

Comparative Overview

| Feature | Biodegradable Cups | Compostable Cups |

|---|---|---|

| Breakdown Time | Years or decades (varies) | 90–180 days (industrial composting) |

| End Products | Often microplastics, CO₂, residue | CO₂, water, biomass (non-toxic) |

| Certification Standards | None required | EN13432, ASTM D6400, BPI, TÜV Austria |

| Consumer Perception | “Green” but vague | Trusted, backed by scientific testing |

| Legal Acceptance (EU/US) | Increasingly restricted | Accepted and encouraged |

Expanded Insight:

For global buyers, this difference is more than technical—it directly affects import approvals, food-safety compliance, and customer trust. For example, a “biodegradable” cup made from oxo-degradable plastic may be rejected in the EU, while a certified compostable cup is welcomed in eco-regulated markets.

What Are Compostable Cups Lined With?

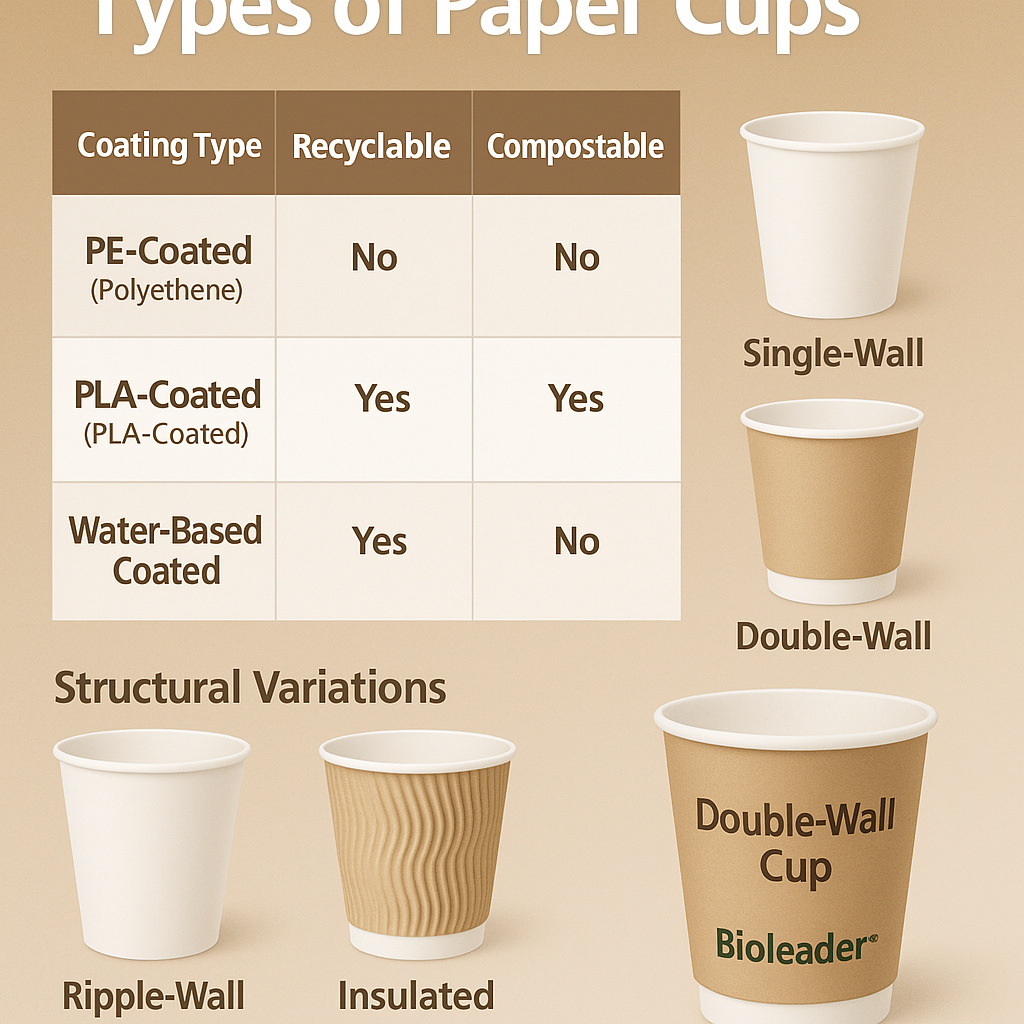

If you’ve ever torn open a paper cup, you’ve noticed a thin plastic film inside. Traditional paper cups are lined with polyethylene (PE), which makes them waterproof but nearly impossible to recycle.

Compostable cups replace this with advanced barrier technologies:

PLA (Polylactic Acid) Lining

Derived from corn starch or sugarcane.

Provides water and oil resistance.

Fully compostable in industrial facilities.

Heat resistance: up to 85°C, ideal for hot drinks.

Aqueous Coating

A water-based dispersion barrier.

Contains no plastic.

Already adopted in European markets where plastic-free claims are essential.

Bio-based Resin Blends

Specialty coatings that improve grease and temperature resistance.

Applied for premium applications such as branded coffee chains.

Bioleader®’s approach: Our compostable paper cups use PLA lining for reliable leak-proof performance while meeting EN13432 and ASTM D6400 compostability standards. This combination of strength and sustainability makes them ideal for restaurants and cafés serving both hot and cold drinks.

How Are Compostable Plastic Cups Made?

Compostable clear PLA cups, often used for smoothies and cold beverages, are made primarily from PLA.

The Manufacturing Process

| Stage | Description |

|---|---|

| Raw Material | Corn starch, cassava, or sugarcane is harvested and processed. |

| Fermentation | Carbohydrates are converted into lactic acid via microbial fermentation. |

| Polymerization | Lactic acid molecules are linked to form polylactic acid (PLA) resin. |

| Shaping | PLA resin is injection-molded, thermoformed, or extruded into cup forms. |

| Quality Check | Finished cups are tested for strength, clarity, and compostability. |

Expanded Insight

Compared to PET or PP plastic, which derive from fossil fuels, PLA has a carbon footprint 60–70% lower. For every ton of PLA cups produced, up to 1.5 tons of CO₂ emissions are avoided compared to traditional plastic. This makes PLA not only compostable at the end of life but also environmentally superior from the start of production.

PLA Compostable Cups: Uses, Applications, and Advantages

PLA compostable cups are particularly popular in the foodservice, catering, and beverage industries because they combine functionality with eco-certification. Their clarity and durability make them the go-to choice for cold beverages such as smoothies, iced coffee, bubble tea, milkshakes, fruit juices, cocktails, and even cold desserts like parfaits. Event organizers and quick-service restaurants favor PLA cups because they provide the same crystal-clear presentation as PET plastic while meeting compostable standards.

Key Advantages of PLA Cups:

Transparency & Branding: PLA cups showcase colorful beverages just like traditional plastic, making them attractive for marketing and custom printing.

Eco-Certification: Fully compliant with EN13432 and ASTM D6400, meaning they break down in industrial composting facilities within 90–120 days.

Versatility: Available in multiple sizes (8oz–32oz) with flat or dome lids, making them suitable for cafés, juice bars, food trucks, and large events.

Lower Carbon Footprint: Compared to petroleum-based PET, PLA cups cut greenhouse gas emissions by up to 60–70% during production.

Consumer Preference: A growing number of customers choose outlets that use compostable packaging, boosting brand image and customer loyalty.

👉 For importers and distributors, sourcing PLA cold cups manufacturer direct ensures consistent supply, customizable designs, and compliance with strict regulations in Europe, North America, and Asia-Pacific markets.

Why Biodegradable vs Compostable Matters for Businesses

The difference is more than semantics—it impacts business compliance, costs, and brand equity.

Regulatory compliance

The EU Single-Use Plastics Directive bans “biodegradable” plastic claims without certification.

Canada’s 2024 plastics ban and several U.S. states require proof of compostability.

Buyers risk fines or import rejection if packaging is mislabeled.

Customer trust

A 2024 survey found 72% of consumers actively check for compostable certifications on cups and packaging.

Misleading claims can trigger backlash on social media.

Waste management

Compostable cups can be collected with food waste, reducing landfill disposal fees.

Restaurants using compostable packaging report 15–20% savings in waste hauling costs.

Brand value

Compostable packaging strengthens ESG reports.

Helps win contracts with eco-conscious corporate clients and event organizers.

Global Trends in Compostable Cups

The compostable cup market is projected to grow at 13–15% CAGR through 2030.

| Region | Trend |

|---|---|

| Europe | Coffee chains shifting to PLA and aqueous-lined cups to meet local waste directives. |

| North America | University campuses and “zero waste” cities are adopting certified compostable cups. |

| Asia-Pacific | China scales PLA cup exports; Japan and Korea test water-based coatings. |

| Middle East & LATAM | Food delivery platforms drive demand for compostable cups bulk supplier models. |

Expanded Insight:

Global buyers are realizing that compostable cups bulk supplier contracts are not just about sustainability—they are strategic. Many importers in the Middle East and Latin America are signing multi-year supply agreements with Chinese manufacturers like Bioleader® to lock in certified, price-stable, and regulation-compliant products ahead of tightening local bans.

Scientific Insights: How Fast Do Compostable Cups Break Down?

Decomposition speed varies by material and environment.

| Material | Industrial Composting | Home Composting | Landfill Conditions |

|---|---|---|---|

| PLA Cold Cups | 90–120 days | 6–12 months | Little to no change |

| PLA-Lined Paper Cups | 90–100 days | 6–10 months | Very slow |

| Bagasse Fiber Cups | 60–90 days | 2–4 months | Very slow |

Expanded Insight:

Scientific studies show that bagasse cups decompose 30% faster than PLA cups under home composting conditions because they are made from natural plant fibers. PLA requires higher temperatures (55–60°C) to break down efficiently, which makes industrial composting the best pathway. This distinction is critical for buyers targeting regions where home composting is more common versus regions with municipal composting infrastructure.

Buyer Considerations: Cost, Performance, and Supply Chain

Cost: Compostable cups are typically 10–20% more expensive than plastic, but buyers offset this through bulk purchasing and reduced waste management fees.

Performance:

PLA-lined cups: reliable for hot drinks up to 85°C.

Bagasse cups: withstand higher heat, grease, and are microwave-safe.

Supply chain: Partnering with a sustainable disposable cups factory ensures:

Consistent quality

Third-party certifications

Export documentation

Bioleader®’s Certified Compostable Cup Solutions

Bioleader® offers a comprehensive portfolio tailored for restaurants, cafés, caterers, and importers.

| Product Type | Size Range | Applications | Features |

| PLA Compostable Cold Cups | 8oz–32oz | Smoothies, iced coffee, juice | Crystal-clear, strong, compostable with lids |

| PLA-Lined Compostable Paper Cups | 6oz–16oz | Coffee, tea, hot beverages | Leak-proof, customizable branding |

|

|

Expanded Insight

For global buyers, choosing Bioleader® means more than sourcing cups—it’s securing compliance, branding flexibility, and supply chain reliability. With BPI, EN13432, ASTM D6400, and TÜV Austria certifications, Bioleader® cups can be imported into the strictest eco-regulated markets. Our factory-direct model allows competitive wholesale pricing, while our OEM/ODM service lets clients design branded solutions without compromising sustainability.

FAQs

Are compostable cups microwave safe?

Bagasse fiber cups are microwave-safe, lasting 2–3 minutes at standard heating without leakage. PLA-lined paper cups are safe for hot drinks up to 85°C but should not be microwaved, as PLA softens under high heat. Buyers should match cup type to intended use.

Can compostable cups hold hot drinks?

Yes, certified compostable cups can handle hot beverages. PLA-lined paper cups safely hold coffee and tea at 70–85°C, while bagasse fiber cups resist even higher heat and oil content, making them ideal for soups and hot chocolate in takeaway services.

How long do compostable cups take to decompose?

In industrial composting facilities (55–60°C), PLA cold cups decompose in 90–120 days, while bagasse cups fully break down in 60–90 days. In home composting, the process takes longer—6–12 months for PLA and 2–4 months for bagasse.

Do compostable cups cost more than plastic cups?

Yes, compostable cups typically cost 10–20% more than conventional plastic cups. However, bulk procurement reduces the price gap, and restaurants often save on landfill disposal fees. Many buyers see lifecycle savings and stronger ESG value as compensation.

Where can I buy bulk compostable cups for restaurants?

Certified compostable cups are available from wholesale manufacturers like Bioleader®, which supplies PLA cold cups, PLA-lined hot drink cups, and bagasse fiber cups. With EN13432, ASTM D6400, and BPI certifications, our products are export-ready for Europe, North America, and Asia-Pacific markets.

Conclusion

The terms “biodegradable” and “compostable” are not interchangeable. For buyers in 2025, only certified compostable cups ensure compliance with global bans, environmental performance, and customer trust.

From PLA cold cups manufacturer solutions to paper hot drink cups, Bioleader® enables businesses worldwide to transition smoothly into a sustainable future. Choosing compostable cups is not just about replacing plastic—it’s about reshaping foodservice packaging with materials that truly return to nature.

Reference

European Commission — Single-Use Plastics Directive, 2024.

ASTM International — ASTM D6400 Standard Specification for Compostable Plastics, 2023.

European Bioplastics Association — Market Data Report on Bioplastics, 2024.

Biodegradable Products Institute (BPI) — Certification Guidelines, 2024.

Ellen MacArthur Foundation — The New Plastics Economy Report, 2023.

U.S. Environmental Protection Agency (EPA) — Sustainable Materials Management Report, 2024.

TÜV Austria — Industrial and Home Compostability Testing Protocols, 2023.

International Solid Waste Association (ISWA) — Composting and Biodegradable Packaging Study, 2023.

Smith, J. — “Comparative LCA of PLA and PET Cups,” Journal of Cleaner Production, 2024.

Biodegradable vs Compostable Cups: Insights & Buyer Considerations

Key Insight: Choosing between biodegradable and compostable cups in 2025 is no longer about definitions—it’s about compliance, consumer trust, and global supply options. Here’s what buyers need to know:

- How to Tell the Difference: Biodegradable cups may take years to break down and can leave microplastics. Compostable cups meet EN13432/ASTM D6400 and fully decompose in 90–180 days under industrial composting.

- Why Certification Matters: Only certified compostable cups are legally accepted in the EU, Canada, and many U.S. states. Mislabeling “biodegradable plastic” risks import rejection.

- What Are They Lined With: Compostable paper cups use PLA or aqueous coatings instead of PE, ensuring leak resistance while staying compostable.

- Options for Different Uses: PLA clear cups are best for cold drinks and branding; PLA-lined paper cups for hot coffee and tea; bagasse fiber cups for heat-intensive or microwave-safe applications.

- Considerations for Buyers: Costs are 10–20% higher than plastic, but bulk procurement and reduced landfill fees balance this. Partnering with a certified factory ensures supply chain stability and compliance for export.

- Market Trend: Global demand for compostable cups is growing at 13–15% CAGR through 2030, driven by plastic bans and eco-conscious consumers. Importers who secure certified supply now gain long-term advantage.